Feeling lost in a sea of interview questions? Landed that dream interview for Outsole Splicer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Outsole Splicer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

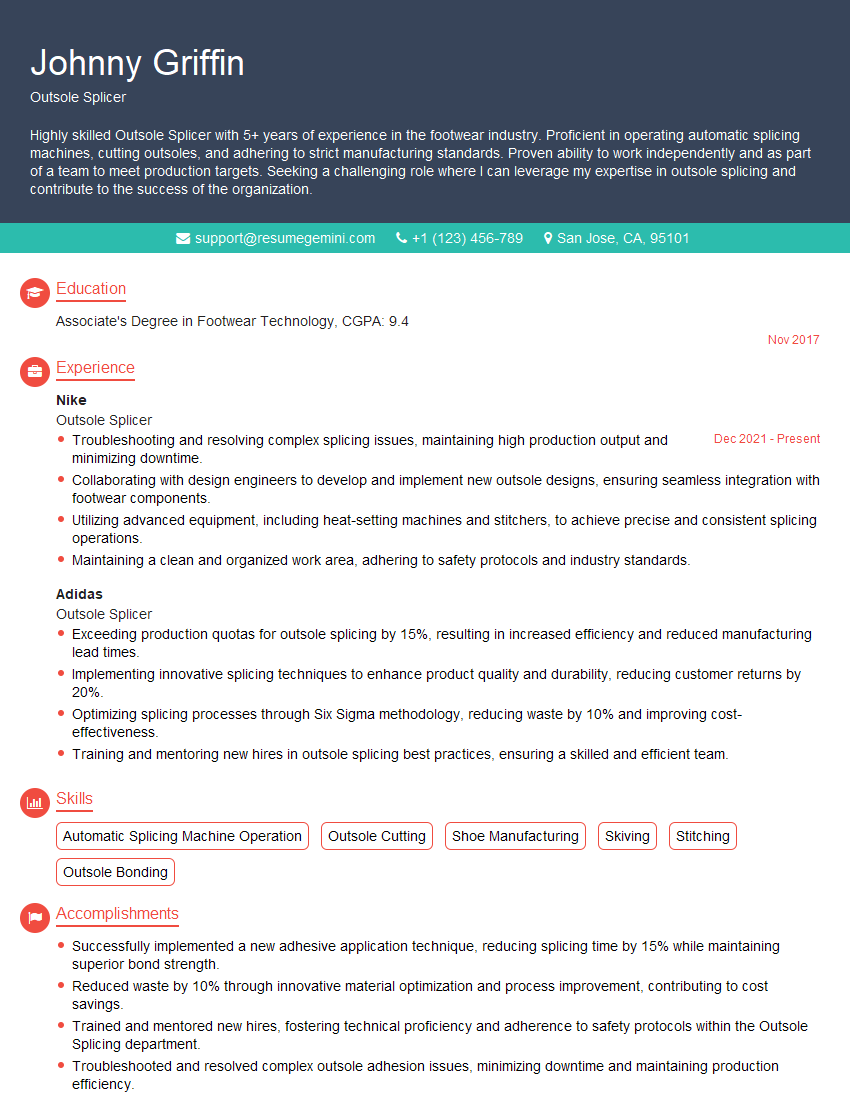

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Outsole Splicer

1. What are the key differences between hot melt and cold cement adhesive for outsole splicing?

Key differences between Hot Melt and Cold Cement Adhesive for Outsole Splicing

- Application Temperature: Hot melt adhesive is applied in liquid form at a high temperature (typically 150-200°C), while cold cement adhesive is applied at room temperature.

- Bonding Strength: Hot melt adhesive provides a higher initial bond strength, while cold cement adhesive has a longer bonding time and gradually achieves higher strength.

- Flexibility: Hot melt adhesive can be more flexible, while cold cement adhesive provides a more rigid bond.

- Water Resistance: Cold cement adhesive generally provides better water resistance than hot melt adhesive.

2. Describe the process of preparing and cleaning an outsole before splicing.

- Roughening the Surface: Use a sanding machine or abrasive paper to remove any dirt, debris, or uneven surfaces on the outsole.

- Cleaning with Solvent: Apply a suitable solvent to a clean cloth and wipe the outsole to remove contaminants and oils.

- Drying: Allow the outsole to dry thoroughly before applying adhesive.

3. How do you ensure accurate alignment of the outsole during splicing?

- Use a Splicing Jig: A splicing jig provides a precise guide for aligning the outsole and midsole.

- Check with Measurement Tools: Use a ruler or caliper to measure and ensure the alignment of the two components.

- Visual Inspection: Carefully inspect the alignment by eye before applying adhesive.

4. What factors determine the bond strength of an outsole splice?

- Adhesive Type: The properties of the adhesive play a crucial role in bond strength.

- Surface Preparation: Proper cleaning and roughening of the outsoles enhances adhesion.

- Alignment: Accurate alignment ensures maximum contact between the surfaces and improves bond strength.

- Pressure and Heat: Applying sufficient pressure and heat during splicing optimizes the bonding process.

5. What are the common problems encountered during outsole splicing and how do you troubleshoot them?

- Poor Bond Strength: Inspect the alignment, surface preparation, and adhesive selection. Verify that the appropriate pressure and heat were applied.

