Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Oxide Furnace Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

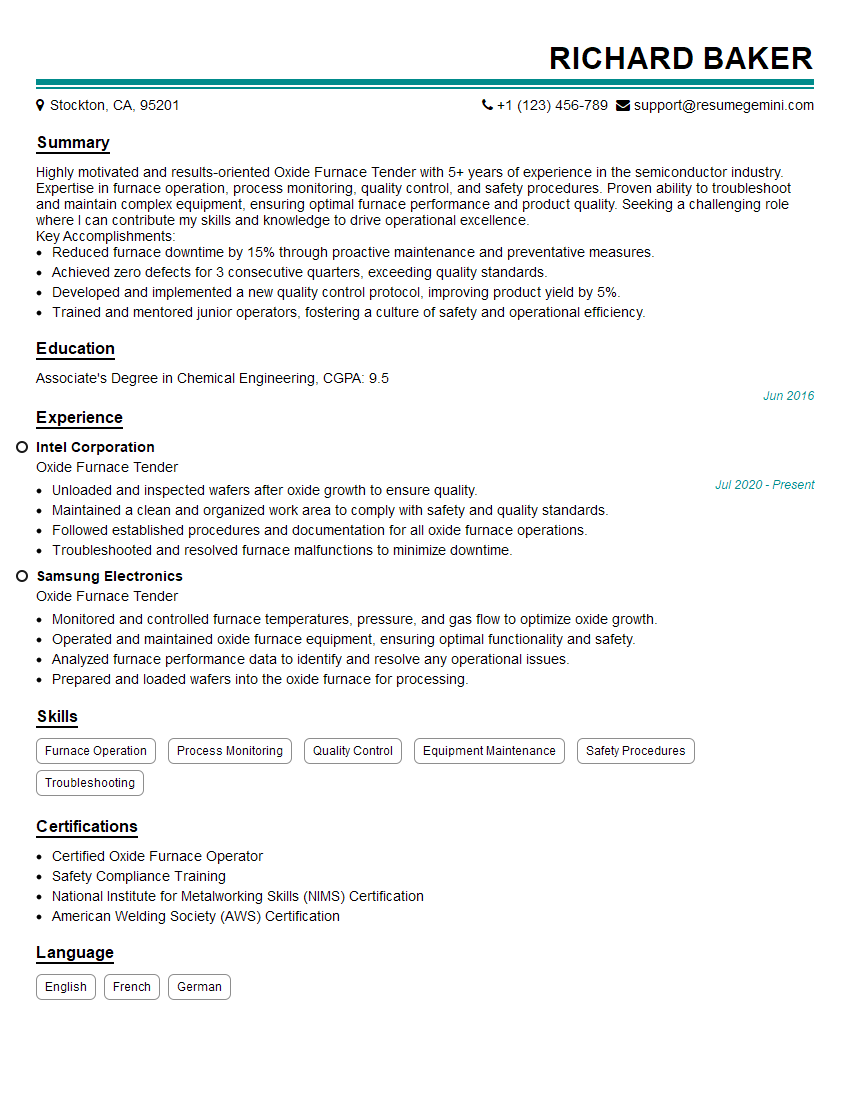

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oxide Furnace Tender

1. What are the key responsibilities of an Oxide Furnace Tender?

As an Oxide Furnace Tender, I expect to be responsible for:

- Operating and monitoring oxide furnaces to produce high-grade feedstock for aluminum electrolytic reduction

- Controlling furnace temperature and feed rates to ensure optimal conversion efficiency and product quality

2. What types of oxides are typically processed in an oxide furnace?

Aluminum Oxide

- Alumina trihydrate (ATH)

- Boehmite

Silicon Oxide

- Silica sand

- Quartz

3. How do you ensure the safety and reliability of the furnace operation?

To ensure the safety and reliability of the furnace operation, I follow a comprehensive set of safety protocols and procedures:

- Regularly inspecting the furnace and its components for any signs of wear or damage

- Following established startup and shutdown procedures

- Adhering to strict operating parameters and monitoring safety alarms

4. What types of maintenance tasks do you perform on the oxide furnace?

I perform routine maintenance tasks to keep the oxide furnace in optimal condition:

- Cleaning and replacing furnace linings

- Inspecting and repairing burners and fuel systems

- Calibrating and maintaining instrumentation and controls

5. How do you handle deviations from the furnace operating parameters?

When deviations from the furnace operating parameters occur, I take the following steps:

