Feeling lost in a sea of interview questions? Landed that dream interview for Ore Charger but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Ore Charger interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

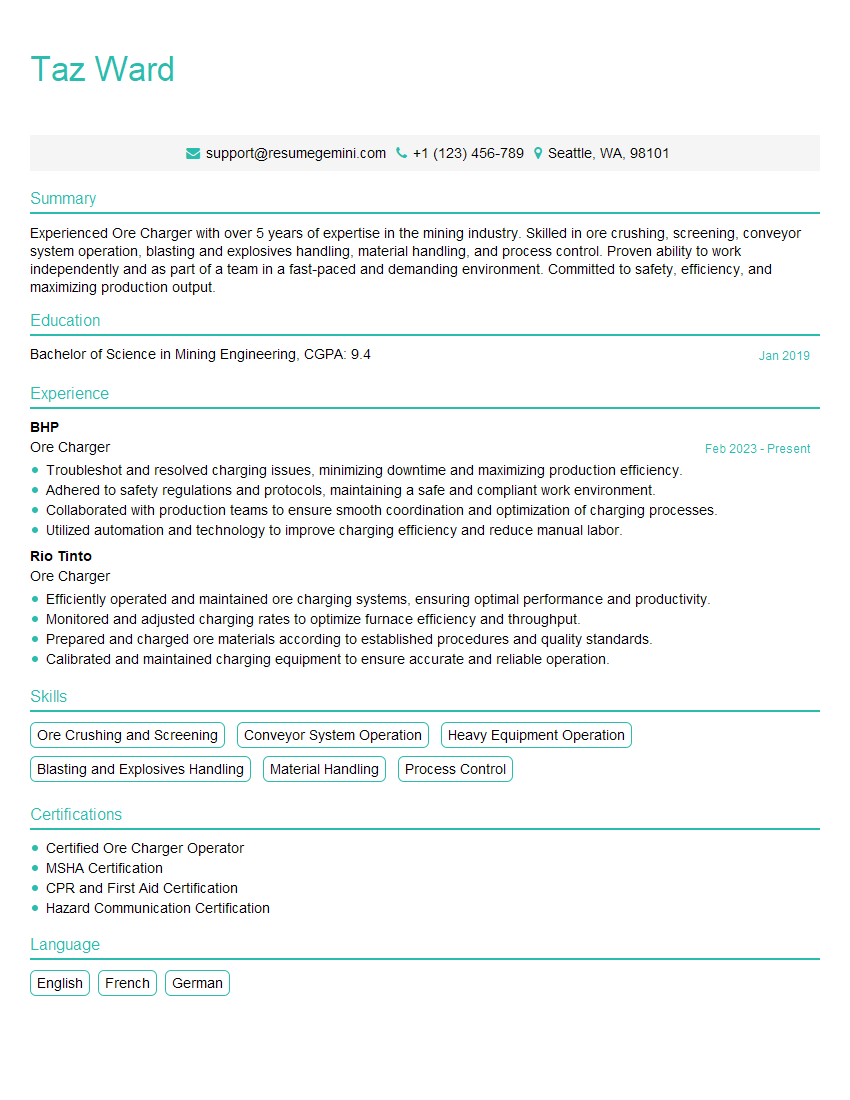

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ore Charger

1. Explain the process of charging an ore.

The process of charging an ore involves several steps:

- Crushing and grinding: The ore is first crushed and ground into smaller pieces to increase its surface area.

- Roasting: The ore is then roasted at high temperatures to remove impurities and drive off volatile components.

- Smelting: The roasted ore is mixed with a flux (usually limestone) and heated in a furnace to melt the metal-bearing minerals.

- Converting: The molten metal is then transferred to a converter, where it undergoes further oxidation and refining to remove impurities.

- Casting: The refined metal is finally cast into ingots or other desired shapes.

2. What are the different types of ore chargers?

There are two main types of ore chargers:

- Skip chargers: Skip chargers are used to charge ore and other materials into blast furnaces. They are equipped with a large bucket that is hoisted up to the top of the furnace and then tilted to discharge the contents.

- Belt chargers: Belt chargers are used to charge ore and other materials into electric arc furnaces and other types of furnaces. They consist of a conveyor belt that carries the material from a hopper to the furnace.

3. What are the key factors to consider when selecting an ore charger?

The key factors to consider when selecting an ore charger include:

- The type of furnace being charged: Different types of furnaces require different types of chargers.

- The capacity of the furnace: The capacity of the furnace will determine the size and capacity of the charger needed.

- The material being charged: The material being charged will determine the type of charger and the materials of construction required.

- The operating environment: The operating environment will determine the type of charger and the materials of construction required.

4. What are the common problems associated with ore chargers?

The common problems associated with ore chargers include:

- Mechanical failures: Mechanical failures can occur due to wear and tear, improper maintenance, or overloading.

- Electrical failures: Electrical failures can occur due to loose connections, faulty wiring, or power surges.

