Are you gearing up for a career in Overlock Sleeve Setter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Overlock Sleeve Setter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

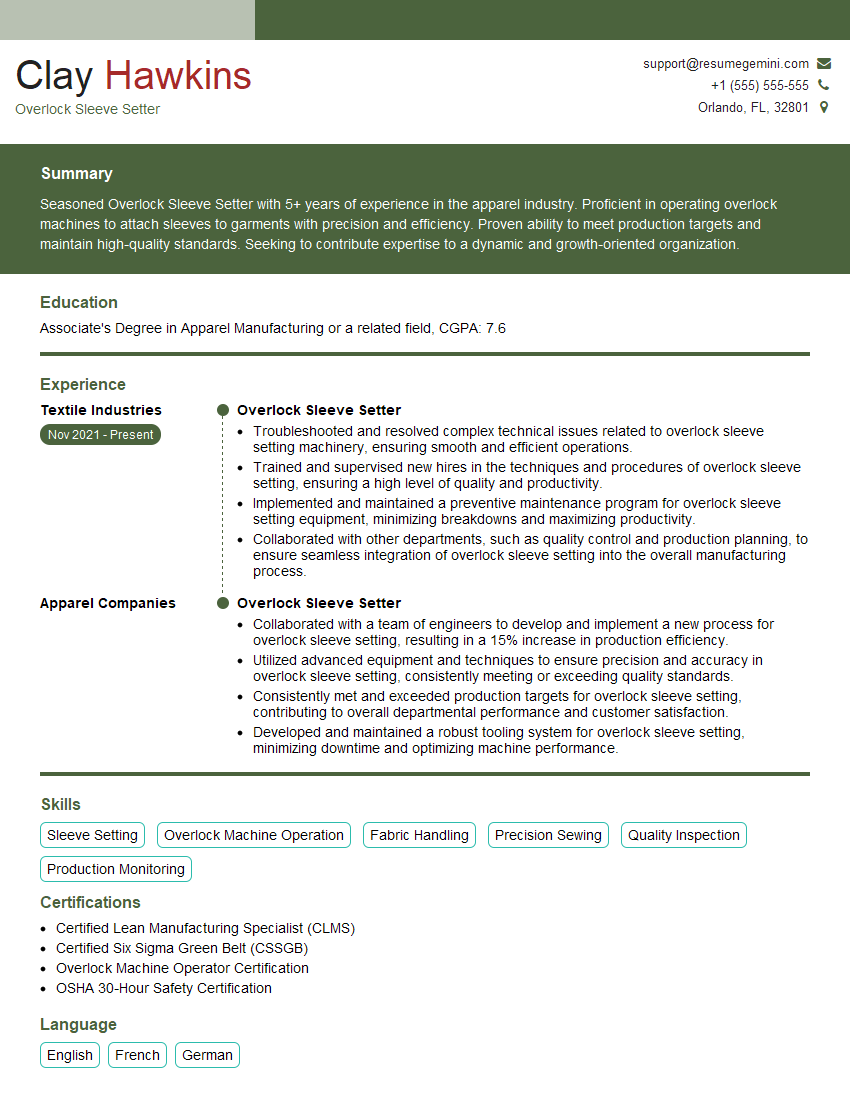

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Overlock Sleeve Setter

1. What are the key responsibilities of an Overlock Sleeve Setter?

As an Overlock Sleeve Setter, my key responsibilities include:

- Set up and operate the overlock sewing machine to sew sleeves into garments

- Inspect and ensure the sleeves are correctly aligned and attached securely

- Adjust machine settings, such as stitch length and tension, to optimize performance

- Maintain the overlock sewing machine, including cleaning and lubrication

- Follow production schedules and meet quality standards

2. What types of overlock sewing machines have you worked with?

Juki

- MO-6916S

- MO-6714S

Brother

- S-7300A

- S-7200C

Pfaff

- 4832

- 4872

3. Can you describe the process of setting up an overlock sewing machine for sleeve setting?

The process of setting up an overlock sewing machine for sleeve setting typically involves the following steps:

- Selecting the appropriate thread and needles for the fabric and garment

- Adjusting the stitch length, tension, and differential feed settings to achieve the desired seam quality

- Positioning the sleeve in the machine and aligning it with the feeder and presser foot

- Threading the machine and ensuring that the tension is correct

- Testing the machine on a scrap piece of fabric to ensure proper operation

4. What are some common problems that can occur during overlock sleeve setting and how do you troubleshoot them?

Some common problems that can occur during overlock sleeve setting and troubleshooting tips include:

- Skipped stitches: Check the needle, thread tension, and fabric thickness

- Puckering: Adjust the differential feed or stitch length

- Uneven seams: Check the presser foot pressure or machine alignment

- Thread breakage: Check the thread quality, tension, and machine threading

- Sleeve not aligned properly: Reposition the sleeve or adjust the machine settings

