Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Ornamental Metal Worker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Ornamental Metal Worker so you can tailor your answers to impress potential employers.

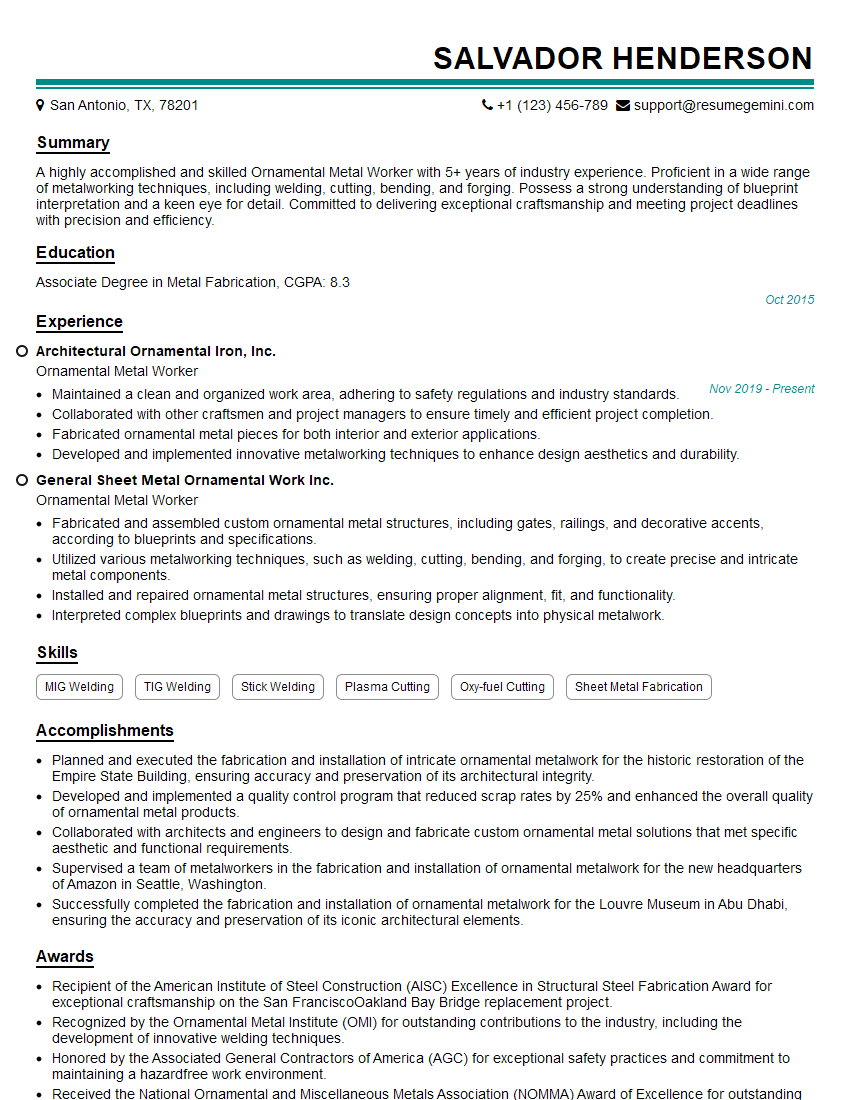

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ornamental Metal Worker

1. What are the different types of ornamental metalwork?

Ornamental metalwork encompasses a wide range of techniques, including:

- Forging: Shaping metal by heating and hammering

- Casting: Creating metal objects by pouring molten metal into a mold

- Welding: Joining metal pieces together using heat or pressure

- Etching: Creating designs on metal surfaces using acids or chemicals

- Anodizing: Creating a protective and decorative oxide layer on aluminum

2. What are the different types of metals used in ornamental metalwork?

The choice of metal depends on the desired aesthetic, durability, and cost:

- Iron: Strong, durable, and relatively inexpensive

- Steel: Stronger than iron, but more expensive

- Aluminum: Lightweight, corrosion-resistant, and easy to work with

- Copper: Malleable, ductile, and aesthetically pleasing

- Stainless steel: Highly corrosion-resistant and durable

3. What are the different tools and equipment used in ornamental metalwork?

Ornamental metalworkers use a variety of specialized tools, including:

- Anvil: A heavy block used as a support for hammering and shaping metal

- Forge: A furnace used to heat metal for forging

- Welding torch: A tool used to join metal pieces together

- Plasma cutter: A tool used to cut intricate designs into metal

- Sandblaster: A tool used to clean and prepare metal surfaces

4. What are the different safety precautions that must be taken when working with metal?

Ornamental metalwork involves working with potentially hazardous materials, so it’s crucial to observe safety precautions:

