Are you gearing up for a career in Ordnance Truck Installation Mechanic? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Ordnance Truck Installation Mechanic and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

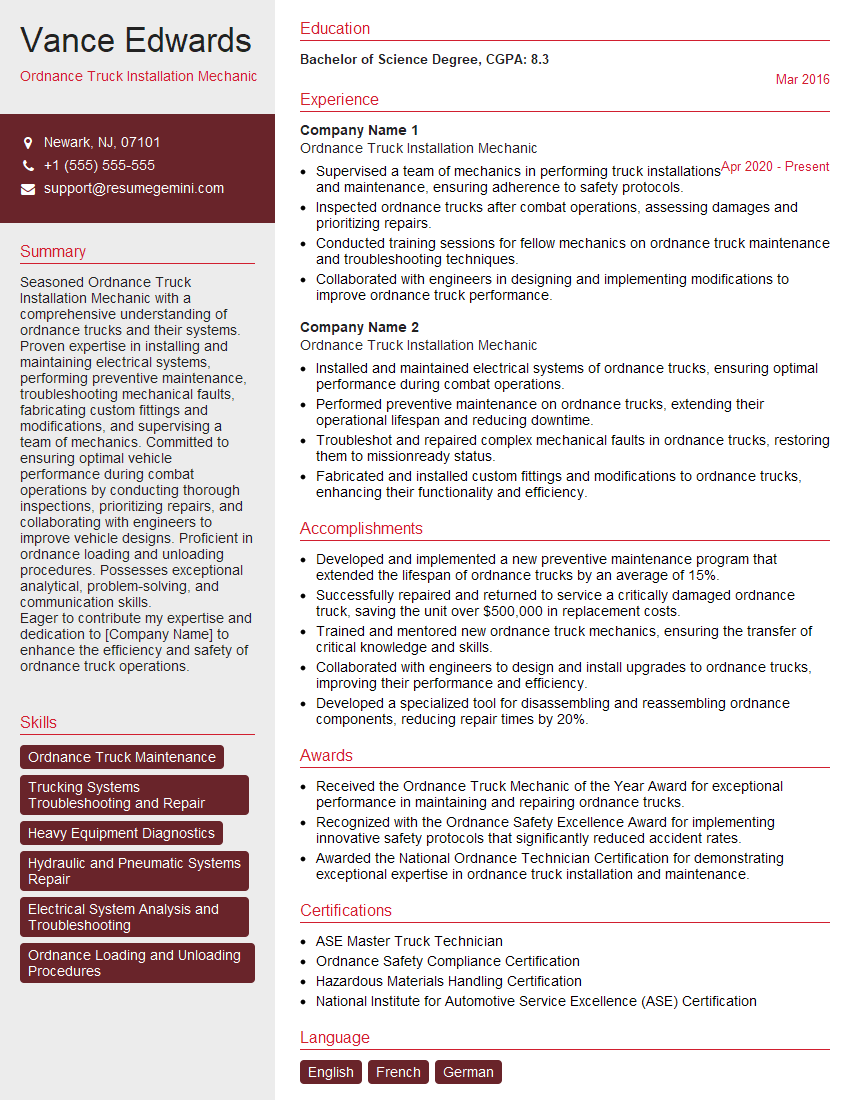

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ordnance Truck Installation Mechanic

1. What are the key steps involved in installing a new radio system on a military truck?

The key steps involved in installing a new radio system on a military truck are as follows:

- Remove the old radio system: This involves disconnecting the power supply, removing the antenna, and uninstalling the radio unit.

- Prepare the new radio system: This involves unpacking the new radio system, checking the components, and assembling the unit.

- Mount the new radio system: This involves securing the radio unit to the truck’s chassis or dash, and connecting the power supply and antenna.

- Configure the new radio system: This involves programming the radio with the correct frequencies and settings, and testing the system to ensure it is working properly.

- Train the user on the new radio system: This involves providing the user with instructions on how to operate the radio, and answering any questions they may have.

2. What are the different types of electrical systems used on military trucks?

12-volt systems

- Used on most light-duty military trucks and vehicles.

- Provides power for starting the engine, running the lights, and operating other electrical accessories.

24-volt systems

- Used on medium-duty to heavy-duty military trucks and vehicles.

- Provides more power for starting large engines and operating heavy-duty electrical equipment.

Hybrid systems

- Combine both 12-volt and 24-volt systems to provide power for different applications.

- For example, a hybrid system might use a 12-volt system to power the lights and accessories, and a 24-volt system to power the engine and other heavy-duty equipment.

3. What are the different types of hydraulic systems used on military trucks?

- Open-center hydraulic systems: These systems use a pump to circulate hydraulic fluid throughout the system, regardless of whether or not any hydraulic components are active.

