Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ore Dressing Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

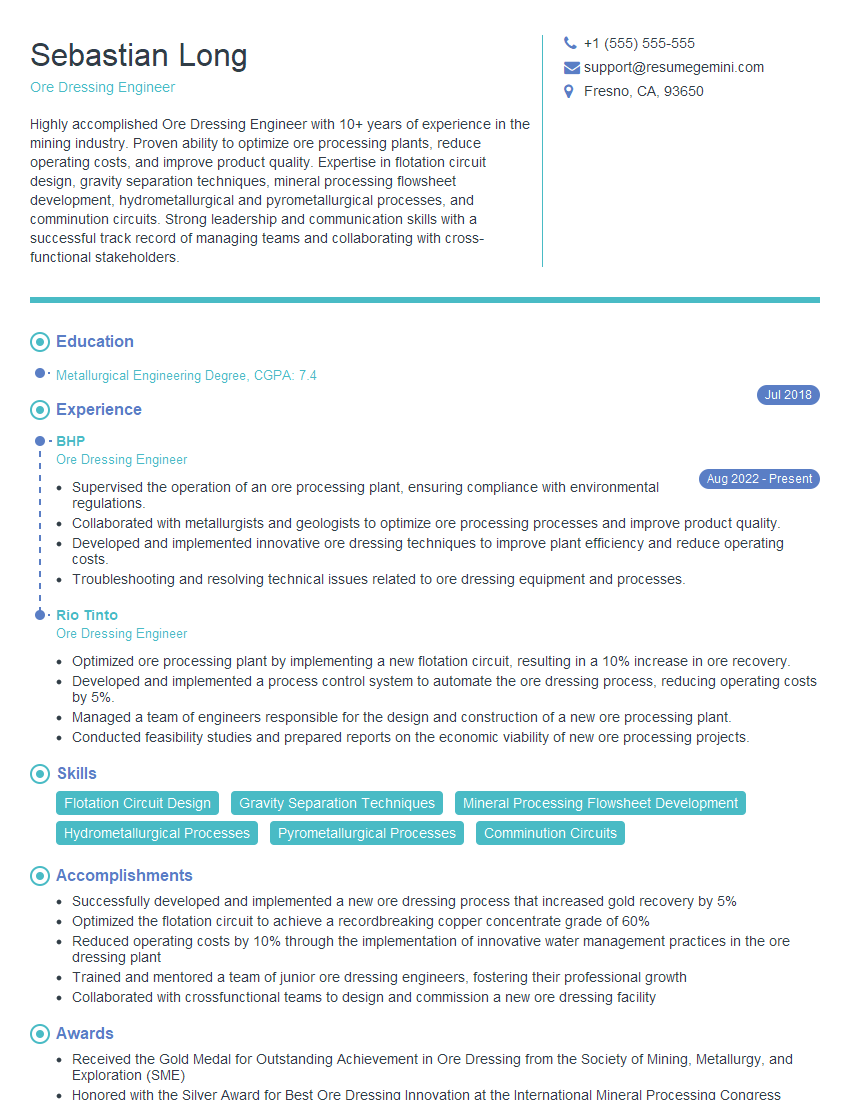

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ore Dressing Engineer

1. What are the key steps involved in the ore dressing process?

The key steps involved in the ore dressing process are:

- Crushing and grinding: Breaking down the ore into smaller pieces to liberate the valuable minerals.

- Beneficiation: Separating the valuable minerals from the waste rock or gangue minerals using various techniques such as gravity separation, flotation, or magnetic separation.

- Thickening and filtration: Concentrating the valuable minerals by removing excess water or other liquids.

- Drying: Removing moisture from the concentrated minerals to prepare them for further processing.

2. Describe the different types of crushers used in ore dressing.

Jaw crusher

- Uses two jaws to crush the ore.

- Suitable for primary crushing of hard and abrasive ores.

Gyratory crusher

- Uses a cone-shaped head to crush the ore.

- Suitable for secondary and tertiary crushing of medium to fine ores.

Impact crusher

- Uses high-speed impact to break down the ore.

- Suitable for crushing soft and brittle ores.

3. How does gravity separation work in ore dressing?

Gravity separation is a technique used to separate minerals based on their different specific gravities.

- The ore is fed into a fluid (usually water) and allowed to settle.

- Heavier minerals with higher specific gravities sink faster than lighter minerals.

- The different minerals can then be separated by collecting them at different levels of the fluid column.

4. What is flotation and how is it used in ore dressing?

Flotation is a technique used to separate minerals based on their different surface properties.

- The ore is mixed with water and a flotation reagent, which is a chemical that alters the surface properties of the minerals.

- Air is introduced into the mixture, causing bubbles to form.

- Hydrophobic (water-repelling) minerals attach themselves to the bubbles and rise to the surface, while hydrophilic (water-loving) minerals remain in the water.