- Wear protective gear: Including safety glasses, gloves, and a welding helmet

- Handle heavy objects with care: Use proper lifting techniques to avoid injuries

- Use machinery safely: Follow operating instructions and be aware of potential hazards

- Maintain a clean work area: Free of tripping hazards and combustible materials

- Be aware of hot surfaces: Allow equipment to cool before touching

5. What are the typical dimensions of an ornamental metal railing?

Standard railing dimensions vary depending on the specific application, but common sizes include:

- Height: 36-42 inches (91-107 cm) for exterior railings, 30-36 inches (76-91 cm) for interior railings

- Width: 6-8 inches (15-20 cm) for top rails, 3-4 inches (7.6-10 cm) for bottom rails

- Spindle spacing: 4-6 inches (10-15 cm) apart to prevent entrapment

- Post spacing: 6-8 feet (1.8-2.4 meters) apart for stability

6. What is the difference between forging and casting?

Forging and casting are two distinct techniques with different results:

Forging

- Involves shaping metal by hammering and heating

- Produces stronger, denser metal components

- Allows for intricate details and custom designs

Casting

- Involves pouring molten metal into a mold

- Creates complex shapes with high precision

- Produces hollow or thin-walled castings

7. What is the purpose of annealing metal?

Annealing is a heat treatment process that involves heating metal and then slowly cooling it:

- Softening: Annealing makes metal more malleable and ductile, allowing for easier shaping

- Stress relief: It removes internal stresses caused by forging or welding

- Improved machinability: Annealing makes metal easier to cut and drill

8. What are the benefits of using powder-coated finishes on metalwork?

Powder coating offers several advantages for ornamental metalwork:

- Durability: Powder coating provides excellent resistance to corrosion, chipping, and fading

- Aesthetic appeal: Available in a wide range of colors and textures, allowing for customization

- Environmental friendliness: Powder coating uses less solvents and produces fewer emissions than liquid finishes

9. What are the different types of welding joints used in ornamental metalwork?

Ornamental metalworkers use various welding joints to connect metal pieces:

- Butt joint: Joining two flat edges together

- Edge joint: Joining two perpendicular edges together

- T-joint: Joining a perpendicular piece to a flat piece

- Corner joint: Joining two pieces at a right angle

- Miter joint: Joining two pieces at an angle other than 90 degrees

10. What are the challenges of working with stainless steel in ornamental metalwork?

Stainless steel presents unique challenges for ornamental metalworkers:

- Hardness: Difficult to cut and shape compared to other metals

- Heat resistance: Requires careful welding techniques to avoid distortion

- Corrosion resistance: Can be prone to surface scratches and discoloration if not properly finished

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ornamental Metal Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ornamental Metal Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ornamental metal workers are responsible for creating, installing, and repairing ornamental metalwork. Their duties may include:

1. Fabrication and installation of metalwork

Ornamental metal workers fabricate and install a variety of metalwork, including railings, gates, fences, and sculptures. They use a variety of tools and equipment, including welders, grinders, and plasma cutters.

- Fabricate and install ornamental metalwork, such as railings, gates, fences, and sculptures

- Use a variety of tools and equipment

- Follow blueprints and specifications

2. Repair and maintenance of metalwork

Ornamental metal workers also repair and maintain metalwork. They may need to fix broken welds, replace damaged pieces, or repaint metalwork.

- Repair and maintain metalwork

- Fix broken welds

- Replace damaged pieces

- Repaint metalwork

3. Working with other tradespeople

Ornamental metal workers often work with other tradespeople, such as architects, engineers, and contractors. They need to be able to communicate effectively and work as a team.

- Work with other tradespeople

- Communicate effectively

- Work as a team

4. Safety

Ornamental metal workers must follow all safety regulations. They need to wear appropriate protective gear and use tools and equipment safely.

- Follow all safety regulations

- Wear appropriate protective gear

- Use tools and equipment safely

Interview Tips

Here are some interview tips to help you ace your interview for an ornamental metal worker position

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and what they are looking for in a candidate.

- Visit the company’s website

- Read the job description

- Talk to people in your network who work in the industry

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to these questions ahead of time so that you can deliver them confidently and clearly.

- Practice your answers to common interview questions

- Deliver your answers confidently and clearly

- Use the STAR method

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills. Be prepared to talk about your work history, your education, and any other relevant experience.

- Be prepared to talk about your experience and skills

- Highlight your relevant experience and skills

- Quantify your accomplishments

4. Be enthusiastic and professional

The interviewer will be looking for someone who is enthusiastic and passionate about working in the industry. Be sure to show your enthusiasm for the position and for the company.

- Be enthusiastic and professional

- Show your enthusiasm for the position and for the company

- Dress appropriately

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ornamental Metal Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!