Are you gearing up for an interview for a Ore Bridge Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Ore Bridge Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

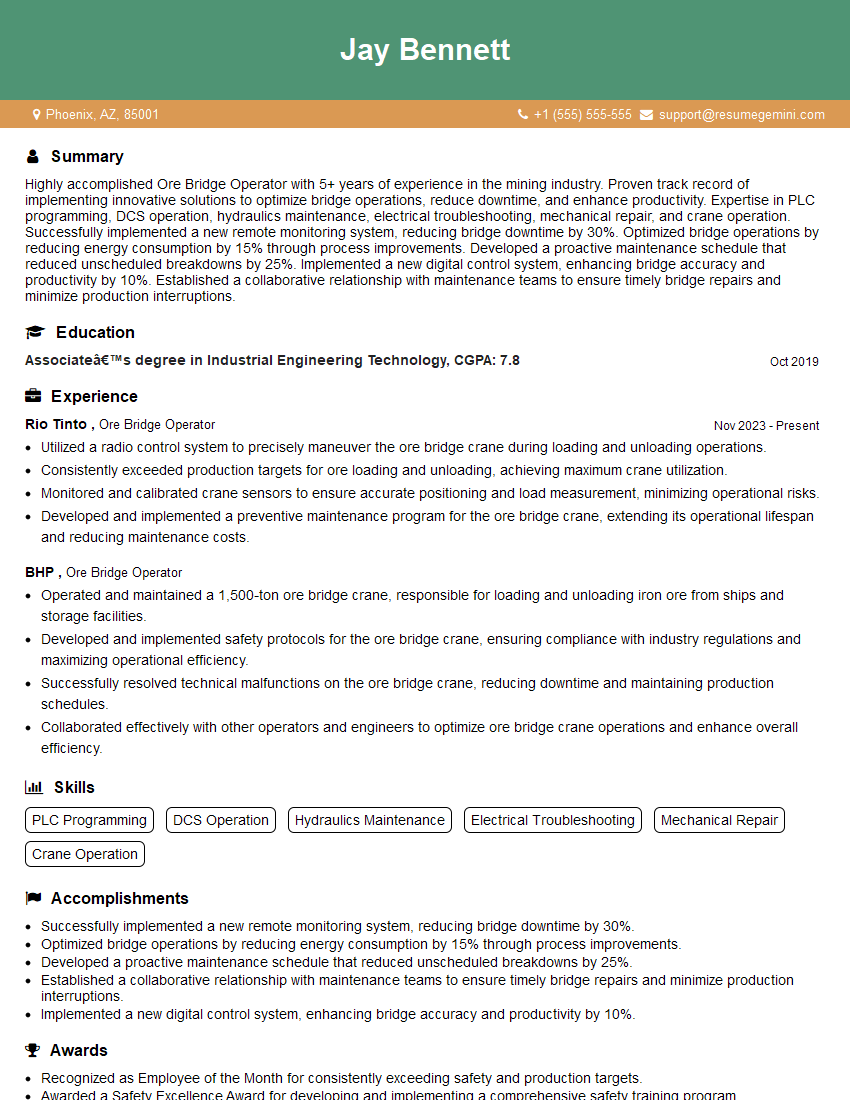

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ore Bridge Operator

1. What are the key components of an ore bridge and their functions?

Here are key components of an ore bridge:

- Bridge structure: Supports the entire weight of the bridge, including the trolley, hoist, and payload.

- Trolley: Moves back and forth along the bridge, carrying the hoist and payload.

- Hoist: Raises and lowers the payload, typically using a wire rope or chain.

- Payload: The material being transported, such as ore, coal, or other bulk materials.

- Control system: Monitors and controls the movement of the bridge, trolley, and hoist, ensuring safe and efficient operation.

- Electrical system: Provides power to the bridge and its components, including motors, lights, and sensors.

- Safety systems: Includes features such as limit switches, overload protection, and emergency stop buttons to prevent accidents and protect the operator and equipment.

2. Describe the process of loading ore onto a ship using an ore bridge.

Positioning the Bridge:

- Manuever the ore bridge over the ship’s hold.

- Adjust the bridge height and trolley position to align with the ship’s hatch.

Loading the Ore:

- Lower the hoist into the ore stockpile.

- Open the grab bucket and fill it with ore.

- Raise the hoist and move the trolley over the ship’s hold.

- Open the grab bucket and discharge the ore into the hold.

Repeating the Process:

- Repeat steps 2 and 3 until the ship’s hold is full.

- Monitor the loading process to ensure even distribution and prevent overloading.

3. What are the safety precautions that must be taken when operating an ore bridge?

Here are the safety precautions when operating an ore bridge:

- Obtain proper training and certification.

- Wear appropriate safety gear, including a hard hat, safety glasses, and high-visibility vest.

- Inspect the bridge and equipment before each use, checking for any damage or defects.

- Follow established operating procedures and load limits.

- Maintain a safe distance from other equipment and personnel.

- Be aware of potential hazards, such as overhead power lines, moving machinery, and falling objects.

- Use proper hand signals or communication devices when working with other operators.

- Report any unsafe conditions or incidents immediately.

- Stay alert and avoid distractions while operating the bridge.

4. How do you handle situations where the ore bridge encounters unexpected obstacles or malfunctions?

In case of unexpected obstacles or malfunctions:

- Remain calm and assess the situation.