- Closed-center hydraulic systems: These systems use a pump to circulate hydraulic fluid only when a hydraulic component is active.

- Load-sensing hydraulic systems: These systems use a sensor to detect the load on the hydraulic system, and adjust the pump output accordingly.

4. What are the different types of suspension systems used on military trucks?

- Leaf spring suspensions: These suspensions use leaf springs to support the weight of the truck and absorb shocks from the road.

- Coil spring suspensions: These suspensions use coil springs to support the weight of the truck and absorb shocks from the road.

- Torsion bar suspensions: These suspensions use torsion bars to support the weight of the truck and absorb shocks from the road.

- Air suspensions: These suspensions use air bags to support the weight of the truck and absorb shocks from the road.

5. What are the different types of braking systems used on military trucks?

- Hydraulic brake systems: These systems use hydraulic fluid to transfer force from the brake pedal to the brake pads.

- Air brake systems: These systems use compressed air to transfer force from the brake pedal to the brake pads.

- Electric brake systems: These systems use electric motors to transfer force from the brake pedal to the brake pads.

6. What are the different types of steering systems used on military trucks?

- Manual steering systems: These systems use a steering wheel to turn the wheels of the truck.

- Power steering systems: These systems use a hydraulic pump to assist the driver in turning the wheels of the truck.

7. What are the different types of transmission systems used on military trucks?

- Manual transmissions: These transmissions require the driver to shift gears manually.

- Automatic transmissions: These transmissions automatically shift gears based on the speed of the truck and the load on the engine.

8. What are the different types of differential systems used on military trucks?

- Open differentials: These differentials allow the wheels on each side of the truck to turn independently.

- Limited-slip differentials: These differentials allow the wheels on each side of the truck to turn independently, but provide some resistance to slipping.

- Locking differentials: These differentials lock the wheels on each side of the truck together, so that they turn at the same speed.

9. What are the different types of winches used on military trucks?

- Mechanical winches: These winches use a gearbox and a set of gears to wind and unwind the cable.

- Hydraulic winches: These winches use a hydraulic motor to wind and unwind the cable.

- Electric winches: These winches use an electric motor to wind and unwind the cable.

10. What are the different types of cranes used on military trucks?

- Hydraulic cranes: These cranes use hydraulic cylinders to lift and lower the boom.

- Electric cranes: These cranes use electric motors to lift and lower the boom.

- Telescopic cranes: These cranes have a boom that can be extended or retracted, allowing them to reach greater heights.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ordnance Truck Installation Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ordnance Truck Installation Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ordnance Truck Installation Mechanics play a crucial role in ensuring the proper functioning of ordnance trucks. Their responsibilities encompass various technical aspects, including installation, maintenance, and repair of ordnance systems and components.

1. Ordnance System Installation

Install, test, and ensure the correct integration of ordnance systems, such as weapons, ammunition, and fire control equipment, on trucks.

- Follow prescribed technical specifications and diagrams.

- Use specialized tools and equipment for precision installation.

2. System Maintenance and Repair

Conduct regular inspections, maintenance, and repairs of ordnance systems and associated components.

- Identify and diagnose faults in electrical, hydraulic, and mechanical systems.

- Overhaul, replace, or repair damaged components as necessary.

3. Troubleshooting and Problem-Solving

Troubleshoot and resolve complex technical issues related to ordnance systems.

- Analyze system performance data and pinpoint root causes of malfunctions.

- Develop and implement effective solutions to restore system functionality.

4. Technical Support

Provide technical support and guidance to operators and maintenance personnel.

- Explain system operation and troubleshoot potential issues.

- Develop and update technical documentation and procedures.

Interview Tips

To ace an interview for an Ordnance Truck Installation Mechanic position, candidates should prepare thoroughly and showcase their technical skills, troubleshooting abilities, and commitment to safety.

1. Research the Company and Position

Familiarize yourself with the company’s mission, values, and specific requirements for the position.

- Visit the company website and review job descriptions.

- Use LinkedIn to connect with employees in the industry and gain insights.

2. Highlight Technical Expertise

Emphasize your knowledge of ordnance systems, installation procedures, and troubleshooting techniques.

- Describe specific projects or experiences that demonstrate your technical proficiency.

- Quantify your accomplishments whenever possible.

3. Demonstrate Problem-Solving Skills

Provide examples of how you have successfully diagnosed and resolved complex technical issues.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses.

- Highlight your analytical and critical thinking abilities.

4. Emphasize Safety Awareness

Stress your commitment to safety and your understanding of safety protocols.

- Describe your experience working with hazardous materials and following safety regulations.

- Mention any certifications or training you have received in safety.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ordnance Truck Installation Mechanic interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.