Are you gearing up for a career in Ornamental Iron Worker Apprentice? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Ornamental Iron Worker Apprentice and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

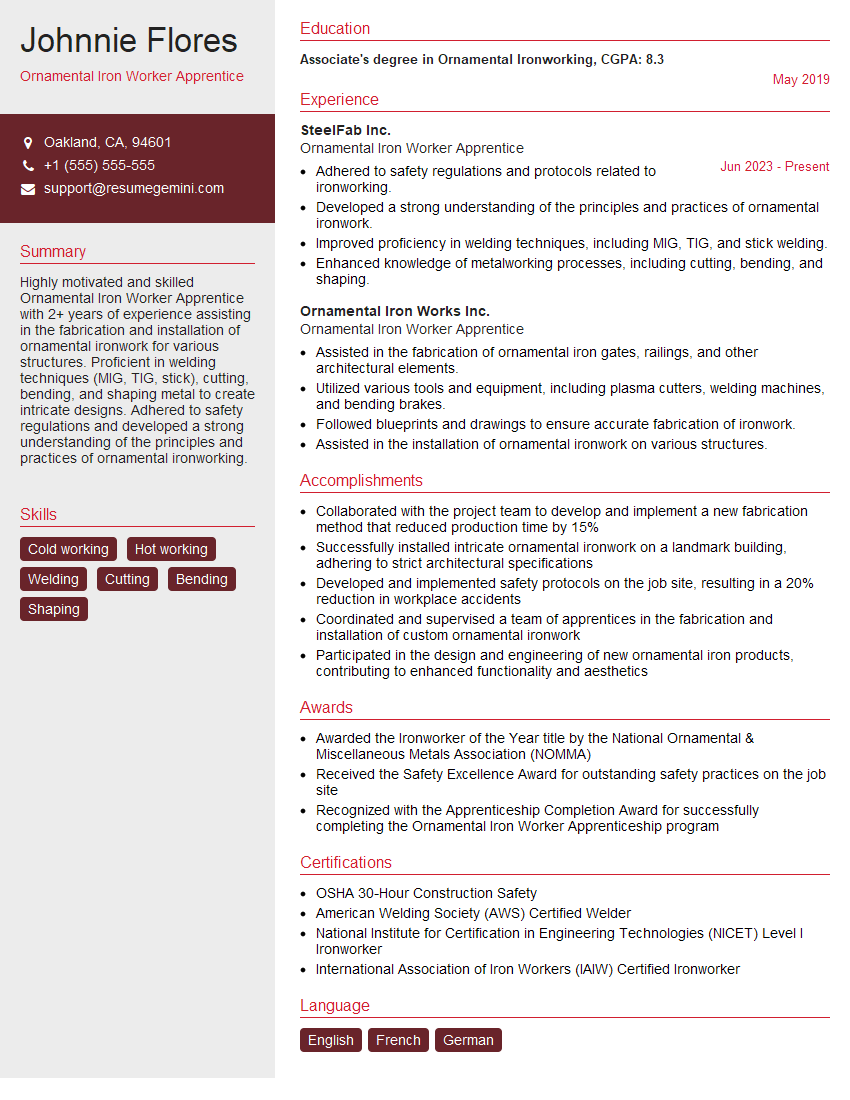

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ornamental Iron Worker Apprentice

1. Explain the process of fabricating and installing ornamental iron railings.

The process of fabricating and installing ornamental iron railings involves several key steps:

- Design and Engineering: The design of the railing is created by an engineer or architect, taking into account specifications, codes, and aesthetic considerations.

- Material Selection: The appropriate type of iron is selected based on factors such as strength, durability, and aesthetic appeal.

- Fabrication: The iron is cut, shaped, and welded together in accordance with the design plans.

- Finishing: The railings are finished with coatings or treatments to protect against corrosion and enhance their appearance.

- Installation: The railings are installed on-site by skilled ironworkers, ensuring proper fit, alignment, and safety.

2. Describe the different types of welding techniques used in ornamental iron work.

Electric Arc Welding

- MIG (Metal Inert Gas): Uses an inert gas to shield the weld area, producing clean and precise welds.

- TIG (Tungsten Inert Gas): Employs a tungsten electrode and an inert gas to create high-quality welds with minimal spatter.

Gas Welding

- Oxy-acetylene Welding: Uses a combination of oxygen and acetylene gases to create a hot flame for welding.

- Brazing: Joins metal by melting a lower-melting point filler metal that bonds to the base metal.

3. What are the safety precautions that must be taken when working with ornamental iron?

Working with ornamental iron requires adherence to strict safety precautions to minimize risks:

- Protective Gear: Wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and respirators.

- Safe Handling: Using proper lifting techniques to avoid injuries and handling sharp edges with care.

- Welding Safety: Ensuring proper ventilation, using welding screens, and wearing flame-resistant clothing.

- Fall Prevention: Working at heights requires the use of fall protection equipment like harnesses and lifelines.

- Hazard Identification: Being aware of potential hazards in the work area and taking steps to mitigate them.

4. Explain the techniques used for bending and shaping ornamental iron.

Bending and shaping ornamental iron involves various techniques to achieve the desired curvature and form:

- Cold Bending: Using a press brake or bender to apply force and bend the iron at room temperature.

- Hot Bending: Heating the iron to a high temperature to make it more malleable and easier to bend.

- Hammering and Forging: Using hammers and anvils to manually shape and contour the iron.

- Rolling: Passing the iron through a rolling mill to reduce its thickness and create curved profiles.

