Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Oxyacetylene Welder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

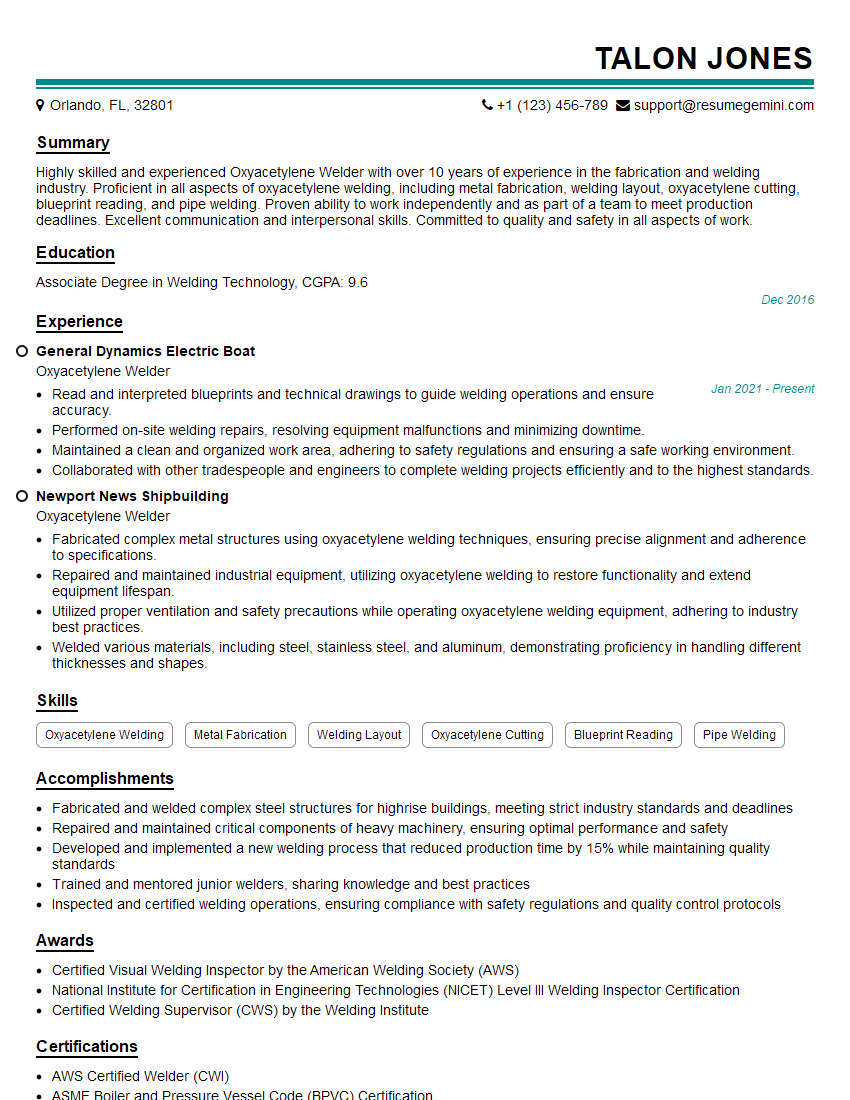

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oxyacetylene Welder

1. What are the different types of welding joints?

- Butt joint

- Edge joint

- T-joint

- Corner joint

- Lap joint

2. What are the steps involved in oxyacetylene welding?

Setting up the equipment

- Attach the acetylene tank to the regulator.

- Attach the acetylene regulator to the torch.

- Attach the oxygen tank to the regulator.

- Attach the oxygen regulator to the torch.

- Open the acetylene tank valve.

- Open the acetylene regulator valve.

- Open the oxygen tank valve.

- Open the oxygen regulator valve.

Lighting the torch

- Hold the torch in one hand and the striker in the other hand.

- Open the acetylene valve on the torch.

- Strike the striker against the flint.

- Close the acetylene valve on the torch.

Adjusting the flame

- Open the acetylene valve on the torch.

- Open the oxygen valve on the torch.

- Adjust the acetylene and oxygen valves to achieve a neutral flame.

