Feeling lost in a sea of interview questions? Landed that dream interview for Pack Master but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Pack Master interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

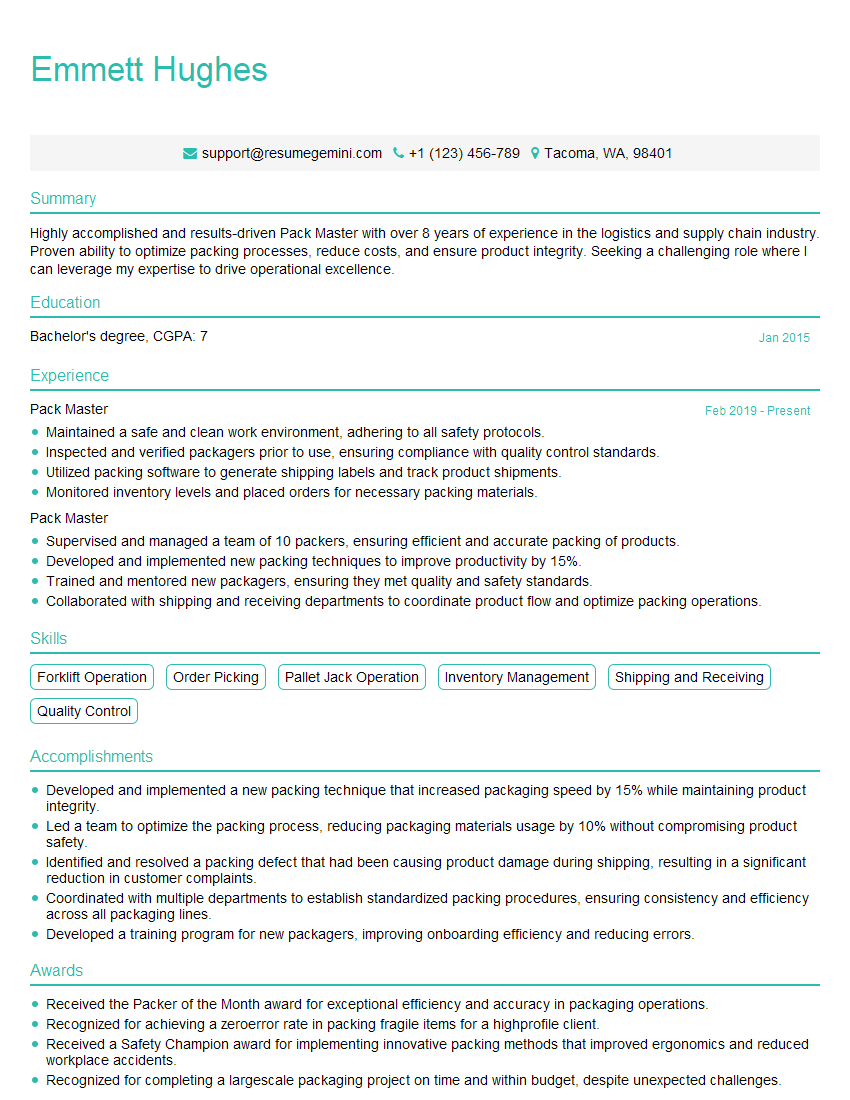

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pack Master

1. How would you ensure that all products are packed according to customer specifications?

To guarantee that all products are packaged according to customer requirements, I would take the following steps:

- Review customer orders thoroughly to understand their specific packaging instructions.

- Train and supervise my team on correct packaging techniques and quality standards.

- Establish clear and concise work instructions and checklists to guide the packing process.

- Implement a quality control system to inspect and verify the accuracy of packaging.

- Regularly monitor and evaluate packaging operations to identify and address any areas for improvement.

2. What types of packaging materials are commonly used in the industry?

Rigid Packaging

- Corrugated cardboard boxes

- Plastic containers

- Metal cans

Flexible Packaging

- Plastic bags and pouches

- Paper bags and sacks

- Aluminum foil

3. How would you handle a situation where there is a shortage of a particular packaging material?

In the event of a packaging material shortage, I would take the following steps:

- Assess the severity of the shortage and its potential impact on operations.

- Explore alternative packaging options that meet customer specifications and quality standards.

- Communicate with suppliers to understand the estimated delivery time for the missing material.

- Prioritize the allocation of available materials to ensure critical orders are fulfilled.

- Keep customers informed of any potential delays or changes in packaging.

4. What are the key safety considerations when operating packaging machinery?

When operating packaging machinery, it is crucial to prioritize safety by adhering to the following considerations:

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Receive thorough training and certification on the specific machinery being operated.

- Follow established safety protocols and lockout/tagout procedures.

- Inspect machinery regularly and report any potential hazards or malfunctions.

- Maintain a clean and organized work area to prevent accidents.

5. How do you stay up-to-date with the latest packaging trends and technologies?

To stay abreast of the latest packaging trends and technologies, I actively engage in the following practices:

- Attend industry conferences and webinars.

- Read trade publications and online resources.

- Network with other professionals in the packaging field.

- Research and evaluate new packaging materials and technologies.

- Attend workshops and training programs to enhance my knowledge and skills.

6. What is the importance of proper storage and handling of packaging materials?

Proper storage and handling of packaging materials are essential for several reasons:

- Maintain quality: Protect packaging materials from damage, contamination, and deterioration.

