Feeling lost in a sea of interview questions? Landed that dream interview for Oxidation Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Oxidation Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

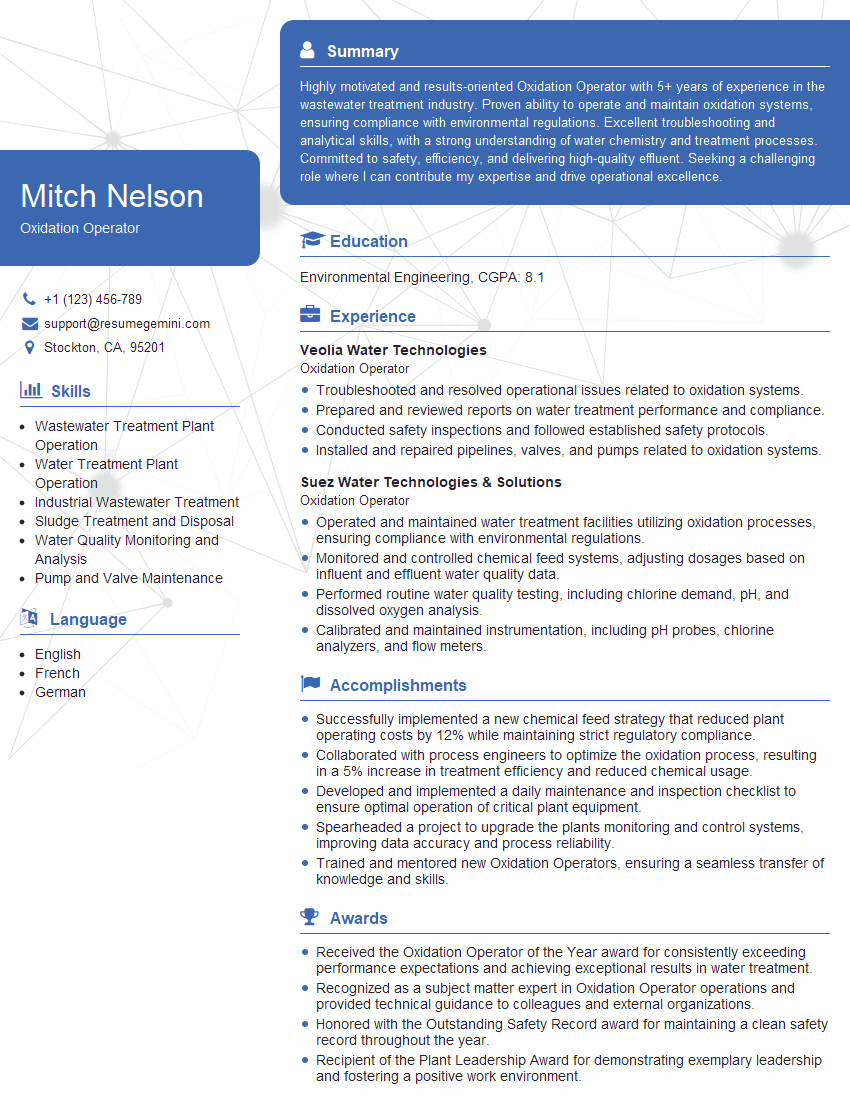

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oxidation Operator

1. Describe the oxidation process and its significance in the industry?

Oxidation is a chemical process that involves the addition of oxygen to a substance. In the industrial context, oxidation is used for a variety of purposes, such as:

- Removing impurities from metals and other materials

- Producing chemicals such as acids and bases

- Generating energy in fuel cells and other devices

2. What are the different types of oxidants used in oxidation processes?

There are a variety of oxidants that can be used in oxidation processes, including:

- Oxygen

- Chlorine

- Hydrogen peroxide

- Potassium permanganate

- Sodium hypochlorite

3. What are the factors that affect the rate of oxidation?

The rate of oxidation is affected by a number of factors, including:

- The concentration of the oxidant

- The temperature of the reaction

- The surface area of the material being oxidized

- The presence of catalysts

4. What are the safety precautions that must be taken when working with oxidants?

Oxidants can be dangerous if not handled properly. The following safety precautions must be taken when working with oxidants:

- Wear appropriate personal protective equipment, including gloves, goggles, and a respirator

