Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Ordnance Mechanic interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Ordnance Mechanic so you can tailor your answers to impress potential employers.

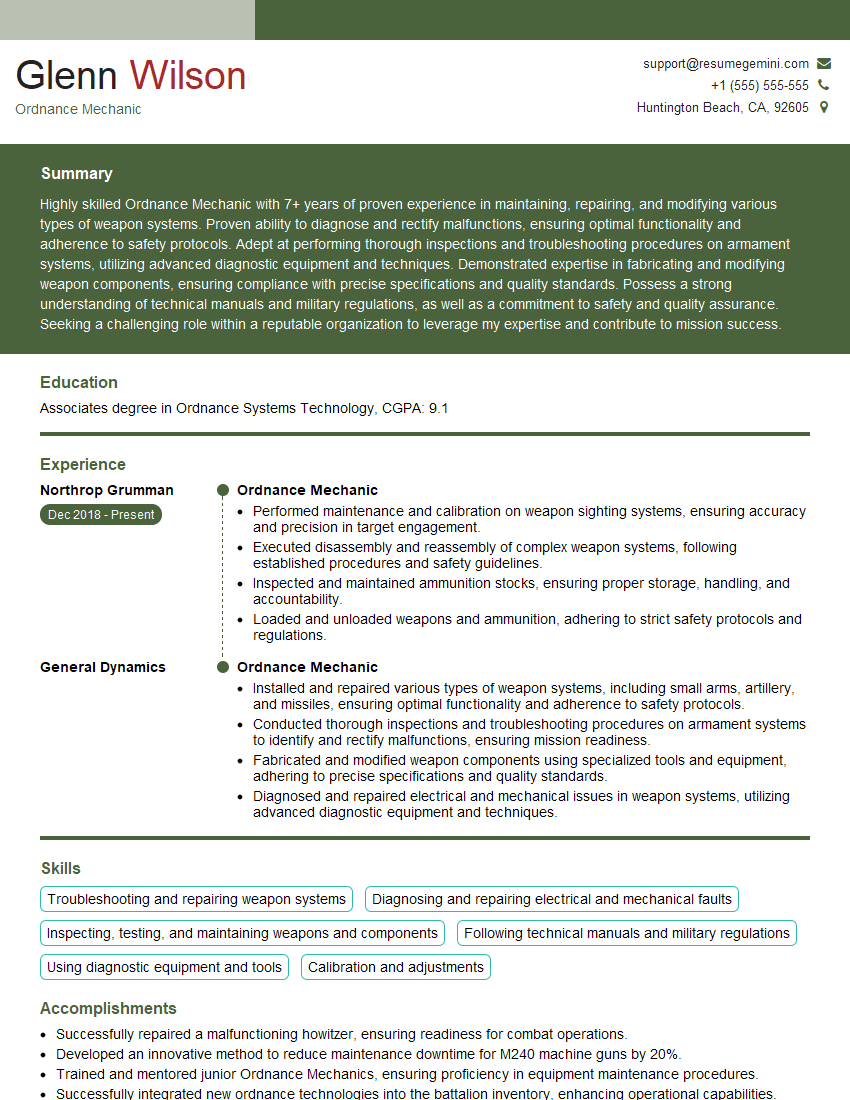

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ordnance Mechanic

1. Explain the process of disassembling and reassembling a weapon system?

Upon receiving a weapon system, I initiate the disassembly process by identifying its specific components. Utilizing proper tools and techniques, I carefully dismantle each component, ensuring no parts are misplaced or damaged. Once disassembly is complete, I conduct a thorough inspection of all parts, noting any potential issues or areas requiring attention.

Proceeding to the reassembly phase, I meticulously align and assemble the components in the correct order and orientation. I employ the necessary tools and techniques to ensure proper fit and function. Upon completion, I perform comprehensive operational checks to verify the weapon system’s functionality and safety.

2. Describe the inspection procedures you follow when servicing weapons systems?

Visual Inspection

- Thoroughly examine the weapon system’s exterior surfaces for dents, scratches, cracks, or any visible damage.