Welding

- Hold the torch in one hand and the welding rod in the other hand.

- Melt the base metal and the welding rod.

- Fuse the base metal and the welding rod together.

3. What are the safety precautions that must be taken when oxyacetylene welding?

- Wear appropriate safety gear, including a welding helmet, gloves, and apron.

- Ensure that the work area is well-ventilated.

- Keep the welding torch away from flammable materials.

- Do not weld on closed containers.

- Be aware of the fire hazards associated with oxyacetylene welding.

4. What are the common defects that can occur in oxyacetylene welds?

- Porosity

- Inclusions

- Undercut

- Overcut

- Lack of fusion

5. How do you prevent defects in oxyacetylene welds?

- Use clean welding materials.

- Use the correct welding technique.

- Maintain the proper welding parameters.

- Inspect the weld after welding.

6. What are the applications of oxyacetylene welding?

- Welding metal

- Cutting metal

- Brazing

- Soldering

- Heating metal

7. What are the advantages of oxyacetylene welding?

- Portable

- Versatile

- Relatively inexpensive

- Produces high-quality welds

8. What are the disadvantages of oxyacetylene welding?

- Requires a lot of skill to operate

- Can be dangerous if not used properly

- Produces a lot of heat

- Can be slow compared to other welding processes

9. What is the difference between oxyacetylene welding and arc welding?

- Oxyacetylene welding uses a flame to melt the metal, while arc welding uses an electric arc to melt the metal.

- Oxyacetylene welding is a slower process than arc welding.

- Oxyacetylene welding is more versatile than arc welding, as it can be used to weld a wider variety of metals.

10. What is the best way to learn oxyacetylene welding?

- Take a welding class.

- Practice welding on scrap metal.

- Read books and articles about oxyacetylene welding.

- Get advice from experienced welders.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oxyacetylene Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oxyacetylene Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Oxyacetylene welders play a crucial role in various industries, employing a specialized technique to join metal pieces using an oxyacetylene torch.

1. Welding and Fabrication

The primary responsibility is to weld and fabricate metal components based on specifications and blueprints.

- Prepare and assemble metal pieces for welding.

- Use oxyacetylene equipment to cut, shape, and weld metals.

2. Reading and Interpreting Blueprints

Welder must accurately interpret technical drawings and blueprints to understand the intended design and dimensions.

- Analyze blueprints to determine the type, size, and location of welds.

- Identify potential issues and make necessary adjustments.

3. Quality Control and Inspection

Ensuring the quality and safety of welded components is essential.

- Perform visual inspections and non-destructive testing methods to assess weld integrity.

- Adhere to safety regulations and industry standards.

4. Equipment Maintenance

Maintaining and calibrating oxyacetylene equipment is crucial for safety and efficiency.

- Inspect and maintain welding torches, regulators, and other equipment.

- Troubleshoot equipment issues and perform repairs as needed.

Interview Tips

Preparing thoroughly for an Oxyacetylene Welder interview can significantly increase your chances of success.

1. Research the Company and Position

Familiarize yourself with the company’s background, values, and specific requirements for the position.

- Visit the company website and social media pages.

- Review the job description and identify keywords.

2. Practice Your Skills

Review basic welding techniques, safety protocols, and the use of oxyacetylene equipment.

- Consider practicing on scrap metal or joining materials similar to those used in the position.

- Highlight your proficiency in reading and interpreting blueprints.

3. Demonstrate Your Knowledge

During the interview, confidently articulate your understanding of oxyacetylene welding principles, equipment operation, and safety measures.

- Provide examples of projects where you successfully applied these skills.

- Discuss your experience with different types of metals and welding techniques.

4. Highlight Your Safety Mindset

Emphasize your commitment to safety in the workplace.

- Describe your knowledge of industry regulations and best practices.

- Share examples of how you prioritize safety in your welding operations.

5. Prepare Questions

Asking thoughtful questions shows interest and engagement during the interview.

- Inquire about the company’s welding standards and quality control processes.

- Ask about opportunities for professional development and advancement.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Oxyacetylene Welder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Oxyacetylene Welder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.