Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Oxidizer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

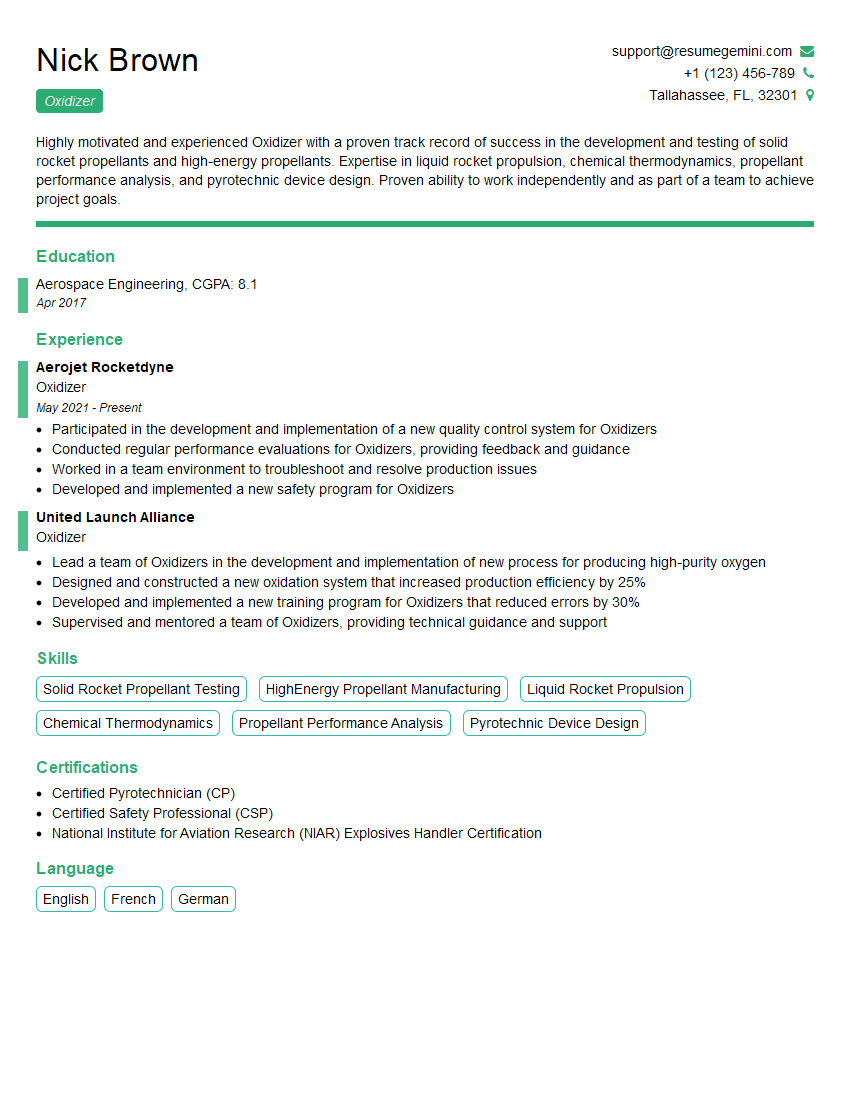

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oxidizer

1. What are the key responsibilities of an Oxidizer?

As an Oxidizer, I am responsible for:

- Operating and maintaining oxidizer systems, including monitoring, troubleshooting, and performing preventive maintenance.

- Adhering to all safety protocols and procedures, including wearing appropriate personal protective equipment and following lockout/tagout procedures.

- Collaborating with other team members to ensure the safe and efficient operation of the oxidizer system.

2. Describe the different types of oxidizers and their applications.

Chemical Oxidizers

- Hydrogen peroxide (H2O2): Used in rocket propulsion, bleaching, and water treatment.

- Potassium permanganate (KMnO4): Used in water purification, deodorization, and disinfection.

Electrochemical Oxidizers

- Ozone (O3): Used in air and water purification, odor control, and bleaching.

- Chlorine (Cl2): Used in water disinfection, bleaching, and industrial processes.

Thermal Oxidizers

- Regenerative thermal oxidizers (RTOs): Used to destroy hazardous air pollutants (HAPs) and volatile organic compounds (VOCs).

- Catalytic oxidizers: Used to convert VOCs into carbon dioxide and water using a catalyst.

3. What are the safety hazards associated with working with oxidizers?

- Fire and explosion risks: Oxidizers can react violently with flammable materials, such as fuels and organic solvents.

- Chemical burns: Oxidizers can cause severe chemical burns if they come into contact with skin or eyes.

- Respiratory hazards: Exposure to high concentrations of oxidizers can cause respiratory irritation, coughing, and shortness of breath.

4. What are the key performance indicators (KPIs) for an Oxidizer?

- System uptime: The percentage of time the oxidizer system is operational.

