Are you gearing up for a career in Outsole Compressor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Outsole Compressor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

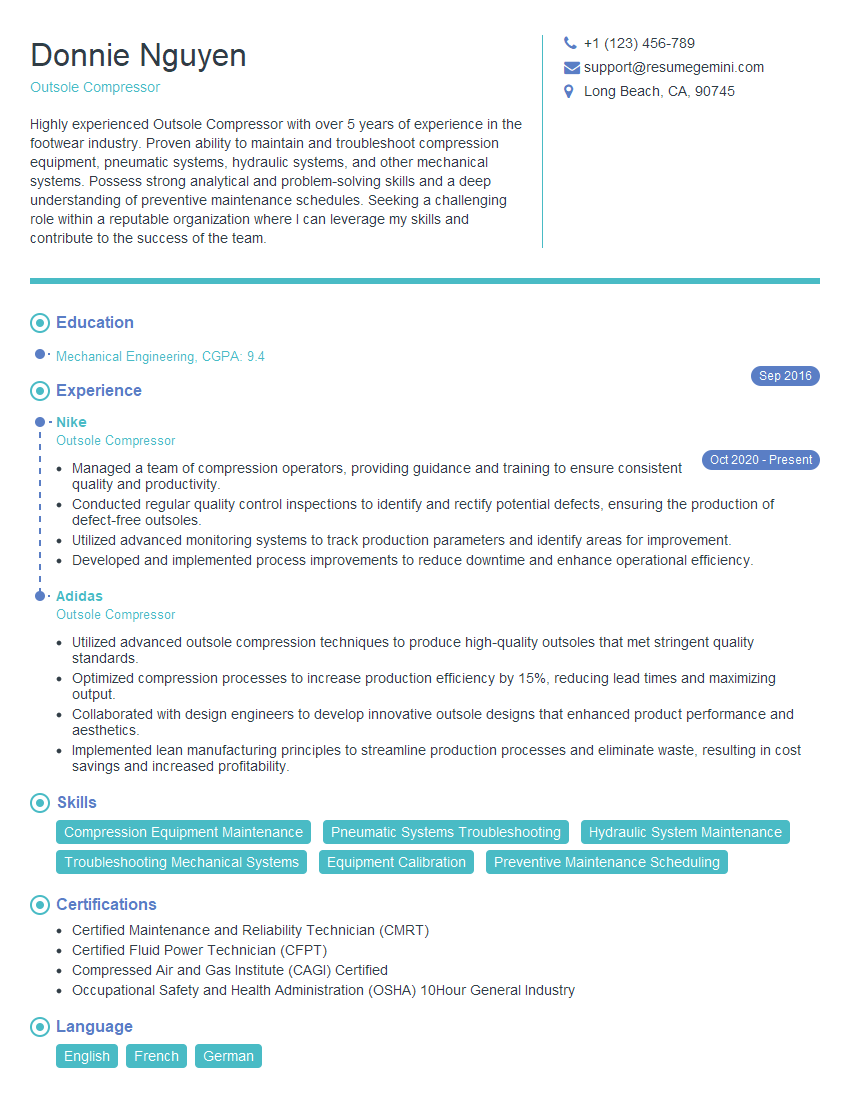

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Outsole Compressor

1. What are the different types of Outsole Compressors?

There are three main types of Outsole Compressors:

- Reciprocating compressors

- Rotary screw compressors

- Centrifugal compressors

2. What are the main components of an Outsole Compressor?

The main components of an Outsole Compressor include:

Compressor housing

- Cylinder

- Piston

- Valves

- Crankshaft

Drive mechanism

- Motor

- Coupling

- Gearbox

Control system

- Pressure switch

- Temperature switch

- Flow switch

3. What are the factors that affect the performance of an Outsole Compressor?

The performance of an Outsole Compressor is affected by several factors, including:

- Type of compressor

- Size of compressor

- Speed of compressor

- Pressure ratio

- Inlet temperature

- Outlet temperature

- Efficiency

4. What are the common problems associated with Outsole Compressors?

The common problems associated with Outsole Compressors include:

- Leaking valves

- Worn piston rings

- Damaged crankshaft

- Overheating

- Vibration

- Noise

5. What are the maintenance requirements for an Outsole Compressor?

The maintenance requirements for an Outsole Compressor include:

- Regular oil changes

- Filter changes

- Valve adjustments

- Bearing inspections

- Leak checks

- Vibration analysis

6. What are the safety precautions that should be taken when working with Outsole Compressors?

The safety precautions that should be taken when working with Outsole Compressors include:

- Wear appropriate personal protective equipment (PPE)

- Follow lockout/tagout procedures

- Be aware of the potential hazards of compressed air

- Do not attempt to repair or service a compressor while it is running

- Have a qualified technician inspect and repair the compressor regularly

7. What are the applications of Outsole Compressors?

Outsole Compressors are used in a wide variety of applications, including:

- Pneumatic tools

- Air compressors

- Refrigeration systems

- Chemical processing

- Oil and gas production

- Mining

- Construction

8. What are the advantages of using Outsole Compressors?

The advantages of using Outsole Compressors include:

- High efficiency

- Reliability

- Durability

- Compact size

- Low maintenance costs

9. What are the disadvantages of using Outsole Compressors?

The disadvantages of using Outsole Compressors include:

- High initial cost

- Noise

- Vibration

- Potential for leaks

10. What are the future trends in Outsole Compressor technology?

The future trends in Outsole Compressor technology include:

- Increased efficiency

- Reduced noise and vibration

- Improved reliability and durability

- Smaller size and weight

- Lower maintenance costs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Outsole Compressor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Outsole Compressor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Outsole compressors play a crucial role in the production of footwear. They are responsible for compressing the outsole of the footwear to the desired shape and thickness, ensuring that it meets the specifications of the design.

1. Compressing Outsoles

The primary responsibility of an outsole compressor is to compress the outsole of the footwear. This involves using specialized equipment to apply pressure to the outsole material, molding it into the desired shape and thickness.

- Operate and maintain compression equipment

- Monitor pressure and temperature levels to ensure proper compression

2. Inspecting Outsoles

After compression, the outsole compressor must inspect the finished product to ensure that it meets the required specifications. This includes checking for defects, such as uneven thickness or surface imperfections.

- Visually inspect outsoles for defects

- Use measuring tools to ensure accurate dimensions

3. Maintaining Equipment

Properly maintaining compression equipment is essential for efficient and safe operation. The outsole compressor is responsible for performing regular maintenance tasks, such as cleaning, lubrication, and minor repairs.

- Clean and lubricate equipment to prevent breakdowns

- Perform basic repairs and troubleshoot common problems

4. Following Safety Procedures

Working in a manufacturing environment requires strict adherence to safety protocols. The outsole compressor must follow all established safety procedures to protect themselves and their colleagues.

- Wear appropriate personal protective equipment (PPE)

- Follow lockout/tagout procedures when servicing equipment

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of making a positive impression and securing the job you want. Here are some tips to help you ace your interview for the position of an Outsole Compressor.

1. Research the Company and Role

Before the interview, take the time to research the company and the specific role you are applying for. This will demonstrate your interest in the position and show that you are prepared.

- Visit the company’s website to learn about their history, mission, and values.

- Read online reviews and articles to gain insights into the company culture and work environment.

- Review the job description to identify the key responsibilities and qualifications for the role.

2. Practice Your Answers

Anticipating common interview questions and practicing your answers can boost your confidence and help you articulate your skills and experience effectively.

- Brainstorm potential questions related to your technical skills, problem-solving abilities, and safety knowledge.

- Prepare concise and compelling answers that highlight your relevant qualifications and experiences.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

3. Be Professional and Enthusiastic

First impressions matter. During the interview, maintain a professional demeanor and show enthusiasm for the position. This includes dressing appropriately, arriving on time, and being polite and respectful to the interviewer.

- Dress in business casual attire to convey professionalism and respect for the interviewer.

- Be punctual for the interview to demonstrate your timeliness and respect for the interviewer’s schedule.

- Greet the interviewer with a firm handshake, make eye contact, and introduce yourself confidently.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the role. It also gives you an opportunity to clarify any uncertainties you may have.

- Prepare questions that are relevant to the role, the company, or the industry.

- Avoid asking questions that can be easily found on the company’s website or in the job description.

- Be specific and ask questions that show you are interested in the details of the position.

5. Follow Up

After the interview, follow up with a thank-you note to the interviewer. This is a simple yet effective way to express your appreciation for the opportunity to interview and reiterate your interest in the position.

- Send a personalized thank-you note within 24 hours of the interview.

- Reiterate your key qualifications and how they align with the role.

- Express your gratitude for the interviewer’s time and consideration.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Outsole Compressor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!