Feeling lost in a sea of interview questions? Landed that dream interview for Ornamental Metal Erector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Ornamental Metal Erector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

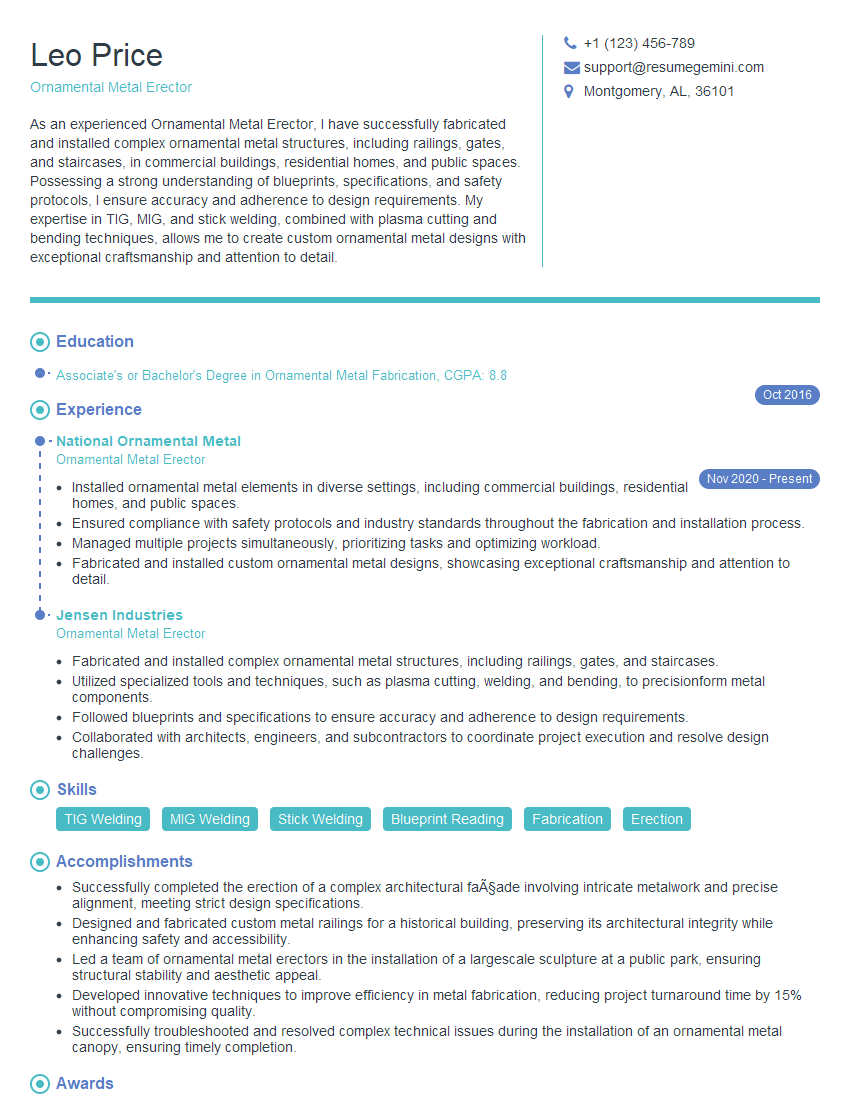

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ornamental Metal Erector

1. What are the different types of welding joints used in ornamental metal fabrication?

There are various types of welding joints used in ornamental metal fabrication, including:

- Butt joint: Used to join two pieces of metal end-to-end.

- Edge joint: Used to join two pieces of metal side-by-side along their edges.

- T-joint: Used to join a piece of metal perpendicularly to another piece.

- Corner joint: Used to join two pieces of metal at a 90-degree angle.

- Lap joint: Used to join two pieces of metal by overlapping them.

2. How do you calculate the appropriate size and thickness of the metal for an ornamental metal project?

Material Strength

- Tensile strength: Resistance to pulling forces.

- Yield strength: Resistance to permanent deformation.

Load Analysis

- Dead loads: Constant forces, e.g., weight of the structure.

- Live loads: Temporary or variable forces, e.g., wind, snow.

Design Codes and Standards

- American Institute of Steel Construction (AISC)

- International Building Code (IBC)

3. What are some of the common challenges faced in ornamental metal fabrication, and how do you overcome them?

- Complex designs: Use specialized cutting and forming techniques.

- Precision welding: Employ skilled welders and use specialized welding equipment.

- Material selection: Choose alloys and grades appropriate for the project’s requirements and environment.

- Cost constraints: Optimize material usage, explore fabrication techniques, and negotiate effectively with suppliers.

- Safety hazards: Implement proper safety protocols, use protective gear, and follow industry regulations.

4. How do you ensure the quality of the finished ornamental metal product?

- Rigorous material inspection before fabrication.

