Are you gearing up for an interview for a Orthopedic Shoe Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Orthopedic Shoe Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

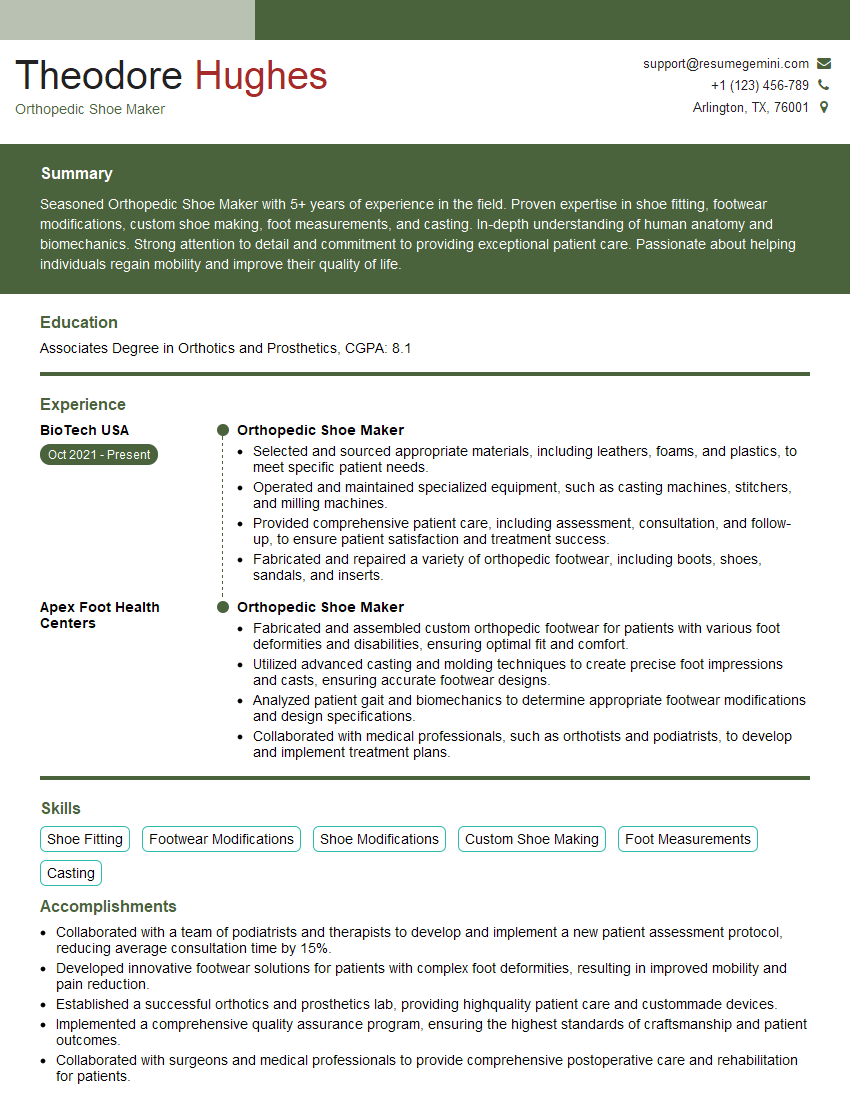

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Orthopedic Shoe Maker

1. What are the different types of orthopedic shoes?

- Accommodative shoes: Designed for individuals with foot deformities or injuries, such as bunions, hammertoes, or heel spurs.

- Corrective shoes: Aim to gradually correct foot deformities, such as flat feet or high arches.

- Protective shoes: Offer protection against injuries, such as diabetic foot ulcers or plantar fasciitis.

- Custom-made shoes: Specifically crafted to meet the unique needs and measurements of individual patients.

2. What materials are commonly used in orthopedic shoemaking?

Natural materials:

- Leather

- Suede

- Canvas

- Cork

Synthetic materials:

- Nylon

- Mesh

- TPU (Thermoplastic Polyurethane)

- EVA (Ethylene Vinyl Acetate)

3. Explain the process of taking a patient’s foot measurements for custom-made shoes.

- Gather necessary tools: measuring tape, casting plaster, and measuring devices.

- Ask the patient to stand and place their foot on a piece of paper.

- Trace the outline of the foot and measure its length, width, and arch height.

- Create a plaster cast of the foot for more precise measurements.

- Measure the angles of the foot and any deformities or irregularities.

4. What are the key considerations when designing orthopedic shoes for a specific patient?

- The patient’s foot anatomy and any deformities.

- The patient’s lifestyle and activities.

- The materials to be used and their suitability for the patient’s needs.

- The level of support and cushioning required.

- The patient’s personal preferences and desired aesthetics.