5. How do you ensure that ornamental iron railings meet the required standards and codes?

Meeting standards and codes in ornamental ironwork is crucial for safety and quality:

- Design Compliance: Adhering to industry standards and building codes for load-bearing capacity, dimensions, and materials.

- Material Specifications: Using iron that meets the required strength and durability specifications.

- Fabrication Quality: Ensuring that the railings are fabricated with precision and accuracy.

- Inspection and Testing: Conducting thorough inspections and load testing to verify compliance with standards.

- Documentation: Maintaining proper documentation to show that the railings meet the specified requirements.

6. What are the different types of ornamental iron finishes and their characteristics?

- Paint: Provides color and protection; available in various textures and sheen levels.

- Powder Coating: A durable and corrosion-resistant finish applied through electrostatic spray.

- Galvanizing: A process that coats the iron with zinc to protect against rust and corrosion.

- Anodic Oxidation: An electrochemical process that forms a protective and decorative oxide layer on the surface.

- Patina: A natural aging process that creates a unique and protective layer on the iron’s surface.

7. Describe the importance of proper storage and handling of ornamental iron materials to prevent damage.

Proper storage and handling are essential to prevent damage to ornamental iron materials:

- Dry Storage: Storing iron in a dry environment to avoid rust and corrosion.

- Protecting Surfaces: Covering iron surfaces with protective materials to prevent scratches and dents.

- Careful Handling: Using proper lifting techniques and avoiding rough handling to minimize damage.

- Inventory Management: Tracking inventory and ensuring proper rotation to prevent long-term storage issues.

8. How do you handle complex ornamental iron designs that require intricate detailing and precision?

Handling complex designs in ornamental ironwork involves skilled craftsmanship and attention to detail:

- Design Analysis: Thoroughly studying the design to understand its complexity and identify potential challenges.

- Template Creation: Creating detailed templates to guide the fabrication process and ensure accuracy.

- Precision Cutting and Shaping: Using specialized tools and techniques to cut and shape the iron with precision.

- Welding Techniques: Employing appropriate welding techniques to join pieces together seamlessly and maintain structural integrity.

- Finishing Touches: Paying attention to detail during finishing and assembly to ensure the final product meets the design specifications.

9. What are the common problems encountered in ornamental iron fabrication and how do you resolve them?

Common problems in ornamental iron fabrication and their resolutions:

- Warpage: Controlled cooling and proper welding techniques to minimize distortion.

- Weld Defects: Inspecting welds for proper penetration and using appropriate welding parameters.

- Surface Imperfections: Grinding and polishing to remove scratches, dents, or other surface defects.

- Dimensional Errors: Careful measuring and template creation to ensure accurate sizing and alignment.

- Rust and Corrosion: Proper material selection, surface preparation, and protective finishes to prevent corrosion.

10. How do you stay updated with the latest advancements and trends in ornamental ironwork?

- Industry Events: Attending trade shows and workshops to network and learn about new products and techniques.

- Professional Development: Reading industry publications, taking online courses, or participating in apprenticeships to enhance skills.

- Collaboration: Exchanging knowledge and experiences with other ironworkers and artisans.

- Online Resources: Utilizing online forums, websites, and social media platforms to stay informed.

- Research and Development: Exploring new materials, processes, and technologies to improve efficiency and quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ornamental Iron Worker Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ornamental Iron Worker Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ornamental Iron Worker Apprentices perform a variety of tasks to assist journey-level ironworkers in the fabrication, installation, and repair of ornamental ironwork. These responsibilities may include:

1. Material Handling

Assist with the unloading, loading, and movement of materials, such as steel beams, bars, and sheets.

2. Fabrication

Help fabricate ornamental ironwork components, such as railings, gates, and fences, using tools like welding machines, grinders, and bending brakes.

3. Installation

Assist with the installation of ornamental ironwork components, including securing them to structures and ensuring proper alignment and fit.

4. Repair

Help repair ornamental ironwork components, such as straightening bent bars or replacing damaged sections.

5. Maintenance

Help maintain ornamental ironwork components by cleaning and protecting them from corrosion and other damage.

6. Safety

Follow safety protocols and wear appropriate personal protective equipment (PPE) while working with ironwork and machinery.

7. Teamwork

Work as part of a team to complete projects efficiently and effectively.

8. Communication

Communicate effectively with journey-level ironworkers and other team members to ensure clear understanding of instructions and project requirements.

Interview Tips

Preparing for an interview for an Ornamental Iron Worker Apprenticeship can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Learn about the company’s history, values, and the industry in which they operate. This will help you understand the company’s culture and the role of an Ornamental Iron Worker Apprentice within their organization.

2. Practice Your Answers to Common Interview Questions

Prepare answers to common interview questions, such as “Why are you interested in this apprenticeship?” and “What are your strengths and weaknesses?”. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

3. Highlight Your Experience and Skills

Emphasize your relevant experience and skills, even if they are not directly related to ornamental ironwork. For example, if you have experience in construction, metalworking, or welding, mention it and explain how it has prepared you for an apprenticeship in this field.

4. Demonstrate Your Safety Awareness

Ornamental ironwork involves working with heavy materials and machinery, so it’s essential to demonstrate your safety awareness during the interview. Mention any safety training or certifications you have, and emphasize your commitment to working safely.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the opportunity. Prepare a few questions that demonstrate your enthusiasm for the apprenticeship and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ornamental Iron Worker Apprentice interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.