Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ornamental Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

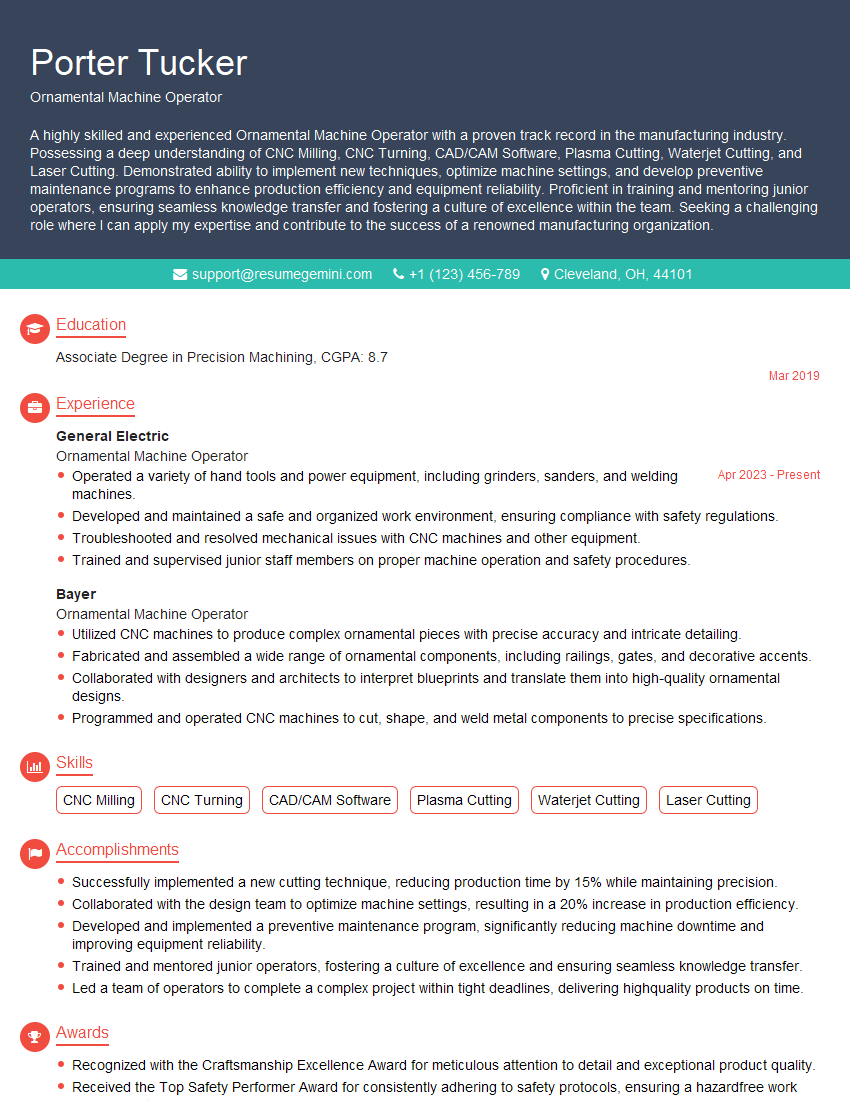

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ornamental Machine Operator

1. What is the purpose of using a coolant in ornamental machine operation?

The purpose of using a coolant in ornamental machine operation is to:

- Reduce friction between the cutting tool and the workpiece, which can help to extend the life of the tool.

- Cool the workpiece and the cutting tool, which can help to prevent thermal damage to the workpiece and the tool.

- Lubricate the cutting tool and the workpiece, which can help to reduce wear and tear on the tool and the workpiece.

- Flush away chips and other debris from the cutting area, which can help to prevent the buildup of material on the tool and the workpiece.

2. What are the different types of ornamental machine tools?

CNC Machines

- Computer Numerical Control (CNC) machines are automated machines that are controlled by a computer program.

- CNC machines are used to create a wide variety of ornamental products, such as moldings, carvings, and plaques.

Manual Machines

- Manual machines are operated by hand, and they require the operator to have a high level of skill and experience.

- Manual machines are often used to create one-of-a-kind pieces or to make small batches of products.