5. How do you ensure that the sleeves are securely attached and meet quality standards?

To ensure that the sleeves are securely attached and meet quality standards, I adhere to the following practices:

- Inspecting the sleeves before sewing to identify any defects or irregularities

- Using the correct presser foot and tension settings to achieve a strong and durable seam

- Double-checking the alignment of the sleeves and garment before sewing

- Regularly cleaning and maintaining the machine to prevent skipped stitches or uneven seams

- Following established quality control procedures and seeking guidance from supervisors when necessary

6. What safety precautions should be taken when operating an overlock sewing machine?

When operating an overlock sewing machine, it is crucial to prioritize safety by adhering to these precautions:

- Wearing appropriate safety gear, including gloves, safety glasses, and earplugs

- Keeping the work area clean and free of tripping hazards

- Ensuring that the machine is properly grounded and regularly inspected

- Never reaching into the machine while it is running

- Being aware of the location of the emergency stop button and using it promptly if necessary

7. How do you maintain an overlock sewing machine to ensure optimal performance?

To maintain an overlock sewing machine for optimal performance, I follow these key practices:

- Regularly cleaning the machine, including removing lint and thread scraps

- Oiling and lubricating the machine according to the manufacturer’s instructions

- Checking and adjusting the tension settings to prevent skipped stitches

- Inspecting the needles and replacing them when necessary

- Storing the machine in a dry and dust-free environment

8. Can you explain the difference between a 3-thread overlock stitch and a 5-thread overlock stitch?

The key difference between a 3-thread overlock stitch and a 5-thread overlock stitch lies in the number of threads used and the resulting seam construction:

- 3-thread overlock stitch: Uses three threads to create a narrow, stretchy seam with rolled edges, commonly used for finishing seams on garments and fabrics

- 5-thread overlock stitch: Uses five threads to create a wider, stronger seam with a more secure stitch, often used for heavier fabrics or seams that require extra durability

9. What is the importance of differential feed in overlock sleeve setting?

Differential feed plays a crucial role in overlock sleeve setting by allowing for precise control over the fabric feed:

- Prevents puckering or stretching of the fabric by adjusting the feed ratio between the top and bottom feeders

- Ensures a smooth and even seam by compensating for variations in fabric thickness or elasticity

- Improves the overall quality and appearance of the finished sleeve attachment

10. How do you handle working in a fast-paced production environment?

In a fast-paced production environment, I thrive by implementing the following strategies:

- Maintaining a clear understanding of production goals and deadlines

- Prioritizing tasks effectively and managing my time wisely

- Working efficiently and accurately to meet production targets

- Communicating effectively with colleagues and supervisors to ensure smooth operations

- Staying focused and motivated even under pressure

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Overlock Sleeve Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Overlock Sleeve Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Overlock Sleeve Setters are responsible for ensuring the accurate and efficient setting of overlock sleeve machines. Their primary tasks include:

1. Machine Setup and Maintenance

Setting up and maintaining overlock sleeve machines, including adjusting tension, stitch length, and differential feed.

- Troubleshooting and resolving machine malfunctions.

- Performing regular maintenance and cleaning to ensure optimal machine performance.

2. Sleeve Setting

Setting sleeves into garments using overlock sleeve machines.

- Positioning sleeves correctly and aligning them with the garment body.

- Overlocking sleeves to ensure secure and durable attachment.

3. Quality Control

Inspecting overlocked sleeves to ensure they meet quality standards.

- Checking for correct stitch tension, stitch length, and overall appearance.

- Identifying and correcting any defects or irregularities.

4. Production Efficiency

Maximizing production efficiency by optimizing machine settings and minimizing downtime.

- Monitoring machine performance and adjusting parameters to improve productivity.

- Implementing lean principles to reduce waste and streamline processes.

Interview Tips

Preparing thoroughly for an Overlock Sleeve Setter interview can significantly increase your chances of success. Here are some essential tips:

1. Research the Company and the Role

Familiarize yourself with the company’s history, values, and current projects. Research the specific role to understand the key responsibilities and expectations.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in setting up, maintaining, and operating overlock sleeve machines. Showcase your experience in troubleshooting and resolving common machine issues.

3. Demonstrate Attention to Detail

Overlock Sleeve Setters must be meticulous and have a keen eye for detail. Provide examples of your ability to identify and correct defects in overlocked sleeves.

4. Quantify Your Results

Whenever possible, use specific metrics to demonstrate your contributions to previous roles. Quantify your achievements in terms of productivity improvements, quality enhancements, or cost reductions.

5. Prepare for Technical Questions

Be prepared for technical questions related to overlock sleeve setting machines. Review common machine components, troubleshooting techniques, and quality control standards.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Overlock Sleeve Setter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.