- Inspect the barrel, chamber, and bore for signs of corrosion, fouling, or obstructions.

- Check the stock, grip, and handguard for any loose or damaged components.

Functional Inspection

- Verify the weapon system’s functionality by conducting a series of dry-fire cycles and live-fire tests.

- Check the trigger pull, safety mechanisms, and magazine release for proper operation.

- Ensure the weapon system cycles correctly and ejects spent casings effectively.

Detailed Inspection

- Disassemble the weapon system and inspect each individual component for wear, damage, or corrosion.

- Clean and lubricate all components as necessary.

- Reassemble the weapon system and conduct a final functional inspection.

3. How do you prioritize and manage your workload when faced with multiple tasks and deadlines?

To effectively manage my workload and meet deadlines, I employ a systematic approach. Initially, I assess the urgency and importance of each task based on established priorities or client requirements. I then create a prioritized list, considering the time constraints and resources available.

To enhance efficiency, I utilize time management techniques such as breaking down large tasks into smaller, manageable chunks. This allows me to focus on one task at a time and avoid feeling overwhelmed. I also allocate time slots throughout the day for specific tasks, ensuring progress is made on all fronts.

4. What is the importance of maintaining accurate and up-to-date documentation for weapons systems?

- Safety: Proper documentation ensures that all maintenance and repair procedures are performed correctly, minimizing the risk of accidents or malfunctions.

- Compliance: Accurate records demonstrate adherence to regulatory requirements and industry standards, ensuring compliance with legal and ethical guidelines.

- Traceability: Detailed documentation allows for tracking the history and maintenance of weapons systems, facilitating troubleshooting and quality control.

- Knowledge Transfer: Up-to-date documentation serves as a valuable resource for training new personnel and transferring knowledge within the organization.

- Accountability: Clear documentation establishes accountability for all maintenance and repair work performed, ensuring transparency and responsibility.

5. How do you stay abreast of technological advancements and industry best practices in weapons systems maintenance?

- Continuing Education: Regularly attending industry conferences, workshops, and seminars to acquire knowledge on emerging technologies and best practices.

- Trade Publications and Journals: Subscribing to relevant publications and industry journals to stay informed about the latest developments and advancements.

- Online Resources: Utilizing online platforms, forums, and technical websites to access up-to-date information and connect with other professionals in the field.

- Manufacturer Training: Participating in training programs offered by manufacturers to gain specialized knowledge on specific weapons systems and maintenance techniques.

- Networking: Engaging with colleagues, industry experts, and professional organizations to exchange knowledge and stay informed about industry trends.

6. Describe a situation where you faced a technical challenge while servicing a weapons system. How did you resolve it?

During a routine inspection of a complex weapons system, I encountered an issue with its electronic control unit. The system was experiencing intermittent failures, and initial diagnostic tests did not reveal any apparent cause. I consulted the technical manuals and troubleshooting guides, but the solution remained elusive.

To resolve the issue, I systematically eliminated potential causes by isolating different components and conducting thorough testing. I also reached out to colleagues and industry experts to seek their insights and recommendations. After several hours of troubleshooting, I identified a loose connection within the control unit. I carefully repaired the connection, reassembled the system, and conducted rigorous testing to verify its functionality. The issue was permanently resolved, and the weapons system was returned to service without further problems.

7. What are the safety protocols you follow when working with weapons systems?

- Treat all weapons as if they are loaded: Never point a weapon at anything you do not intend to shoot.

- Keep your finger off the trigger: Only place your finger on the trigger when you are ready to fire.

- Be aware of your surroundings: Know what is in front of and behind your target before firing.

- Wear proper safety gear: Use ear and eye protection when operating or servicing weapons systems.

- Follow established safety procedures: Adhere to all guidelines and protocols for handling, storage, and maintenance of weapons systems.

8. How do you ensure the proper storage and handling of ammunition?

- Secure storage: Ammunition must be stored in a locked, climate-controlled environment to prevent unauthorized access and deterioration.

