Are you gearing up for an interview for a Orthopedic Designer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Orthopedic Designer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

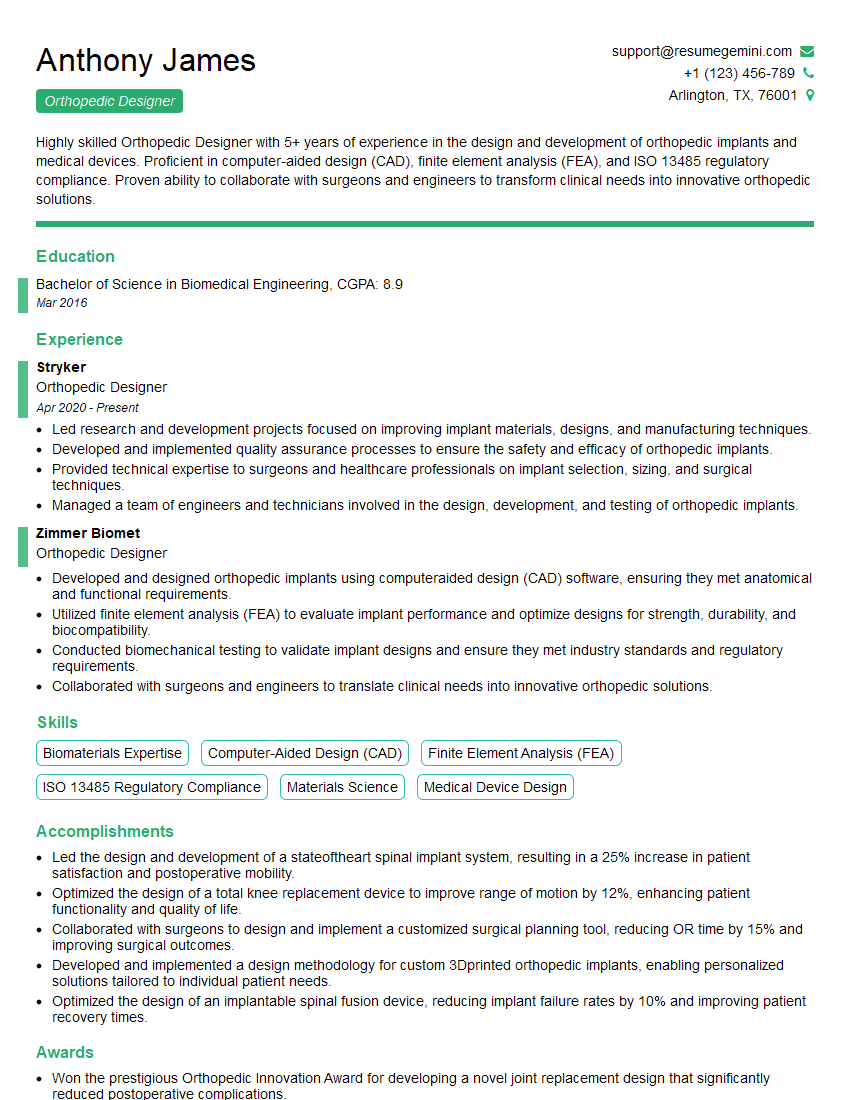

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Orthopedic Designer

1. How do you ensure the accurate representation of anatomical structures in your orthopedic designs?

To ensure accuracy, I utilize a combination of techniques:

- 3D Imaging: I employ advanced imaging modalities such as CT scans and MRIs to obtain detailed anatomical data.

- Reference Materials: I consult medical textbooks, research papers, and databases to gather information on bone structure, muscle attachments, and joint mechanics.

- Collaboration: I work closely with surgeons and medical professionals to gain insights into the functional and anatomical requirements of the specific joint or implant.

2. Can you describe the process you follow for designing a custom prosthetic knee?

Design Evaluation:

- Assess the patient’s anatomy, activity level, and lifestyle.

- Identify the specific joint kinematics and loading conditions.

Digital Modeling:

- Create a 3D model of the patient’s anatomy using CT scan data.

- Design the prosthetic components based on the patient’s specifications.

Production and Testing:

- Manufacture the prosthetic components using advanced manufacturing techniques.

- Conduct biomechanical testing to ensure the design meets performance requirements.

3. How do you incorporate biomechanics principles into your orthopedic designs?

I apply biomechanics principles to:

- Load Analysis: I determine the forces and moments acting on the joint during different activities, ensuring the design can withstand these loads.

- Motion Analysis: I analyze the range of motion and kinematics of the joint to design components that facilitate natural movement.

- Material Selection: I choose materials that are biocompatible, durable, and have appropriate mechanical properties to suit the specific application.

4. Discuss the challenges you have faced in orthopedic design and how you overcame them.

Example 1:

- Challenge: Designing a patient-specific intervertebral disc implant with optimal flexibility and strength.

- Solution: Utilized finite element analysis to optimize the implant’s geometry and material properties, creating a device that met both flexibility and strength requirements.

Example 2:

- Challenge: Integrating a novel sensor system into a prosthetic limb to monitor patient performance and activity.