- Precision fabrication using calibrated equipment.

- Qualified welders adhering to welding standards.

- Thorough post-fabrication inspection and testing.

- Customer feedback and satisfaction assessments.

5. What are the different surface finishes available for ornamental metalwork, and how do you choose the appropriate finish for a project?

- Polished: High-gloss, mirror-like finish.

- Brushed: Satin-like finish with fine lines.

- Painted: Provides protection and color customization.

- Powder-coated: Durable, corrosion-resistant finish.

- Anodized: Electrolytic process that creates a protective oxide layer.

- Patina: Natural aging process that results in a unique finish.

- Consider the desired appearance and aesthetics.

- Evaluate the environmental conditions and exposure.

- Assess the project’s budget and maintenance requirements.

Choosing the appropriate finish:

6. How do you measure and mark metal accurately for cutting and fabrication?

- Use precision measuring tools such as rulers, tapes, and calipers.

- Mark metal with scribe or soapstone.

- Double-check measurements and markings before cutting.

- Use templates or jigs for repetitive or complex cuts.

7. What are the safety precautions that must be taken when working with ornamental metal?

- Wear appropriate safety gear including gloves, eye protection, and ear protection.

- Use sharp cutting tools and ensure they are properly maintained.

- Be aware of sharp edges and burrs on metal.

- Handle heavy metal with care and use proper lifting techniques.

- Store and transport metal safely to prevent accidents.

8. How do you determine the proper type and size of fasteners for ornamental metalwork?

Factors to consider:

- Material: Type of metal being fastened.

- Load: Weight or force the fastener will bear.

- Environment: Exposure to moisture, temperature, or chemicals.

- Appearance: Visible or hidden fasteners.

Types of fasteners:

- Rivets: Permanent, non-removable fasteners.

- Bolts: Threaded fasteners that can be removed and reused.

- Screws: Threaded fasteners typically used in smaller sizes.

- Nails: Simple, low-strength fasteners.

9. How do you maintain and repair ornamental metalwork to ensure its longevity?

- Regular cleaning to remove dirt and debris.

- Periodic inspection for signs of corrosion or damage.

- Touch-up painting or refinishing to protect the surface.

- Repairs as needed, such as welding cracks or replacing damaged parts.

- Proper storage and handling to prevent scratches or dents.

10. What are the current trends and innovations in ornamental metal fabrication?

- Laser cutting: Precise and intricate cutting.

- Waterjet cutting: Versatile cutting for various materials.

- 3D printing: Rapid prototyping and complex designs.

- Sustainable materials: Environmentally friendly alloys and finishes.

- Advanced welding techniques: Robotic welding and automated processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ornamental Metal Erector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ornamental Metal Erector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ornamental Metal Erectors are responsible for the installation and maintenance of architectural metalwork, including railings, gates, fences, and other decorative metal elements. Key job responsibilities include:

1. Installing ornamental metalwork according to blueprints and specifications

This involves measuring, cutting, and assembling metal components, using hand and power tools, and welding or riveting metal pieces together.

- Reading and understanding blueprints and specifications

- Measuring, cutting, and assembling metal components

- Welding or riveting metal pieces together

2. Maintaining and repairing existing ornamental metalwork

This involves inspecting metalwork for damage, cleaning and lubricating moving parts, and repairing or replacing damaged components.

- Inspecting metalwork for damage

- Cleaning and lubricating moving parts

- Repairing or replacing damaged components

3. Fabricating custom metalwork

This involves working with architects and engineers to design and create custom metalwork pieces, using a variety of metalworking techniques.

- Working with architects and engineers to design and create custom metalwork pieces

- Using a variety of metalworking techniques

4. Safety

Ornamental Metal Erectors must follow all safety regulations and procedures, including wearing appropriate safety gear and using proper tools and equipment.

- Wearing appropriate safety gear

- Using proper tools and equipment

Interview Tips

To ace an interview for an Ornamental Metal Erector position, candidates should prepare by:

1. Researching the company and the position

This will help you to understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, social media pages, and Glassdoor.

- Visiting the company’s website

- Checking the company’s social media pages

- Reading reviews on Glassdoor

2. Practicing your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Preparing answers to common interview questions

- Practicing your answers in advance

3. Bringing a portfolio of your work

This is a great way to showcase your skills and experience to the interviewer. Your portfolio should include examples of your best work, such as photos of completed projects or samples of your metalworking.

- Creating a portfolio of your work

- Including examples of your best work

4. Dressing professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes and shoes, and avoiding casual attire such as jeans or sneakers.

- Wearing clean, pressed clothes

- Avoiding casual attire

Next Step:

Now that you’re armed with the knowledge of Ornamental Metal Erector interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Ornamental Metal Erector positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini