Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Outer Diameter Technician (OD Technician) position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

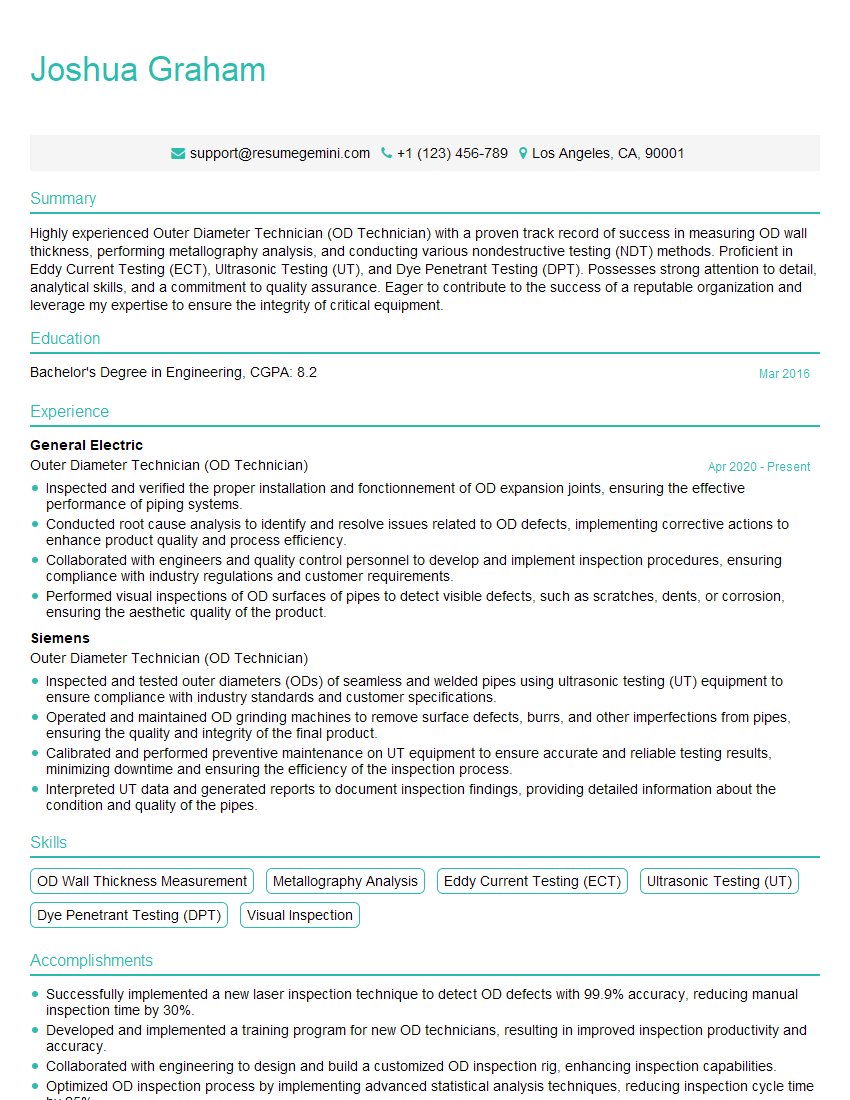

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Outer Diameter Technician (OD Technician)

1. How do you measure the outer diameter of a pipe accurately?

- Start by ensuring that the pipe is clean and free of any dirt or debris that could interfere with the measurement.

- Select the appropriate measuring tool, such as a micrometer, calipers, or a diameter tape.

- Position the measuring tool perpendicular to the pipe’s axis and take the measurement at several points along the length of the pipe.

- Record the measurements and calculate the average to get a precise outer diameter.

- Check the results by comparing them with known standards or specifications.

2. What are the common defects found in welded pipe joints, and how do you inspect them?

- Undercuts: Visual inspection or ultrasonic testing (UT).

- Overlaps: Visual inspection or radiographic testing (RT).

- Cracks: Visual inspection, UT, or magnetic particle testing (MT).

- Porosity: RT or UT.

- Inclusions: RT or UT.

How to inspect:

- Visual inspection: Examine the weld joint for any visible defects.

- UT: Use ultrasonic waves to detect internal defects such as cracks and porosity.

- RT: Use X-rays or gamma rays to create an image of the weld joint and reveal internal defects.

- MT: Apply magnetic particles to the weld joint and use a magnetic field to detect surface cracks.

3. How do you ensure the accuracy of OD measurements, especially when dealing with large-diameter pipes?

- Use precision measuring tools that are calibrated regularly.

- Measure the pipe at multiple points along its circumference to account for any ovality or irregularities.

- Take multiple measurements and calculate the average to minimize errors.

- Use appropriate fixtures or jigs to hold the pipe securely and prevent movement during measurement.

- Ensure that the measuring environment is stable and free from vibrations or other factors that could affect accuracy.

4. How do you handle situations where the measured OD falls outside the specified tolerance range?

- Verify the measurement using a different measuring tool or method.

