Are you gearing up for a career in Outer Diameter Grinder (OD Grinder)? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Outer Diameter Grinder (OD Grinder) and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

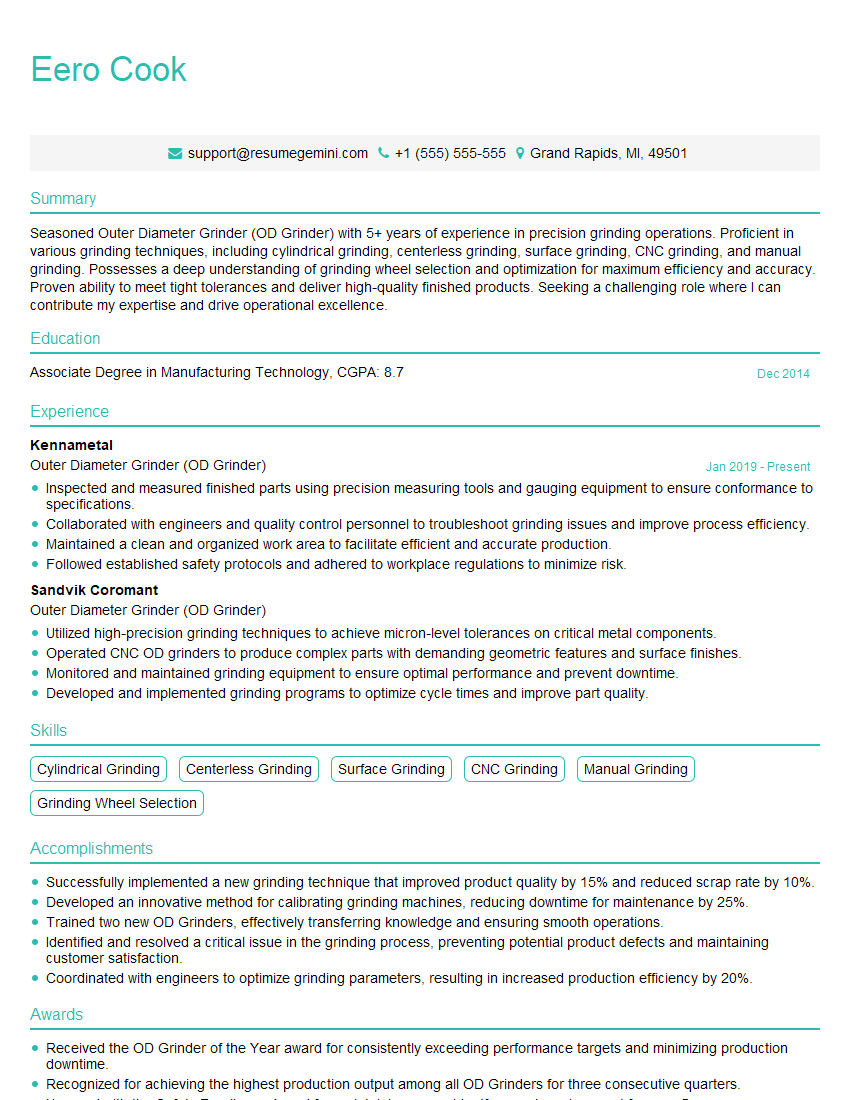

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Outer Diameter Grinder (OD Grinder)

1. Describe the process of setting up an OD grinder?

- Mount the workpiece on the chuck.

- Adjust the chuck speed and feed rate.

- Select the appropriate grinding wheel.

- Position the grinding wheel relative to the workpiece.

- Start the grinding process.

2. What are the different types of OD grinders?

3. What are the safety precautions that must be taken when operating an OD grinder?

- Wear proper safety gear.

- Keep the work area clean and free of debris.

- Inspect the grinding wheel for damage before each use.

- Secure the workpiece properly.

- Never operate the grinder with the wheel guard removed.