- The froth containing the hydrophobic minerals is collected and the remaining water is discarded.

5. Describe the role of magnetic separation in ore dressing.

Magnetic separation is a technique used to separate minerals based on their magnetic properties.

- The ore is passed through a magnetic field.

- Magnetic minerals are attracted to the field and separated from non-magnetic minerals.

- This technique is commonly used to separate iron ores from other minerals.

6. What are the factors that affect the efficiency of ore dressing operations?

- Ore characteristics (mineralogy, grain size, liberation)

- Process parameters (crushing size, flow rate, reagent dosage)

- Equipment performance (crusher type, separator design)

- Operator skill and experience

- Environmental conditions (temperature, humidity)

7. What are the challenges and trends in the ore dressing industry?

Challenges

- Processing complex and low-grade ores

- Meeting environmental regulations

- Improving efficiency and reducing costs

Trends

- Development of new and innovative technologies

- Use of automation and data analytics

- Focus on sustainability and environmental stewardship

8. Describe a specific project where you successfully implemented an ore dressing solution.

In my previous role at [Company Name], I was involved in a project to optimize the ore dressing process for a copper mine.

- I conducted a detailed analysis of the ore characteristics and the existing process.

- I recommended modifications to the crushing and grinding circuits to improve liberation.

- I optimized the flotation process by adjusting reagent dosage and operating parameters.

- As a result of these changes, the copper concentrate grade increased by 5% and the recovery rate improved by 3%, leading to a significant increase in profitability.

9. How do you stay up-to-date with the latest advancements in ore dressing technology?

- Attending industry conferences and workshops

- Reading technical journals and research papers

- Networking with other professionals in the field

- Participating in professional development courses and certifications

10. What are your strengths and weaknesses as an Ore Dressing Engineer?

Strengths

- Strong understanding of ore dressing principles and technologies

- Experience in various ore dressing operations

- Proven ability to optimize processes and improve efficiency

- Excellent problem-solving and analytical skills

Weaknesses

- Limited experience with certain advanced technologies

- Not yet fluent in a second language

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ore Dressing Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ore Dressing Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ore Dressing Engineers perform a crucial role in the mining industry by designing and implementing processes to extract valuable minerals from ore.1. Ore Characterization and Analysis

Conduct thorough analysis of ore samples to determine their physical and chemical properties, including particle size distribution, mineralogy, and liberation characteristics.

- Design and conduct laboratory tests to evaluate ore properties and identify the most suitable extraction methods.

- Use advanced analytical techniques, such as X-ray diffraction, to determine the mineralogical composition of ore samples.

2. Process Design and Optimization

Develop and optimize ore dressing processes to maximize mineral recovery while minimizing waste and environmental impact.

- Design and specify equipment for ore crushing, grinding, screening, and beneficiation processes.

- Use mathematical models and simulation software to optimize process parameters, such as feed rates, particle sizes, and reagent dosages.

3. Plant Operation and Management

Supervise and manage ore dressing plants to ensure efficient operation, safety, and environmental compliance.

- Monitor and adjust process parameters to maintain optimal performance and meet production targets.

- Identify and troubleshoot operational problems, implementing corrective actions to minimize downtime and maximize plant efficiency.

4. Research and Development

Conduct research and development activities to improve ore dressing processes and develop new technologies.

- Investigate innovative methods to improve mineral recovery, reduce energy consumption, and enhance environmental sustainability.

- Stay abreast of advances in ore dressing technology and apply the latest knowledge to optimize plant operations.

Interview Tips

By understanding the key job responsibilities of an Ore Dressing Engineer and following these interview tips, you can increase your chances of making a great impression and landing the job.

1. Research the Company and the Industry

Take the time to learn about the company you’re applying to and the industry in which they operate.

- Visit the company’s website, read industry news, and attend relevant conferences.

- This will help you understand the company’s culture, values, and strategic goals.

2. Practice Your Technical Skills

Ore Dressing Engineers need to have a strong foundation in technical skills such as process design, optimization, and analysis.

- Review your coursework and practice solving problems related to ore characterization, process simulation, and plant operation.

- Consider working on personal projects or contributing to open-source software to demonstrate your abilities.

3. Highlight Your Problem-Solving Abilities

The ability to solve problems is critical for Ore Dressing Engineers.

- During the interview, provide specific examples of how you have identified and solved problems in previous roles or projects.

- Explain your thought process and the steps you took to arrive at solutions.

4. Demonstrate Your Communication Skills

Ore Dressing Engineers need to be able to communicate effectively with both technical and non-technical audiences.

- Practice presenting your technical findings clearly and concisely.

- Be prepared to answer questions and explain complex concepts in a way that is easy to understand.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ore Dressing Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!