- Prevent shortages: Ensure adequate inventory levels to meet production demands.

- Reduce waste: Minimize spoilage and damage to materials, reducing costs and environmental impact.

- Safety: Store materials safely to prevent accidents, such as falls or punctures.

- Organization: Maintain a well-organized storage system for efficient access and retrieval.

7. Describe the different methods used to seal packages effectively.

There are several methods used to seal packages effectively:

- Pressure-sensitive adhesives: Self-adhesive tapes are applied to the package surface and pressed together.

- Heat sealing: Heat is applied to seal plastic or foil packaging materials.

- Ultrasonic sealing: High-frequency sound waves create vibrations that fuse packaging materials together.

- Impulse sealing: Short bursts of heat and pressure are used to seal plastic or foil packaging.

- Vacuum sealing: Air is removed from the package before sealing, creating a vacuum to preserve contents.

8. What is your experience with using automated packaging systems?

I have extensive experience in operating and maintaining automated packaging systems, including:

- Horizontal and vertical form-fill-seal machines

- Case erectors and sealers

- Pallet wrappers and stretch hooders

- Conveyor systems and robotics

- Programmable logic controllers (PLCs)

I am proficient in troubleshooting, maintenance, and optimizing these systems to ensure efficient and reliable operation.

9. How do you prioritize and manage multiple tasks in a high-volume packaging environment?

In a high-volume packaging environment, I prioritize and manage multiple tasks effectively by:

- Planning and scheduling: Plan my day and allocate time wisely to critical tasks.

- Delegating and training: Delegate tasks to team members and provide clear instructions.

- Utilizing technology: Leverage software and tools to streamline communication, track progress, and optimize processes.

- Continuous improvement: Analyze workflows, identify bottlenecks, and implement solutions to enhance efficiency.

- Staying organized: Maintain a clean and organized workspace to minimize distractions and maximize productivity.

10. How do you handle feedback from customers and colleagues regarding packaging issues?

When receiving feedback from customers or colleagues regarding packaging issues, I take the following steps:

- Active listening: Listen attentively to the feedback to fully understand the concerns.

- Problem analysis: Investigate the issue thoroughly to determine the root cause.

- Solution development: Collaborate with relevant parties to develop and implement effective solutions.

- Communication: Provide clear and timely updates to customers and colleagues on the progress and resolution.

- Continuous improvement: Use feedback to identify areas for improvement and implement measures to prevent similar issues in the future.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pack Master.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pack Master‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pack Masters play a crucial role in warehouse operations by ensuring the efficient and accurate packing and shipping of products. They are responsible for various tasks that involve handling, organizing, and preparing items for distribution.

1. Packing and Shipping

Pack Masters are responsible for packing products securely and according to specified requirements. They may use various packing materials such as boxes, bubble wrap, and packing peanuts to ensure the safe transport of items. They also affix shipping labels and documentation to packages.

- Pack products in accordance with customer orders and shipping guidelines.

- Select appropriate packaging materials based on product size, shape, and weight.

2. Order Verification

Pack Masters ensure the accuracy of orders by verifying the contents against packing lists or invoices. They check for discrepancies in quantity, size, or product specifications to prevent incorrect shipments.

- Compare packing lists with actual products to ensure complete and accurate orders.

- Identify and resolve discrepancies in orders.

3. Inventory Management

Pack Masters assist in inventory management by keeping track of packed items and maintaining inventory records. They may use scanners or other technology to record product movement and ensure accurate inventory levels.

- Maintain inventory records of packed products.

- Update inventory systems to reflect the movement of items.

4. Quality Control

Pack Masters perform quality control checks to ensure that products are packed and shipped in pristine condition. They inspect products for damage or defects before packing and may make repairs or adjustments as necessary.

- Inspect products for damage or defects.

- Report any quality issues to supervisors.

Interview Tips

Preparing for an interview as a Pack Master requires you to showcase your skills and experience in packaging and shipping operations. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Pack Master position. Familiarize yourself with their products, shipping practices, and any industry-specific requirements related to the role.

- Visit the company’s website to learn about their business and operations.

- Read job descriptions carefully to identify the key responsibilities and qualifications.

2. Highlight Your Packaging and Shipping Experience

Emphasize your experience in packing and shipping operations. Discuss your responsibilities, such as packing products, verifying orders, and maintaining inventory. Provide specific examples of your attention to detail and accuracy in these tasks.

- Use the STAR method (Situation, Task, Action, Result) to describe your experiences.

- Quantify your accomplishments whenever possible, using numbers and metrics.

3. Demonstrate Your Problem-Solving Abilities

Pack Masters often encounter challenges in their daily work, such as damaged products or discrepancies in orders. During the interview, highlight your problem-solving abilities and provide examples of how you have handled such situations effectively.

- Describe a time when you identified and resolved a problem in the packing process.

- Explain how your analytical skills helped you find solutions to common packaging and shipping issues.

4. Emphasize Your Physical Capabilities

The role of a Pack Master requires physical capabilities, such as lifting, bending, and standing for extended periods. Be prepared to discuss your physical abilities and highlight any relevant experience in physically demanding roles.

- Provide examples of how you have maintained physical fitness and stamina in previous jobs.

- Mention any certifications or training programs you have completed related to physical safety.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pack Master role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.