4. What are the different types of grinding wheels that can be used on an OD grinder?

- Aluminum oxide wheels

- Silicon carbide wheels

- CBN wheels

- Diamond wheels

5. How do you troubleshoot an OD grinder that is not producing the desired finish?

- Check the grinding wheel for wear or damage.

- Adjust the chuck speed and feed rate.

- Select a different grinding wheel.

- Check the workpiece for defects.

- Calibrate the grinder.

6. What are the different types of coolant systems that can be used on an OD grinder?

- Flood coolant systems

- Mist coolant systems

- Minimum quantity lubrication (MQL) systems

7. What are the advantages and disadvantages of using an OD grinder?

Advantages

- High precision

- Good surface finish

- Versatile

- Affordable

Disadvantages

- Slow

- Can be dangerous

- Requires skilled operators

8. What are the different applications for an OD grinder?

- Grinding shafts and axles

- Grinding gears

- Grinding bearings

- Grinding cutting tools

- Grinding molds and dies

9. What are the latest trends in OD grinding technology?

- The use of CNC controls

- The development of new grinding wheels and coolants

- The integration of automation

10. What are the challenges facing the OD grinding industry?

- The need for increased precision

- The need for reduced costs

- The need for increased productivity

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Outer Diameter Grinder (OD Grinder).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Outer Diameter Grinder (OD Grinder)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Outer Diameter Grinder (OD Grinder) plays a crucial role in the precision grinding and finishing of cylindrical workpieces.

1. Grinding and Finishing

The primary responsibility of an OD Grinder is to grind and finish the outer diameter of cylindrical workpieces.

- Operate OD grinders to grind and finish workpieces to specified tolerances and surface finishes.

- Set up and adjust grinding machines for different workpiece sizes and materials.

- Monitor grinding operations and make adjustments as needed to ensure precision and efficiency.

2. Inspection and Quality Control

OD Grinders are responsible for inspecting and maintaining the quality of their work.

- Inspect finished workpieces using precision measuring tools to ensure compliance with specifications.

- Identify and correct defects or inconsistencies in the grinding process.

- Maintain records of grinding operations and inspection results for quality control purposes.

3. Machine Maintenance and Troubleshooting

OD Grinders are also responsible for maintaining and troubleshooting their equipment.

- Perform routine maintenance tasks on OD grinders, such as cleaning, lubrication, and calibration.

- Identify and troubleshoot equipment malfunctions and make necessary repairs or adjustments.

- Follow established safety protocols and procedures when operating and maintaining grinding equipment.

4. Production Monitoring and Improvement

OD Grinders are involved in monitoring and improving production processes.

- Monitor production schedules and adjust operations to meet deadlines and targets.

- Identify bottlenecks or inefficiencies in the grinding process and suggest improvement measures.

- Contribute to continuous improvement initiatives by providing feedback and suggestions on process optimization.

Interview Tips

Preparing thoroughly for an OD Grinder interview is essential to increase your chances of success.

1. Research the Company and Position

Research the company’s website, industry publications, and social media profiles to gather insights into their values, culture, and specific needs for the OD Grinder role.

- Identify any specific skills, experience, or certifications required for the position.

- Learn about the company’s products, services, and competitive landscape.

2. Practice Your Responses

Anticipate common interview questions and prepare well-structured, concise answers that highlight your relevant skills and experiences.

- Use the STAR method (Situation, Task, Action, Result) to provide specific examples of your accomplishments.

- Quantify your achievements whenever possible to demonstrate the impact of your work.

3. Highlight Your Technical Skills

Emphasize your technical skills and experience in precision grinding and finishing.

- Discuss your knowledge of OD grinding machines, tooling, and grinding techniques.

- Provide examples of how you have used your technical skills to achieve high-quality results.

4. Demonstrate Your Attention to Detail

OD Grinders must have a strong attention to detail and a commitment to precision.

- Highlight your ability to work with high levels of accuracy and precision.

- Share examples of how you have maintained high standards of quality in your previous roles.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Outer Diameter Grinder (OD Grinder) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!