- Proper handling: Always handle ammunition with care to avoid accidental discharge or damage.

- First in, first out: Use the oldest ammunition first to ensure proper rotation and prevent deterioration.

- Inspect regularly: Periodically inspect ammunition for signs of damage, corrosion, or moisture.

- Follow manufacturer guidelines: Adhere to the manufacturer’s instructions for proper storage and handling of specific ammunition types.

9. Describe your experience in troubleshooting and repairing weapons systems.

Throughout my career, I have extensively troubleshooted and repaired various weapons systems. I possess a systematic approach to troubleshooting, utilizing diagnostic tools and techniques to identify and resolve issues efficiently. I am proficient in repairing both mechanical and electronic components, ensuring the restoration of optimal functionality.

For instance, I once encountered a malfunctioning weapons system that exhibited erratic firing behavior. Through a series of diagnostic tests, I isolated the issue to a faulty firing pin. I replaced the firing pin with a new one, and after thorough testing, the system functioned flawlessly.

10. How do you prioritize the maintenance and repair of weapons systems based on their criticality and operational requirements?

- Criticality assessment: I evaluate the importance and functionality of each weapons system to determine its criticality level.

- Operational requirements: I consider the operational schedule and mission requirements to assess the urgency of maintenance or repairs.

- Resource allocation: I allocate resources, including personnel and equipment, based on the criticality and urgency of the tasks.

- Scheduling: I develop and maintain a maintenance schedule that prioritizes the most critical systems and ensures timely completion of all tasks.

- Continuous monitoring: I regularly monitor the status of all weapons systems to identify any emerging issues or potential risks.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ordnance Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ordnance Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Ordnance Mechanic is an essential role in the military or law enforcement, responsible for maintaining and repairing a wide range of weapons, vehicles, and equipment. The job requires a high level of technical expertise and a thorough understanding of firearms and ammunition. Some of the key job responsibilities include:

1. Inspect and Maintain Weapons

Inspecting and maintaining weapons is a crucial part of an Ordnance Mechanic’s role. They are responsible for:

- Inspecting weapons for damage, wear, and corrosion

- Cleaning and lubricating weapons

- Replacing damaged or worn parts

- Ensuring weapons are safe and operational

2. Troubleshoot and Repair Vehicles

Ordnance Mechanics are also responsible for troubleshooting and repairing vehicles. This includes:

- Diagnosing problems with vehicles

- Repairing engines, transmissions, and other mechanical components

- Replacing damaged parts

- Ensuring vehicles are safe and operational

3. Handle and Store Ammunition

Ordnance Mechanics are responsible for handling and storing ammunition. This includes:

- Storing ammunition in a safe and secure location

- Inspecting ammunition for damage or defects

- Issuing ammunition to authorized personnel

- Ensuring ammunition is properly accounted for

4. Train Personnel

Ordnance Mechanics may also be responsible for training personnel on the safe use and maintenance of weapons and equipment.

- This includes teaching personnel how to disassemble, clean, and reassemble weapons

- Teaching personnel how to operate and maintain vehicles and equipment

- Teaching personnel about the safe handling and storage of ammunition

Interview Tips

Preparing for an Ordnance Mechanic interview can be challenging, but by following some simple tips, you can increase your chances of success.

1. Research the Company and Position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company and position on the company’s website, Glassdoor, and other online resources.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Take some time to practice answering these questions in a clear and concise manner. You can practice with a friend or family member, or you can record yourself answering the questions and then play back the recording to identify areas for improvement.

3. Highlight Your Skills and Experience

In your interview, be sure to highlight your skills and experience that are relevant to the position you are applying for. For example, if you have experience inspecting and maintaining weapons, be sure to mention this in your interview. You can also mention any training or certifications that you have.

4. Be Enthusiastic and Professional

It is important to be enthusiastic and professional throughout the interview process. This shows the interviewer that you are interested in the position and that you are a hard worker. Be polite and respectful to the interviewer, and be sure to ask questions about the company and the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ordnance Mechanic interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.