5. How do you ensure that orthopedic shoes fit comfortably and provide optimal support?

- Take accurate measurements and consider the patient’s foot anatomy.

- Use high-quality materials that provide both comfort and durability.

- Incorporate supportive features such as arch supports, heel counters, and cushioning.

- Allow for adjustments and modifications to ensure a perfect fit over time.

6. What techniques do you use to craft the shoes, from initial design to final assembly?

Initial design:

- Sketch and develop the design based on the patient’s measurements and requirements.

- Create a prototype for testing and refinement.

Crafting:

- Cut and assemble the leather or other materials according to the pattern.

- Install supportive components such as arch supports and heel counters.

- Stitch, glue, or rivet the components securely together.

Final assembly:

- Attach the sole to the upper part of the shoe.

- Perform final adjustments and quality checks.

7. How do you stay up-to-date with the latest advancements in orthopedic shoemaking?

- Attend industry conferences and workshops.

- Read research papers and industry publications.

- Network with other orthopedic shoemakers and professionals.

- Seek feedback from patients and healthcare providers.

8. What are the ethical considerations involved in orthopedic shoemaking?

- Patient safety: Ensuring that shoes meet safety standards and do not harm the patient.

- Patient confidentiality: Maintaining the privacy of patient information and foot measurements.

- Accurate representation: Providing truthful and realistic expectations about the benefits and limitations of orthopedic shoes.

- Compliance with regulations: Adhering to industry standards and regulatory requirements.

9. How do you manage potential challenges in the orthopedic shoemaking process?

- Measurement errors: Correcting mistakes by retaking measurements or creating a new cast.

- Material defects: Identifying and replacing defective materials to ensure durability.

- Patient dissatisfaction: Addressing concerns and making adjustments until the patient is satisfied.

- Production delays: Communicating with patients and adjusting timelines if necessary.

10. What sets you apart from other orthopedic shoemakers?

- Expertise: Extensive knowledge and experience in orthopedic shoe design and construction.

- Attention to detail: Meticulous craftsmanship and commitment to perfection.

- Patient-centered approach: Prioritizing the needs and well-being of patients.

- Involvement in research: Active engagement in advancing the field of orthopedic shoemaking.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Orthopedic Shoe Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Orthopedic Shoe Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An orthopedic shoe maker is a healthcare professional who specializes in the design, fabrication, and fitting of orthopedic shoes and devices to correct or accommodate foot and ankle deformities or injuries. Key job responsibilities include:Taking measurements and impressions of the patient’s feet to create custom-made orthopedic shoes or devices.

1. Designing and Fabricating Orthopedic Shoes and Devices

Designing and fabricating orthopedic shoes and devices based on the patient’s specific needs and requirements, using a variety of materials and techniques.

2. Fitting and Adjusting Orthopedic Shoes and Devices

Fitting and adjusting orthopedic shoes and devices to ensure proper fit, comfort, and functionality.

3. Monitoring and Evaluating Outcomes

Monitoring and evaluating the outcomes of orthopedic shoe or device use, and making adjustments as necessary.

4. Maintaining Records and Documentation

Maintaining accurate records and documentation of patient assessments, shoe or device designs, fittings, and follow-up care.

5. Working with Healthcare Professionals

Working closely with other healthcare professionals, such as podiatrists, orthopedists, and physical therapists, to provide comprehensive patient care.

6. Staying Up-to-Date on Industry Advancements

Staying up-to-date on the latest advancements in orthopedic shoe technology and materials.

Interview Tips

To ace an interview for an Orthopedic Shoe Maker position, candidates should:Be well-prepared with a strong understanding of the key job responsibilities.

1. Research the Company and Industry

Research the company you’re applying to and the orthopedic shoe industry to demonstrate your interest and knowledge.

- Show that you are familiar with the latest advancements in orthopedic shoe technology.

- Learn about the company’s history, values, and market position.

2. Practice Common Interview Questions

Practice answering common interview questions, such as: “Tell me about your experience in designing and fabricating orthopedic shoes.”

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Highlight your skills and experience that are relevant to the job description.

3. Prepare Questions for the Interviewer

Prepare thoughtful questions to ask the interviewer, such as: “What are the company’s goals for the next year?”

- This shows that you are engaged and interested in the position.

- It also allows you to gain more information about the company and the role.

4. Dress Professionally

Dress professionally for the interview, as first impressions matter.

- Choose clothing that is clean, pressed, and appropriate for an office setting.

- Avoid wearing casual clothing or clothing that is too revealing.

5. Be Punctual

Be punctual for your interview.

- Plan your route in advance and allow ample time for travel and parking.

- If you are running late, call or email the interviewer to notify them.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Orthopedic Shoe Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.