- Gaps in the Splice: Ensure proper alignment and apply adequate pressure during splicing to avoid gaps.

- Rough Surface after Splicing: Use a sanding block or file to smooth the spliced area if necessary.

6. What are the safety precautions to be observed during outsole splicing?

- Wear Safety Gear: Use gloves, eye protection, and a respirator to protect against fumes and particles.

- Handle Adhesives Safely: Follow manufacturer’s instructions for safe handling and disposal of adhesives.

- Ventilate the Work Area: Ensure adequate ventilation to minimize exposure to fumes.

- Proper Storage: Store adhesives and solvents in a well-ventilated area according to manufacturer’s guidelines.

7. How do you maintain and calibrate the equipment used in outsole splicing?

- Regular Cleaning: Keep equipment clean by removing adhesive residues and debris.

- Calibration: Follow manufacturer’s instructions for calibration and verification of temperature and pressure.

- Inspection and Maintenance: Regularly inspect equipment for any wear or damage. Perform necessary repairs or replacements as required.

8. What techniques do you employ to improve the efficiency of outsole splicing?

- Optimize Adhesive Application: Use a calibrated adhesive dispenser to ensure consistent application and minimize waste.

- Minimize Downtime: Keep a clean work area and have all necessary materials within easy reach.

- Train and Motivate Team: Ensure that team members are well-trained and motivated to maintain high productivity.

9. How do you stay updated with the latest advancements in outsole splicing techniques and adhesives?

- Industry Events: Attend conferences, exhibitions, and workshops to learn about new technologies and best practices.

- Trade Publications: Subscribe to industry publications to stay abreast of current trends and innovations.

- Manufacturer Training: Participate in training programs offered by adhesive and equipment manufacturers.

10. How do you ensure the quality of outsole splices and what quality control measures do you implement?

- Visual Inspection: Inspect spliced outsoles for alignment, gaps, and any defects.

- Bond Strength Testing: Perform bond strength tests to verify the adequacy of the splice.

- Adhesive Coverage: Ensure that adhesive is applied evenly and covers the entire bonding surface.

- Process Control: Maintain records of process parameters such as temperature, pressure, and adhesive type to ensure consistency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Outsole Splicer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Outsole Splicer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Outsole Splicer is a vital member of the footwear production team, responsible for joining the outsole to the upper of the shoe. They must possess strong attention to detail and a keen eye for accuracy to ensure that the shoes are assembled correctly and meet quality standards.

1. Join Outsoles to Uppers

Using specialized equipment, the Outsole Splicer securely joins the outsole to the upper of the shoe. They follow precise specifications to ensure proper alignment and bonding.

- Operate outsole splicing machines to bond outsoles to uppers

- Adjust machine settings to achieve optimal bonding results

2. Inspect Splices

Once the outsoles are spliced, the Outsole Splicer carefully inspects the joints to ensure they meet quality standards. They check for proper alignment, bonding strength, and any defects.

- Inspect splices for alignment, bonding strength, and defects

- Identify and address any non-conformance issues

3. Maintain Equipment

To ensure optimal performance and accuracy, the Outsole Splicer maintains the splicing equipment. They perform routine maintenance, troubleshoot problems, and calibrate the machines as needed.

- Clean and maintain splicing equipment

- Troubleshoot and resolve equipment issues

- Calibrate and adjust machines to maintain accuracy

4. Adhere to Safety Protocols

Safety is paramount in the footwear production environment. The Outsole Splicer follows all established safety protocols, including wearing appropriate protective gear and adhering to machine safety guidelines.

- Wear appropriate personal protective equipment (PPE)

- Follow machine safety guidelines and lockout procedures

- Maintain a clean and organized work area

Interview Preparation Tips

To ace the interview for an Outsole Splicer position, it’s crucial to prepare thoroughly. Here are some tips to help you stand out:

1. Research the Company and Position

Before the interview, take the time to research the company’s products, values, and reputation. Understanding the company’s culture and the specific role you’re applying for will demonstrate your interest and commitment.

- Visit the company’s website and social media pages

- Read industry news and articles about the company

- Prepare questions about the company’s sustainability practices or any recent achievements

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers. Practice articulating your skills, experience, and why you’re a suitable candidate for the role.

- Tell me about your experience in splicing outsoles

- Describe a time you identified and resolved a problem with splicing equipment

- How do you ensure accuracy and quality in your work?

3. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience during the interview. Quantify your accomplishments whenever possible to demonstrate your impact.

- Highlight your experience in operating and maintaining outsole splicing machines

- Provide specific examples of how you improved accuracy and efficiency in splicing operations

- Mention any certifications or training in outsole splicing

4. Be Prepared to Discuss Quality Assurance

Quality assurance is crucial in footwear production. Be prepared to discuss your understanding of quality control standards and your approach to ensuring that outsoles are spliced correctly.

- Explain your understanding of ISO 9001 or other relevant quality standards

- Describe your process for inspecting splices and identifying non-conformance issues

- Share examples of how you have contributed to improving quality outcomes in previous roles

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Outsole Splicer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!