- Stop the bridge operation immediately.

- Identify the obstacle or malfunction and determine its severity.

- If possible, clear the obstacle or resolve the malfunction following established procedures.

- If the obstacle or malfunction cannot be resolved, contact a supervisor or maintenance technician.

- Document the incident and report it to the appropriate authorities.

- Do not attempt to operate the bridge with known defects or malfunctions.

5. What are the maintenance procedures you follow to ensure the smooth operation of the ore bridge?

I follow these maintenance procedures:

- Regularly inspect the bridge structure, trolley, hoist, and electrical components.

- Lubricate moving parts and check for wear and tear.

- Test safety systems, such as limit switches and emergency stop buttons.

- Monitor the bridge’s performance and record any anomalies.

- Follow manufacturer’s guidelines for maintenance intervals and procedures.

- Report any maintenance issues or concerns to a supervisor or maintenance technician.

6. How do you prioritize tasks and manage your time when operating an ore bridge in a busy port environment?

I prioritize my tasks as follows:

- Ensure safety and follow established operating procedures.

- Prioritize loading and unloading operations to meet ship schedules.

- Handle urgent maintenance issues promptly.

- Coordinate with other operators and personnel to avoid conflicts and delays.

- Plan my tasks efficiently to maximize productivity.

- Use technology, such as automated systems or communication devices, to streamline operations.

7. How do you work as part of a team to ensure the efficient operation of the ore bridge?

As part of a team, I:

- Communicate effectively with other operators, supervisors, and maintenance personnel.

- Cooperate and assist other team members as needed.

- Follow instructions and contribute to the overall team goals.

- Share information and best practices to improve team performance.

- Maintain a positive and supportive work environment.

8. What is your understanding of the environmental regulations and industry standards related to ore bridge operations?

My understanding of environmental regulations and industry standards related to ore bridge operations includes:

- Minimizing dust and noise pollution.

- Preventing spills and environmental contamination.

- Complying with safety regulations and maintaining proper equipment.

- Following best practices for energy efficiency.

- Staying updated on industry standards and technological advancements.

9. How do you stay up-to-date with the latest technological advancements in ore bridge operations?

I stay up-to-date with technological advancements in ore bridge operations by:

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Participating in online forums and discussions.

- Consulting with manufacturers and technology providers.

- Seeking opportunities for training and development.

10. What are your career goals and how does this role contribute to your aspirations?

My career goal is to advance in the field of ore bridge operations and become a highly skilled and experienced operator. This role contributes to my aspirations by:

- Providing me with hands-on experience in operating and maintaining an ore bridge.

- Allowing me to develop my technical skills and knowledge.

- Offering opportunities to learn from experienced professionals.

- Helping me build a strong foundation for future career growth.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ore Bridge Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ore Bridge Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ore Bridge Operators are responsible for the safe and efficient operation of an ore bridge, a specialized piece of equipment used to load and unload bulk materials such as ore, coal, or grain. Their primary duties include:

1. Bridge Operation

Operate the ore bridge to move materials from storage areas to designated loading or unloading points, ensuring smooth and timely transfer of materials.

- Control the movement of the bridge along the runway and trolley to position it accurately over the loading or unloading area.

- Operate the bucket or grab mechanism to pick up and release materials, ensuring proper loading and unloading.

2. Equipment Maintenance

Conduct routine inspections, identify potential issues, and perform basic maintenance tasks to keep the ore bridge in good working condition.

- Inspect the bridge structure, mechanical components, electrical systems, and hydraulics for any signs of wear, damage, or leaks.

- Lubricate moving parts, replace worn components, and adjust settings as needed.

3. Safety and Compliance

Adhere to all safety regulations, operating procedures, and environmental standards to ensure the safe and efficient operation of the ore bridge.

- Wear appropriate personal protective equipment (PPE) and follow safe work practices.

- Monitor the surrounding area for potential hazards and take appropriate measures to prevent accidents.

4. Communication and Coordination

Communicate effectively with other operators, supervisors, and maintenance personnel to coordinate activities and ensure smooth operation of the ore bridge.

- Receive and relay instructions from supervisors and coordinate with other operators to ensure efficient loading and unloading.

- Report any issues or concerns to supervisors promptly to ensure timely resolution.

Interview Tips

To ace an interview for an Ore Bridge Operator position, it is essential to prepare thoroughly and demonstrate your skills and qualifications.

1. Research the Company and Position

Research the company’s history, operations, and the specific requirements of the Ore Bridge Operator role. This will help you tailor your answers and show that you are genuinely interested in the position.

2. Highlight Relevant Skills and Experience

Quantify your accomplishments and focus on transferable skills that are relevant to the job, such as operating heavy machinery, troubleshooting equipment, and ensuring safety.

3. Practice Common Interview Questions

Be prepared to answer common interview questions such as:

- Tell me about your experience operating ore bridges or similar equipment.

- How do you prioritize safety and maintain a safe work environment?

- Describe a situation where you had to troubleshoot and resolve an issue with an ore bridge.

4. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately and arrive on time for your interview. This demonstrates respect for the interviewer’s time and seriousness about the position.

5. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest in the company and the role. This shows that you are engaged and eager to learn more.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Ore Bridge Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Ore Bridge Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.