- Work in a well-ventilated area

- Keep oxidants away from flammable materials

- Do not mix oxidants with other chemicals unless you are specifically instructed to do so

- Dispose of oxidants properly

5. What are the different methods used to oxidize materials?

There are a number of different methods that can be used to oxidize materials, including:

- Thermal oxidation

- Catalytic oxidation

- Electrochemical oxidation

- Photo oxidation

- Biological oxidation

6. What are the applications of oxidation in the industry?

Oxidation has a wide range of applications in the industry, including:

- Metalworking

- Chemical manufacturing

- Power generation

- Water treatment

- Food processing

7. What are the challenges associated with oxidation processes?

Oxidation processes can be challenging to control, and a number of problems can occur, including:

- Over-oxidation

- Under-oxidation

- Corrosion

- Safety hazards

8. What are the emerging trends in oxidation technology?

A number of emerging trends are shaping the future of oxidation technology, including:

- The development of new, more efficient oxidants

- The use of nanotechnology to improve the performance of oxidation catalysts

- The integration of oxidation processes with other chemical processes

- The development of new, more sustainable oxidation technologies

9. What are the research opportunities in oxidation chemistry?

There are a number of research opportunities in oxidation chemistry, including:

- The development of new, more efficient oxidation catalysts

- The study of the mechanisms of oxidation reactions

- The development of new, more sustainable oxidation technologies

- The use of oxidation chemistry to solve environmental problems

10. How do you see the future of oxidation technology?

I believe that oxidation technology has a bright future. As the world faces challenges such as climate change and the need for new energy sources, oxidation technology will play a vital role in developing solutions to these challenges.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oxidation Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oxidation Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Oxidation Operators are responsible for the safe and efficient operation of the oxidation process in a water treatment plant. Their primary objective is to ensure the removal of impurities and contaminants from raw water, resulting in clean and purified water for distribution. The key job responsibilities of an Oxidation Operator include:

1. Monitor and Control Oxidation Processes

Oxidation Operators constantly monitor the oxidation process to ensure it meets the desired parameters. They adjust chemical dosages, such as chlorine or ozone, to achieve optimal disinfection and oxidation levels. They also monitor water quality, including pH, temperature, and dissolved oxygen, to ensure compliance with regulatory standards.

2. Operate and Maintain Equipment

Oxidation Operators operate and maintain pumps, valves, filters, and other equipment used in the oxidation process. They conduct regular inspections, perform maintenance tasks, and troubleshoot any malfunctions to ensure smooth and efficient operation.

3. Conduct Water Quality Testing

Oxidation Operators conduct various water quality tests to assess the effectiveness of the oxidation process. They analyze water samples to determine the presence of contaminants, such as bacteria, viruses, and chemical pollutants. This data helps ensure the safety and potability of the treated water.

4. Maintain Safety and Compliance

Oxidation Operators adhere to strict safety protocols and regulations while handling chemicals and operating equipment. They wear protective gear, follow established procedures, and participate in safety training to minimize risks and ensure compliance with workplace safety standards.

Interview Tips

To prepare for an interview for the position of Oxidation Operator, it is essential to demonstrate a strong understanding of the job responsibilities and industry best practices. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, gather information about the company, its water treatment operations, and the specific role of the Oxidation Operator. This knowledge will demonstrate your interest and preparedness.

2. Quantify Your Experience

When describing your previous experience, use specific numbers and examples to quantify your accomplishments. For instance, instead of saying “I operated oxidation equipment,” you could say “I successfully managed the oxidation process at a water treatment plant, resulting in a 20% reduction in contaminant levels.”

3. Highlight Your Chemical Knowledge

Oxidation Operators must have a solid understanding of chemistry. Showcase your knowledge of chlorine, ozone, and other chemicals used in the oxidation process, and explain how you apply this knowledge in your work.

4. Emphasize Safety Protocols

Safety is paramount in the operation of oxidation processes. Discuss your commitment to safety and provide examples of how you have implemented safety measures in your previous roles.

5. Be Prepared for Technical Questions

Prepare for questions on specific technical aspects of oxidation processes, such as chemical dosages, equipment maintenance, or water quality testing. Show your ability to troubleshoot and resolve operational issues.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Oxidation Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!