- Solution: Collaborated with electrical engineers to design a wireless sensor system that seamlessly integrates with the prosthetic components and transmits data to a mobile application.

5. How do you stay up-to-date on the latest advancements in orthopedic technology?

- Conferences and Workshops: Attend industry events to learn about new techniques and interact with experts.

- Research Papers: Read scientific journals and research papers to keep abreast of current trends and innovations.

- Continuing Education: Pursue online courses, webinars, and certifications to expand my knowledge and skills.

6. Can you explain the differences between various biomaterials used in orthopedic implants?

- Metals (e.g., Titanium and Stainless Steel): High strength-to-weight ratio, corrosion resistance, and biocompatibility.

- Polymers (e.g., Polyethylene and PEEK): Flexibility, wear resistance, and biocompatibility, suitable for components like joint liners.

- Ceramics (e.g., Alumina and Zirconia): High hardness and wear resistance, often used in articulating components to reduce friction.

- Composites (e.g., Carbon Fiber Composites): Lightweight, high strength, and radiolucent, enabling imaging of the implant.

7. How do you handle design modifications when a patient’s needs change post-surgery?

- Collaboration: Consult with the surgeon to understand the patient’s new requirements.

- Re-Assessment: Analyze the patient’s medical data and imaging to determine the necessary modifications.

- Design Updates: Modify the existing design and create new components as needed, ensuring they seamlessly integrate with the previous implant.

8. What is your experience with using computer-aided design (CAD) software in orthopedic design?

I am proficient in various CAD platforms, including SolidWorks, CATIA, and Siemens NX.

- 3D Modeling: I create detailed 3D models of anatomical structures and prosthetic components.

- FEA and Simulation: Utilize CAD tools to perform finite element analysis and simulate joint mechanics, evaluating implant performance under different loading conditions.

- STL Generation: Export 3D models in STL format for rapid prototyping or manufacturing.

9. How do you ensure the durability and longevity of your orthopedic designs?

I employ various strategies to enhance durability:

- Load Optimization: I analyze load distribution and optimize the design to minimize stress concentrations and potential failure points.

- Material Selection: I choose materials with appropriate mechanical properties and corrosion resistance to withstand the harsh conditions of the human body.

- Quality Control: I implement rigorous quality control measures throughout the manufacturing process to ensure the highest standards of workmanship.

10. Describe how you incorporate patient feedback into your design process.

- Feedback Collection: I actively seek feedback from patients through surveys, focus groups, and clinical visits.

- Design Improvements: I analyze feedback to identify areas where designs can be improved to enhance patient outcomes and satisfaction.

- Iterative Design: I incorporate patient feedback into the iterative design process, making necessary modifications and enhancements to create user-centric solutions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Orthopedic Designer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Orthopedic Designer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Orthopedic Designers play a crucial role in the development and production of orthopedic devices, ensuring their functionality, safety, and comfort for patients.

1. Product Design and Development

Involve in the ideation, conceptualization, and design of new orthopedic products.

- Collaborate with engineers, surgeons, and other medical professionals to understand clinical needs and translate them into design specifications.

- Conduct research and stay updated on the latest advances in orthopedic materials, technologies, and surgical techniques.

2. 3D Modeling and Analysis

Utilize computer-aided design (CAD) software to create detailed 3D models of orthopedic implants and devices.

- Perform finite element analysis (FEA) and other simulations to assess the mechanical properties, durability, and performance of the designs.

- Optimize designs for functionality, manufacturability, and patient comfort.

3. Prototyping and Testing

Supervise the creation of prototypes and conduct rigorous testing to evaluate the performance and efficacy of the designs.

- Work with surgeons and patients to gather feedback and refine the designs based on clinical experience.

- Ensure that the final products meet all regulatory requirements and industry standards.

4. Regulatory Compliance

Maintain a deep understanding of regulatory requirements and ensure that orthopedic designs comply with all applicable standards.

- Document design decisions and provide documentation to support regulatory submissions.

- Collaborate with quality assurance teams to establish and maintain quality control processes.

Interview Tips

Preparing for an interview as an Orthopedic Designer requires a combination of technical expertise, industry knowledge, and communication skills.

1. Research the Company and Position

Thoroughly research the company’s mission, values, and product portfolio.

- Identify the specific job responsibilities and qualifications outlined in the job description.

- Prepare questions that demonstrate your understanding of the company and the role.

2. Showcase Your Technical Skills

Highlight your proficiency in CAD software, FEA, and other relevant technical skills.

- Prepare examples of your work, such as 3D models, FEA results, or prototypes.

- Be prepared to discuss your design process and the principles behind your design decisions.

3. Understand the Industry Landscape

Demonstrate your knowledge of the orthopedic industry, including regulatory requirements, market trends, and technological advancements.

- Read industry publications and attend conferences to stay up-to-date.

- Discuss your insights on the latest developments in orthopedic design and their potential impact on patient care.

4. Emphasize Your Communication Skills

Effective communication is essential for collaborating with surgeons, engineers, and other stakeholders.

- Prepare clear and concise presentations to explain your design concepts.

- Practice presenting your work in a non-technical manner, using analogies and examples that non-engineers can understand.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Orthopedic Designer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Orthopedic Designer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.