- Hydraulic failures: Hydraulic failures can occur due to leaks, contamination, or faulty components.

- Pneumatic failures: Pneumatic failures can occur due to leaks, contamination, or faulty components.

5. How can the problems associated with ore chargers be prevented?

The problems associated with ore chargers can be prevented by:

- Proper maintenance: Regular maintenance can help to prevent mechanical failures, electrical failures, and hydraulic failures.

- Proper operation: Following the manufacturer’s instructions for operation can help to prevent overloading and other problems.

- Regular inspections: Regular inspections can help to identify potential problems before they become major.

6. What are the latest trends in ore charger technology?

The latest trends in ore charger technology include:

- Automation: Ore chargers are becoming increasingly automated, which can help to improve safety and efficiency.

- Improved materials: Ore chargers are being made from improved materials that are more resistant to wear and tear.

- New designs: New designs are being developed to improve the efficiency and reliability of ore chargers.

7. What are the future prospects for the ore charger industry?

The future prospects for the ore charger industry are positive due to the growing demand for metals and the need for efficient and reliable ore charging equipment.

8. What are the safety considerations when operating an ore charger?

The safety considerations when operating an ore charger include:

- Wearing proper personal protective equipment (PPE)

- Following the manufacturer’s instructions for operation

- Being aware of the surroundings

- Avoiding contact with moving parts

9. What are the environmental considerations when operating an ore charger?

The environmental considerations when operating an ore charger include:

- Minimizing dust emissions

- Preventing spills

- Following proper waste disposal procedures

10. What are the training requirements for ore charger operators?

The training requirements for ore charger operators include:

- Formal training from the manufacturer

- On-the-job training under the supervision of an experienced operator

- Regular refresher training

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ore Charger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ore Charger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ore Chargers, also known as Blast Furnace Chargers, play a crucial role in the iron and steel industry. Their primary responsibility is to charge materials into blast furnaces, ensuring a continuous and efficient production process. Here are some key job responsibilities of an Ore Charger:

1. Raw Material Handling

Ore Chargers are responsible for handling and charging raw materials into the blast furnace. This includes ore, coke, and limestone, which are essential components for iron production.

- Operate charging equipment, such as skips and conveyor belts, to load and transport raw materials.

- Ensure that the raw materials are properly weighed, sized, and distributed within the blast furnace.

2. Monitoring Furnace Operations

Ore Chargers closely monitor the operations of the blast furnace to maintain optimal conditions for iron production. They observe and record various parameters, and make necessary adjustments to ensure efficient and safe operations.

- Monitor furnace temperature, pressure, and gas flow to ensure optimal conditions for iron production.

- Observe and record slag and iron levels in the furnace to adjust the charging rate and maintain proper furnace operation.

3. Equipment Maintenance

Ore Chargers are responsible for the maintenance and upkeep of charging equipment. They perform regular inspections, lubrications, and repairs to ensure that the equipment is operating smoothly and efficiently.

- Perform routine maintenance and repairs on charging equipment, such as skips, conveyors, and hoists.

- Inspect and maintain electrical and mechanical systems associated with charging operations.

4. Safety and Compliance

Safety is paramount in the iron and steel industry. Ore Chargers are responsible for adhering to safety regulations and procedures to minimize risks and protect themselves and others.

- Follow all safety protocols and guidelines, including wearing appropriate protective gear.

- Identify and assess potential hazards associated with charging operations and take appropriate measures to mitigate risks.

Interview Tips

Preparing for an Ore Charger interview requires a combination of technical knowledge and an understanding of the industry. Here are some tips and hacks to help you ace the interview:

1. Research the Industry and Company

Familiarize yourself with the iron and steel industry, including the role of Ore Chargers in the production process. Research the specific company you are applying to, their operations, and their safety practices.

- Visit the company’s website to learn about their history, products, and culture.

- Read industry publications and news articles to stay updated on advancements in iron and steel production.

2. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and knowledge of the industry. Some typical questions include:

- Tell us about your experience in handling and charging raw materials in a blast furnace.

- Describe your understanding of the safety protocols and procedures involved in blast furnace charging operations.

- How do you monitor and maintain optimal conditions for iron production in a blast furnace?

3. Highlight Your Technical Skills

Emphasize your technical skills and knowledge related to blast furnace charging. This may include experience in operating charging equipment, monitoring furnace operations, and performing equipment maintenance.

- Provide specific examples of how you have used your skills to improve efficiency or safety in a blast furnace operation.

- Discuss your understanding of the different types of raw materials used in iron production and their impact on furnace performance.

4. Showcase Your Safety Awareness

Safety is a crucial aspect of Ore Charger responsibilities. Demonstrate your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Describe your experience in identifying and mitigating potential hazards in a blast furnace operation.

- Explain how you ensure that your actions comply with all applicable safety regulations and company policies.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ore Charger interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.