Are you gearing up for an interview for a Outside Machinist position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Outside Machinist and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

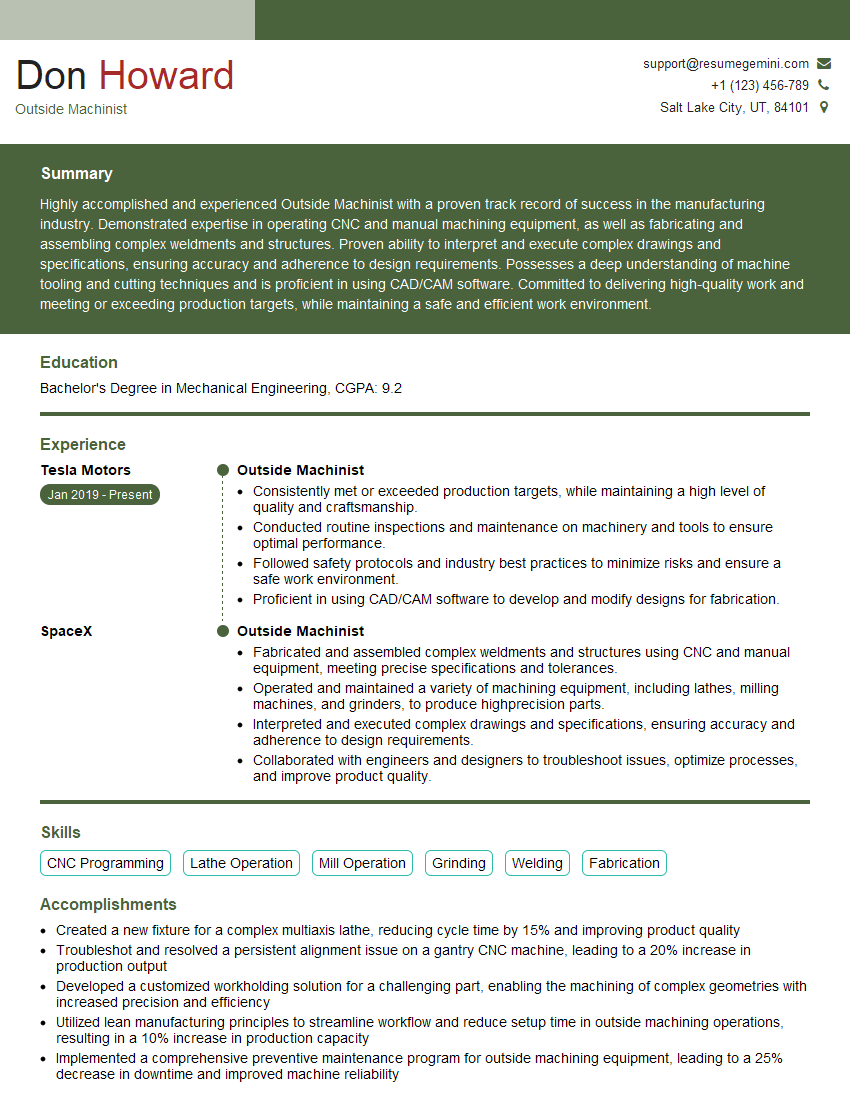

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Outside Machinist

1. How would you ensure the accuracy of measurements when using a micrometer?

- Calibrate the micrometer regularly using a standard.

- Ensure the micrometer is clean and free of dirt or debris.

- Use a light touch when measuring to avoid distorting the material.

- Take multiple measurements and verify the consistency of the results.

2. Describe the process of setting up a lathe for a specific turning operation.

Mounting the workpiece

- Select the appropriate chuck or fixture for the workpiece.

- Clean and center the workpiece in the chuck.

- Tighten the chuck securely.

Setting the cutting tool

- Select the appropriate cutting tool for the material and operation.

- Mount the tool in the tool holder and adjust the height and offset.

- Secure the tool firmly.

Setting the lathe controls

- Set the cutting speed, feed rate, and depth of cut based on the material and tool.

- Set the lathe to the appropriate direction of rotation.

- Engage the machine.

3. How do you troubleshoot a milling machine that is producing rough or uneven surfaces?

- Check the cutting tool for wear or damage.

- Inspect the workpiece for proper clamping and alignment.

- Verify that the cutting speed, feed rate, and depth of cut are appropriate.

- Check the coolant system to ensure it is flowing properly.

- Inspect the machine for any loose or misaligned parts.

4. Describe the different types of welding processes and their applications.

- Arc welding: Uses an electric arc to melt the metal and join two pieces together.