- Emissions compliance: The ability to meet or exceed regulatory emissions standards.

- Energy efficiency: The amount of energy consumed by the oxidizer system.

- Safety record: The number of accidents or incidents involving the oxidizer system.

5. What troubleshooting techniques do you use to resolve common oxidizer system issues?

- Monitoring system parameters: Checking for abnormal readings in pressure, temperature, flow rate, and other key parameters.

- Inspecting equipment: Visually inspecting the oxidizer system for leaks, blockages, or other damage.

- Cleaning and maintenance: Regularly cleaning and maintaining the oxidizer system to prevent buildup and ensure optimal performance.

- Consulting with experts: If necessary, consulting with manufacturers, engineers, or other experts to identify and resolve complex issues.

6. What is your understanding of the different types of control systems used in oxidizer systems?

- Manual control: The oxidizer system is controlled by an operator through manual adjustments.

- Automatic control: The oxidizer system is controlled by a computer or programmable logic controller (PLC) that adjusts parameters based on setpoints.

- Supervisory control and data acquisition (SCADA) systems: These systems provide remote monitoring and control of the oxidizer system, allowing operators to adjust parameters and track data from a central location.

7. Describe your experience with process optimization techniques as they relate to oxidizer systems.

- Data analysis: Analyzing data from the oxidizer system to identify areas for improvement in efficiency, emissions, and safety.

- Process modeling: Using mathematical models to simulate the oxidizer system and predict its performance under different conditions.

- Optimization algorithms: Applying optimization algorithms to find the optimal operating parameters for the oxidizer system.

8. How do you stay up-to-date on the latest technologies and trends in the field of oxidizer systems?

- Attending conferences and workshops

- Reading industry publications

- Participating in online forums

- Networking with other professionals

9. What are your strengths as an Oxidizer?

- Strong understanding of oxidizer systems and their applications

- Proven ability to operate and maintain oxidizer systems safely and efficiently

- Excellent troubleshooting skills

- Experience with process optimization techniques

- Commitment to continuous learning and professional development

10. What are your career goals and how does this position align with them?

- My career goal is to become a lead Oxidizer and eventually a supervisor in the field of environmental protection.

- This position aligns with my goals by providing me with the opportunity to further develop my skills and knowledge in oxidizer systems and their applications.

- In addition, I am confident that my strong work ethic and dedication will enable me to make a significant contribution to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oxidizer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oxidizer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Oxidizer plays a crucial role in the rocket propulsion system, hence the key job responsibilities involve handling and managing oxidizers.

1. Oxidizer Handling and Management

Assures safe and efficient handling, storage, and transportation of oxidizers.

- Effectively manages oxidizer inventory, ensuring timely replenishment and proper storage conditions.

- Conducts regular inspections and maintenance of oxidizer storage and handling facilities.

2. Quality Control and Assurance

Maintains the integrity and quality of oxidizers throughout the handling process.

- Conducts quality checks and tests to ensure oxidizers meet specified standards.

- Implements and monitors quality control measures to prevent contamination or degradation of oxidizers.

3. Safety Protocols and Compliance

Upholds strict adherence to safety regulations and industry best practices.

- In-depth knowledge of hazardous materials handling procedures and emergency response protocols.

- Ensures compliance with environmental regulations and disposal guidelines for oxidizers.

4. Technical Knowledge and Problem-Solving

Possesses a strong understanding of oxidizer properties, behavior, and potential hazards.

- Effectively troubleshoots and resolves technical issues related to oxidizer handling and storage.

- Contributes to the development and optimization of oxidizer handling procedures.

Interview Tips

To excel in an Oxidizer interview, thorough preparation is essential. Here are proven tips and hacks to ace it:

1. Research the Company and Role

Gain an in-depth understanding of the company’s mission, products, and industry standing.

- Review the job description meticulously, highlighting key responsibilities and required skills.

- Visit the company website and social media pages to gather insights into their culture and values.

2. Highlight Relevant Skills and Experience

Tailor your resume and cover letter to emphasize your transferable skills and previous experience relevant to the Oxidizer role.

- Quantify your accomplishments using specific metrics and results.

- Showcase your expertise in hazardous materials handling, quality control, and safety protocols.

3. Prepare for Technical Questions

Expect questions testing your knowledge of oxidizer chemistry, properties, and handling techniques.

- Refresh your understanding of oxidizer reactivity, stability, and compatibility.

- Practice answering questions about safety procedures and emergency response plans.

4. Showcase Your Problem-Solving Abilities

Interviewers often evaluate your ability to solve problems related to oxidizer handling and storage.

- Prepare examples of how you have successfully resolved technical issues or implemented improvements.

- Demonstrate your analytical thinking and attention to detail.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Oxidizer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!