- Inspect the pipe for any visible defects or damage that may have caused the discrepancy.

- Consult with the supervisor or engineer to determine the next steps, such as re-machining, rejecting the pipe, or seeking alternative solutions.

- Document the findings and any actions taken to ensure traceability and accountability.

5. What is the difference between OD and wall thickness measurement techniques?

- Typically performed using measuring tools like calipers, micrometers, or diameter tapes.

- Measures the distance across the outer surface of the pipe.

- Employs specialized tools like ultrasonic thickness gauges or eddy current testers.

- Measures the thickness of the pipe wall without affecting the inner or outer surfaces.

Outer Diameter (OD) Measurement:

Wall Thickness Measurement:

6. Describe the process of using a micrometer to measure the OD of a pipe.

- Clean the pipe surface and micrometer anvils.

- Set the micrometer to zero using the zero adjustment screw.

- Hold the pipe perpendicular to the micrometer anvils and carefully slide it between them.

- Tighten the thimble until the anvils gently contact the pipe surface.

- Read the measurement on the micrometer scale.

7. How do you calibrate a micrometer?

- Use a standard reference block or gauge with a known dimension.

- Set the micrometer to the reference dimension and lock it.

- Check if the micrometer reading matches the reference dimension. If not, adjust the micrometer’s zero point using the adjustment screw until it aligns.

- Repeat the process with multiple reference points to ensure accuracy across the entire measuring range.

8. What factors can affect the accuracy of OD measurements, and how do you minimize their impact?

- Equipment calibration and maintenance.

- Environmental conditions (temperature, humidity).

- Pipe surface condition (cleanliness, damage).

- Operator skill and technique.

- Use calibrated and well-maintained equipment.

- Control the measuring environment.

- Prepare the pipe surface properly.

- Train and supervise operators to ensure proper measurement techniques.

Factors affecting accuracy:

Minimizing impact:

9. How do you interpret and report OD measurement results?

- Record the measured OD value clearly and accurately.

- Include the measurement uncertainty or tolerance.

- Specify the measuring method and equipment used.

- Compare the results to specified standards or requirements.

- Document any deviations or non-conformances.

10. What are some best practices for ensuring the accuracy and reliability of OD measurements?

- Use calibrated and well-maintained measuring equipment.

- Follow proper measurement techniques and procedures.

- Control the measuring environment.

- Train and supervise operators to ensure consistency.

- Implement a quality control system to monitor and verify the accuracy of measurements.

- Regularly review and update measurement processes to incorporate industry best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Outer Diameter Technician (OD Technician).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Outer Diameter Technician (OD Technician)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Outer Diameter Technicians (OD Technicians) are responsible for the installation, maintenance, and repair of oil and gas pipelines. They work in various environments, including offshore platforms, onshore drilling sites, and refineries.

1. Installation and Maintenance

OD Technicians are involved in the installation and maintenance of pipelines, including laying pipes, welding joints, and testing for leaks. They also inspect and repair existing pipelines to ensure their integrity and prevent potential hazards.

2. Monitoring and Control

OD Technicians monitor and control pipeline operations, including pressure, temperature, and flow rates. They use specialized equipment to monitor the condition of pipelines and identify any issues that may require attention.

3. Safety and Emergency Response

Safety is paramount in the oil and gas industry. OD Technicians are responsible for ensuring that pipelines are operated safely and that proper safety protocols are followed. They also respond to emergencies, such as leaks or spills, and take appropriate action to minimize damage and protect personnel.

4. Maintenance and Repair

OD Technicians perform regular maintenance and repairs on pipelines to keep them in good working condition. They replace worn or damaged components, clean pipelines, and conduct inspections to identify potential issues.

Interview Tips

Preparing for an interview for an Outer Diameter Technician (OD Technician) role is crucial to showcase your skills and make a lasting impression.

1. Research the Company and Position

Take the time to research the company you’re applying to and the specific OD Technician position. Understand their business model, industry experience, and the responsibilities associated with the role. This will help you tailor your answers and demonstrate your interest in the opportunity.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills and experience in pipeline installation, maintenance, and repair. Quantify your accomplishments and provide specific examples of projects you’ve worked on or challenges you’ve overcome. Consider using the STAR method (Situation, Task, Action, Result) to describe your experiences.

3. Showcase Safety Knowledge

Safety is a critical aspect of OD Technician roles. Demonstrate your understanding of safety protocols, regulations, and best practices. Mention any certifications or training you have obtained in this area.

4. Practice and Prepare

Practice answering common interview questions related to the OD Technician position. Prepare for questions about your knowledge of pipeline construction, maintenance techniques, safety procedures, and your ability to work in a team environment.

5. Additional Tips

- Dress professionally and arrive on time for your interview.

- Be confident and enthusiastic about the opportunity.

- Listen carefully to the interviewer’s questions and ask clarifying questions if needed.

- Follow up with the interviewer after the interview to thank them for their time and reiterate your interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Outer Diameter Technician (OD Technician) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!