- Subtypes: Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW)

- Oxy-fuel welding: Uses a flame to heat the metal and melt a filler rod.

- Resistance welding: Uses pressure and heat to weld two pieces together by passing an electric current through them.

- Solid-state welding: Joins two pieces together by applying pressure and heat without melting the metal.

5. Explain the principles of heat treatment and how they affect the properties of metal.

- Annealing: Softens the metal and makes it more ductile.

- Normalizing: Refines the grain structure and improves strength.

- Hardening: Increases the hardness and wear resistance.

- Tempering: Reduces hardness and increases toughness.

6. Describe the safety precautions that should be taken when working with rotating machinery.

- Wear proper clothing, including eye protection, gloves, and earplugs.

- Keep hair and loose clothing away from rotating parts.

- Never operate machinery without proper training.

- Lock out and tag out machinery before making repairs.

- Be aware of potential hazards such as sharp edges and hot surfaces.

7. Explain the principles of CNC (Computer Numerical Control) machining.

- CNC machines are controlled by a computer program that tells the machine where to move and cut.

- The program is created using a CAD (Computer-Aided Design) software.

- CNC machines can perform complex operations with high accuracy and repeatability.

8. Describe the different types of materials that can be machined and their machining characteristics.

- Metals: High strength and durability, but can be difficult to machine.

- Plastics: Lightweight and easy to machine, but can be less durable than metals.

- Wood: Relatively soft and easy to machine, but can be prone to warping and shrinkage.

- Composite materials: Combine the properties of different materials, offering versatility and performance advantages.

9. Explain the importance of coolant in machining operations.

- Cools the cutting tool and workpiece, reducing wear and prolonging tool life.

- Lubricates the tool and workpiece, reducing friction and improving surface finish.

- Removes chips and debris from the cutting area, preventing tool clogging and improving machining efficiency.

- Protects the workpiece from corrosion and other damage.

10. Describe the process of measuring angles using a protractor.

- Align the protractor’s baseline with one side of the angle.

- Mark the point where the other side of the angle intersects the protractor’s scale.

- Read the angle from the scale at the marked point.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Outside Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Outside Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Outside Machinist is responsible for operating and maintaining various types of machinery to produce precision metal parts, components, and assemblies. Their primary duties include:

1. Machine Operation

• Set up, operate, and adjust CNC (Computer Numerical Control) machines, lathes, milling machines, and other machine tools to produce parts according to design specifications

• Interpret blueprints, technical drawings, and work orders to determine production parameters

• Select appropriate tooling, fixtures, and cutting fluids based on material properties and machining requirements

2. Quality Control

• Inspect and measure finished parts using precision instruments to ensure they meet tolerance specifications

• Perform quality checks throughout the production process to identify and correct any deviations

• Maintain accurate records of inspection results and any necessary adjustments made to equipment or processes

3. Maintenance and Troubleshooting

• Perform preventive maintenance on machinery and equipment to ensure optimal performance

• Troubleshoot and resolve mechanical, electrical, or software issues that may arise during operation

• Identify and replace worn or damaged parts as necessary

4. Safety and Compliance

• Follow established safety protocols and wear appropriate personal protective equipment (PPE)

• Ensure that the work area is clean, organized, and free from hazards

• Adhere to industry regulations and standards related to machining operations

Interview Tips

To ace the interview for an Outside Machinist position, it is crucial to prepare thoroughly and demonstrate your technical proficiency and practical experience. Here are some tips to help you stand out:

1. Research the Company and Role

• Visit the company’s website, social media pages, and any available annual reports to learn about their business focus, values, and recent developments

• Review the job description carefully and identify the specific skills, experience, and qualifications required for the position

2. Highlight Your Skills and Experience

• Quantify your accomplishments by providing specific examples of projects you’ve worked on and the results you achieved

• Use action verbs and technical terms to describe your experience in operating and maintaining CNC machines, lathes, milling machines, and other equipment

• If possible, prepare a portfolio of your work or bring examples of completed projects to showcase your skills

3. Demonstrate Problem-Solving Abilities

• Discuss situations where you encountered challenges during machining operations and how you identified and resolved the issues

• Emphasize your ability to troubleshoot and repair mechanical, electrical, or software problems efficiently

4. Show Enthusiasm and Passion

• Convey your interest in machining and your eagerness to contribute to the company’s success

• Express your commitment to safety, quality, and continuous improvement

5. Be Prepared for Key Questions

• Anticipate common interview questions related to your machining experience, technical skills, and safety practices

• Practice your answers and prepare specific examples that demonstrate your proficiency and knowledge

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Outside Machinist, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Outside Machinist positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.