3. What are the different types of materials that can be used in ornamental machine operation?

The different types of materials that can be used in ornamental machine operation include:

- Wood

- Metal

- Plastic

- Glass

- Stone

4. What are the different types of finishes that can be applied to ornamental machine products?

The different types of finishes that can be applied to ornamental machine products include:

- Paint

- Stain

- Lacquer

- Varnish

- Wax

5. What are the safety precautions that must be taken when operating an ornamental machine?

The safety precautions that must be taken when operating an ornamental machine include:

- Always wear appropriate safety gear, such as safety glasses, gloves, and a dust mask.

- Never operate a machine that is not properly guarded.

- Be aware of the location of all controls and emergency stop buttons.

- Never reach into the cutting area of a machine while it is running.

- Always disconnect the machine from power before performing any maintenance or repairs.

6. What are the most common problems that can occur when operating an ornamental machine?

The most common problems that can occur when operating an ornamental machine include:

- The machine may not be properly calibrated, which can result in inaccurate cuts.

- The cutting tool may be dull or damaged, which can result in poor quality cuts.

- The workpiece may not be properly secured, which can result in the workpiece being damaged or the machine being damaged.

- The machine may overheat, which can result in the machine being damaged or the workpiece being damaged.

7. How can the quality of ornamental machine products be improved?

The quality of ornamental machine products can be improved by:

- Using high-quality materials.

- Using sharp cutting tools.

- Properly calibrating the machine.

- Properly securing the workpiece.

- Following the manufacturer’s instructions for operating the machine.

8. What are the latest trends in ornamental machine technology?

The latest trends in ornamental machine technology include:

- The use of CNC machines to create more complex and intricate designs.

- The use of new materials, such as plastics and composites, to create lighter and more durable products.

- The use of new finishing techniques, such as laser engraving and waterjet cutting, to create more unique and visually appealing products.

9. What are the career opportunities for ornamental machine operators?

Ornamental machine operators can find work in a variety of industries, including:

- Furniture making

- Architectural woodworking

- Sign making

- Product design

- Education

10. What are the educational requirements for ornamental machine operators?

Ornamental machine operators typically need a high school diploma or equivalent. Some employers may require applicants to have a certificate or degree in ornamental machine operation. Many ornamental machine operators learn their skills through on-the-job training.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ornamental Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ornamental Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ornamental Machine Operators are responsible for operating machines that create ornamental designs on metal, wood, or other materials. They use a variety of tools and techniques to create intricate patterns and shapes. Key job responsibilities include:

1. Setting up and operating machines

Ornamental Machine Operators must be able to set up and operate a variety of machines, including lathes, mills, and grinders. They must also be able to adjust the machines to create the desired patterns and shapes.

- Set up and operate machines according to established specifications and procedures.

- Inspect and maintain machines to ensure proper functioning.

2. Creating ornamental designs

Ornamental Machine Operators use a variety of tools and techniques to create ornamental designs. These designs can be simple or complex, and they can be used to decorate a variety of products, including furniture, jewelry, and architecture.

- Create ornamental designs using a variety of tools and techniques.

- Follow blueprints and drawings to create accurate designs.

3. Inspecting and testing products

Ornamental Machine Operators must inspect and test products to ensure that they meet quality standards. They also must be able to identify and correct any defects.

- Inspect and test products to ensure they meet specifications.

- Identify and correct defects in products.

4. Maintaining a clean and safe work area

Ornamental Machine Operators must maintain a clean and safe work area. They must also be able to follow safety procedures and regulations.

- Maintain a clean and safe work area.

- Follow safety procedures and regulations.

Interview Tips

Preparing for an interview for an Ornamental Machine Operator position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. It will also help you to prepare thoughtful questions to ask the interviewer.

- Visit the company’s website to learn about their history, products, and services.

- Read industry news and articles to stay up-to-date on the latest trends.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Think about your experiences and skills and how they relate to the job you are applying for.

- Prepare specific examples that demonstrate your abilities.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the job and that you respect their time.

- Choose clothing that is clean, pressed, and appropriate for the office environment.

- Arrive for your interview 5-10 minutes early to give yourself time to relax and prepare.

4. Be yourself and be confident

The most important thing is to be yourself and be confident in your abilities. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest and authentic in your answers.

- Make eye contact and speak clearly and confidently.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Ornamental Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.