- Identify the root cause of the deviation

- Adjust process variables to bring the furnace back within specifications

- Document the deviation and corrective actions taken

6. What is the role of quality control in oxide furnace operation?

Quality control is crucial in oxide furnace operation. I perform the following quality checks:

- Sampling and analyzing feedstock and finished products

- Ensuring compliance with product specifications

- Maintaining records of quality control data

7. How do you optimize furnace efficiency to maximize production?

To optimize furnace efficiency and maximize production, I implement the following strategies:

- Fine-tuning process parameters such as temperature, feed rate, and fuel flow

- Minimizing downtime through proactive maintenance and predictive analytics

- Utilizing advanced control systems to automate furnace operation

8. What is the importance of environmental compliance in oxide furnace operation?

Environmental compliance is paramount in oxide furnace operation. I ensure that the furnace meets all applicable environmental regulations by:

- Controlling emissions through efficient fuel combustion and pollution control devices

- Properly handling and disposing of waste materials

- Monitoring environmental parameters and reporting any deviations

9. What are the safety hazards associated with oxide furnace operation and how do you mitigate them?

Oxide furnace operation involves the following safety hazards:

High Temperatures

- Wear appropriate protective gear

- Follow lockout/tagout procedures

Toxic Emissions

- Ensure proper ventilation

- Use respiratory protection when necessary

10. How do you stay up-to-date with the latest technologies and best practices in oxide furnace operation?

To stay current with the latest technologies and best practices, I engage in:

- Attending industry conferences and webinars

- Reading technical journals and publications

- Seeking mentorship from experienced furnace operators

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oxide Furnace Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oxide Furnace Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Oxide Furnace Tender is responsible for the operation of an oxide furnace, which is used to produce copper and other metals. The key job responsibilities include:

1. Furnace Operation

The Oxide Furnace Tender is responsible for the safe and efficient operation of the oxide furnace. This includes preparing the furnace for operation, charging the furnace with raw materials, monitoring the furnace temperature and pressure, and regulating the flow of oxygen and fuel to the furnace.

- Monitor the furnace temperature and pressure to ensure that they are within the specified operating range.

- Regulate the flow of oxygen and fuel to the furnace to maintain the desired temperature and pressure.

- Charge the furnace with raw materials, such as copper ore, flux, and coke.

- Maintain the furnace by cleaning and repairing it as needed.

2. Product Quality Control

The Oxide Furnace Tender is responsible for ensuring that the product produced by the furnace meets the required quality standards. This includes sampling and testing the product, and making adjustments to the furnace operation as needed.

- Sample and test the product to ensure that it meets the required quality standards.

- Make adjustments to the furnace operation as needed to improve the product quality.

- Keep records of the furnace operation and product quality.

3. Safety and Maintenance

The Oxide Furnace Tender is responsible for ensuring that the furnace is operated safely and that all maintenance is performed according to schedule. This includes following all safety procedures, wearing appropriate protective gear, and maintaining the furnace in good working order.

- Follow all safety procedures and wear appropriate protective gear.

- Maintain the furnace in good working order by performing regular maintenance and repairs.

- Keep records of all maintenance and repairs performed.

Interview Tips

To ace an interview for an Oxide Furnace Tender position, it is important to be prepared and to demonstrate your knowledge and skills. Here are some tips to help you prepare for your interview:

1. Research the Company and the Position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture and values, and the specific requirements of the job. You can find information about the company on its website, in industry publications, and on social media.

- Visit the company’s website to learn about its history, products, and services.

- Read industry publications to learn about the latest trends and developments in the industry.

- Follow the company on social media to get a sense of its culture and values.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Prepare a brief introduction of yourself, including your education, work experience, and skills.

- Practice answering the question “Why are you interested in this position?” by highlighting your skills and experience that are relevant to the job.

- Prepare for other common interview questions, such as “What are your strengths?” and “What are your weaknesses?”.

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time for your interview. Punctuality shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Choose clothing that is clean, pressed, and appropriate for a professional setting.

- Arrive for your interview at least 15 minutes early.

- Bring a portfolio or binder with copies of your resume, transcripts, and any other relevant documents.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic about the position and who are positive about their abilities. Be sure to demonstrate your enthusiasm and positivity during your interview. This will make you more appealing to the interviewer and will increase your chances of getting the job.

- Smile and make eye contact with the interviewer.

- Be positive and enthusiastic about your skills and experience.

- Ask questions about the company and the position to show your interest.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Oxide Furnace Tender role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.