Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Ore Mixer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Ore Mixer so you can tailor your answers to impress potential employers.

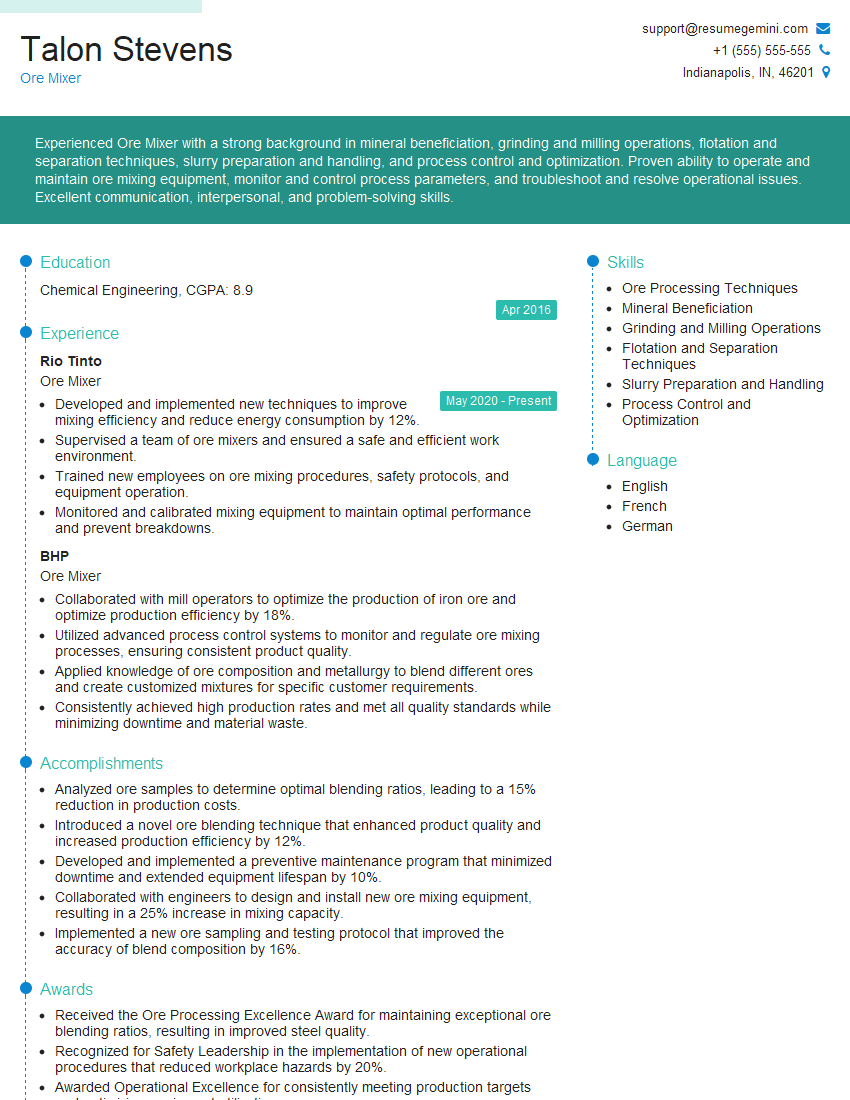

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ore Mixer

1. Describe the primary responsibilities of an Ore Mixer.

As an Ore Mixer, my key responsibilities involve:

- Blending and mixing various types of ores and additives to create a uniform feed for the smelting or refining process

- Ensuring accurate proportions and consistent quality of the mixed materials

- Operating and maintaining mixing equipment, including conveyors, crushers, and mixers

- Monitoring and adjusting process parameters to optimize mixing efficiency

- Inspecting mixed materials for quality control

2. Explain the importance of blending different ores in a mixing process.

Benefits of Blending:

- Improves overall ore quality by creating a homogeneous blend

- Reduces fluctuations in ore composition, ensuring consistent feed for downstream processes

- Enhances extraction efficiency and reduces smelting or refining costs

- Maximizes resource utilization by blending lower-grade ores with higher-grade materials

- Allows for the addition of additives or fluxing agents to optimize metallurgical processes

3. Discuss the factors that influence the choice of mixing equipment.

The selection of mixing equipment depends on various factors, including:

- Volume and type of ores to be mixed

- Required level of homogeneity

- Mixing efficiency and energy consumption

- Equipment availability, cost, and maintenance requirements

- Safety and environmental considerations

4. Describe the role of sampling and testing in the ore mixing process.

Sampling and testing play a crucial role in ensuring the quality and consistency of mixed ores:

- Representative samples are taken at regular intervals to determine ore composition

- Samples are analyzed using various techniques, such as X-ray fluorescence (XRF) or atomic absorption spectroscopy (AAS)

- Test results are compared to specifications and used to adjust mixing parameters and ensure uniformity

- Continuous monitoring and testing allow for timely detection and correction of any deviations from desired quality

5. Explain the safety precautions necessary when working with ores and mixing equipment.

Safety remains paramount when handling ores and operating mixing equipment:

- Proper personal protective equipment (PPE) is worn, including safety glasses, gloves, and respirators

- Adequate ventilation is maintained to prevent inhalation of dust and fumes

- Regular inspections and maintenance of equipment are conducted to ensure it is in good working order

- Lockout/tagout procedures are followed during maintenance or repairs

- Emergency response plans are in place and all employees are trained on appropriate actions

6. Describe any previous experience you have with troubleshooting and resolving issues in an ore mixing operation.

In my previous role at [Company Name], I successfully diagnosed and resolved the following issues:

- Identified and corrected a faulty sensor that led to inaccurate mixing proportions

- Troubleshooted a mechanical failure in the conveyor system, ensuring uninterrupted ore supply

- Resolved a quality issue by adjusting the mixing time and sequence to improve ore homogeneity

- Collaborated with maintenance personnel to optimize equipment performance and minimize downtime

7. Explain how you stay updated with advancements and best practices in ore mixing technology.

I maintain my knowledge and skills through the following methods:

- Attending industry conferences and workshops

- Reading technical journals and research papers

- Participating in professional organizations and networking with industry experts

- Seeking opportunities for continuous learning and development

- Consulting with equipment manufacturers and technology providers

8. Discuss the challenges you anticipate in the role of an Ore Mixer and how you would overcome them.

Potential challenges and my approach to overcoming them:

- Ensuring consistent product quality: By implementing rigorous sampling and testing protocols, optimizing mixing parameters, and maintaining equipment in top condition

- Meeting production targets: By streamlining processes, improving equipment efficiency, and working closely with downstream operations

- Minimizing downtime: Through preventive maintenance, rapid troubleshooting, and collaboration with maintenance teams

- Adapting to changing ore characteristics: By adjusting mixing parameters based on test results, experimenting with new techniques, and seeking guidance from industry experts

9. Describe your approach to working effectively in a team environment.

I am a highly collaborative and team-oriented individual who values open communication:

- I actively participate in team discussions and share my knowledge and experience

- I am always willing to lend a hand and support colleagues

- I am receptive to feedback and suggestions, and I strive to contribute to the team’s success

- I am proficient in using communication tools and technologies to stay connected and share information

10. How would you prioritize your workload and manage multiple projects simultaneously?

I utilize the following strategies to prioritize my workload and manage multiple projects:

- Establish clear priorities: I prioritize tasks based on urgency, importance, and deadlines

- Create a structured schedule: I break down projects into smaller tasks and allocate time for each

- Delegate and collaborate: I delegate tasks to others when appropriate and collaborate with team members to share the workload

- Use project management tools: I leverage tools such as Gantt charts and task lists to track progress and stay organized

- Regularly review and adjust: I periodically review my progress and make adjustments to my schedule as needed

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ore Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ore Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ore mixers play a crucial role in the iron and steel production process. Their responsibilities encompass all aspects of mixing and preparing raw materials for blast furnaces.

1. Raw Material Preparation

Ore mixers are responsible for receiving, storing, and preparing raw materials used in the iron-making process. These materials include iron ore, coke, limestone, and other additives.

- Unload incoming raw materials from trucks or trains.

- Store and maintain raw materials in designated areas.

- Control the quality of raw materials by conducting regular sampling and analysis.

- Prepare and blend raw materials to meet specific mix ratios and ensure consistency.

2. Mixing and Proportioning

Ore mixers use specialized equipment to mix and proportion raw materials accurately. They ensure that the mixture meets the required chemical composition and physical properties for optimal blast furnace performance.

- Operate mixing and proportioning equipment to create desired raw material blends.

- Monitor and adjust blend ratios to maintain consistent quality.

- Control the flow of materials through mixing and conveying systems.

- Troubleshoot mechanical issues with mixing and proportioning equipment.

3. System Maintenance and Operation

Ore mixers are responsible for maintaining and operating the mixing and conveying systems used in the raw material preparation process. They ensure that equipment is running efficiently and safely.

- Conduct regular maintenance and inspections of mixing and conveying systems.

- Troubleshoot and repair equipment malfunctions.

- Follow established safety procedures and regulations.

- Maintain a clean and organized work area.

4. Quality Control and Monitoring

Ore mixers are responsible for monitoring the quality of raw materials and ensuring that the mixing process meets specified standards. They conduct regular tests and inspections to maintain consistent product quality.

- Monitor raw material quality through testing and analysis.

- Ensure that the mixing process adheres to established quality control standards.

- Investigate and resolve any issues related to raw material quality or mixing performance.

- Provide feedback on raw material quality and mixing process efficiency to improve operations.

Interview Tips

Preparing for an interview for an Ore Mixer position requires a combination of research, practice, and confidence. Here are some tips to help you ace the interview:

1. Know the Job Description

Thoroughly review the job description and make a list of the key responsibilities and qualifications required for the role. This will help you understand the expectations of the position and tailor your answers accordingly.

- Research the company and the industry to gain insights into their operations and culture.

- Identify your skills and experience that match the job requirements and highlight them in your resume and interview.

2. Practice Your Answers

Preparing well for common interview questions can help you deliver confident and informed answers. Practice answering questions related to your experience in raw material preparation, mixing and proportioning, system maintenance and operation, and quality control.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

3. Be Enthusiastic and Professional

During the interview, it is important to convey your enthusiasm for the role and your commitment to the industry. Maintain a positive and professional demeanor, and dress appropriately for the occasion.

- Show your passion for raw material preparation and the iron-making process.

- Ask thoughtful questions to demonstrate your interest in the position and the company.

4. Follow Up and Stay Positive

After the interview, send a thank-you note to the interviewer within 24 hours. Express your appreciation for the opportunity to interview and reiterate your interest in the position. Stay positive and confident, even if you do not receive an offer immediately.

- Use the opportunity to highlight any additional qualifications or experiences that you may have forgotten to mention during the interview.

- Follow up periodically if you have not heard back within the specified timeframe.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Ore Mixer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Ore Mixer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.