Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Package Dyeing Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

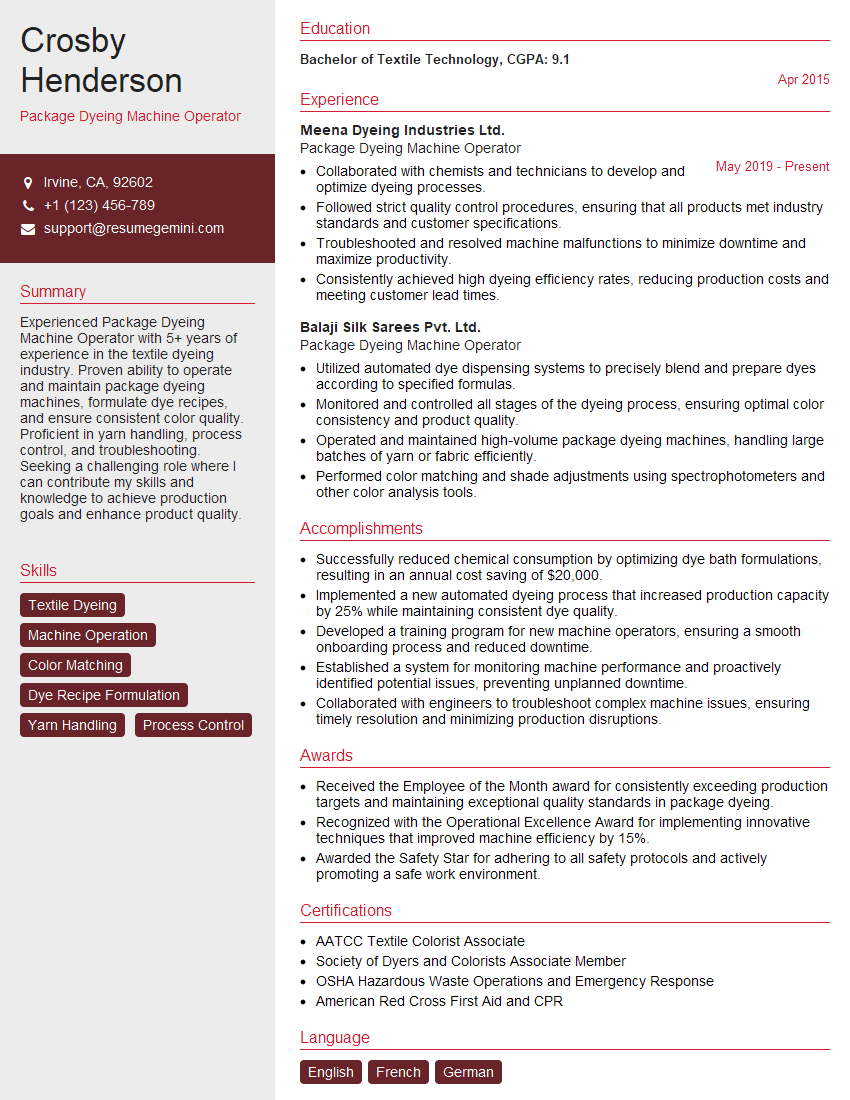

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Package Dyeing Machine Operator

1. How do you ensure the accuracy of the dye solution you prepare?

To ensure the accuracy of the dye solution, I follow a meticulous process involving the following steps:

- Measurement and weighing: I meticulously weigh and measure all dyes and chemicals according to the specified recipe using calibrated scales and measuring devices.

- Dissolving and mixing: I carefully dissolve the dyes and chemicals in water and thoroughly mix them to ensure a uniform and homogeneous solution.

- pH adjustment: I adjust the pH level of the solution using appropriate chemicals to create an optimal environment for the dyeing process.

- Quality control: I regularly conduct quality checks using standardized test methods to verify the accuracy of the dye solution and make necessary adjustments as needed.

2. Describe the steps involved in loading and unloading the package dyeing machine.

Loading the machine

- Preparing the packages: I ensure that the yarn packages are properly wound, free of knots or tangles, and meet the required specifications.

- Loading the spindle: I carefully load the packages onto the spindles of the dyeing machine, ensuring they are evenly spaced and secured.

- Adjusting tension: I adjust the tension on the packages to ensure they are held taut but without excessive strain.

Unloading the machine

- Stopping the machine: I safely stop the dyeing cycle and allow the machine to cool down.

- Removing the packages: I carefully unload the yarn packages from the spindles, taking precautions to prevent damage.

- Inspecting the packages: I inspect the packages for any defects or uneven dyeing and make note of any observations.

3. How do you maintain and troubleshoot the package dyeing machine?

To maintain and troubleshoot the package dyeing machine, I undertake the following tasks:

- Regular maintenance: I perform routine maintenance checks and cleaning to ensure optimal performance, including:

- Lubricating moving parts

- Checking and tightening belts

- Cleaning filters and screens

- Troubleshooting: I am skilled in identifying and addressing common issues with the machine, such as:

- Temperature fluctuations

- Uneven dye distribution

- Leaks or blockages

- Collaboration: If I encounter complex issues beyond my expertise, I promptly collaborate with maintenance technicians or engineers to resolve them.

4. How do you calculate the amount of dye required for a specific batch of yarn?

To calculate the amount of dye required for a specific batch of yarn, I follow these steps:

- Determine shade and depth: I consult the dye recipe or color swatch to identify the desired shade and depth of color.

- Yarn weight and type: I consider the weight and type of yarn to determine the amount of dye it can absorb.

- Dye concentration: I refer to the dye manufacturer’s specifications to determine the recommended concentration for the desired shade.

- Calculation: Using the formula: Dye weight = (Yarn weight x Dye concentration) / 100, I calculate the precise amount of dye required.

5. What are the different types of dyes used in package dyeing?

- Acid dyes: Used on wool, silk, and nylon; have good colorfastness and brightness.

- Basic dyes: Used on acrylic and modacrylic fibers; offer vibrant shades but may have lower washfastness.

- Direct dyes: Suitable for cotton, rayon, and cellulose fibers; provide good color yield and easy application.

- Disperse dyes: Used on hydrophobic fibers like polyester and acetate; offer excellent wash and lightfastness.

- Vat dyes: Durable dyes used on natural fibers like cotton, linen, and hemp; provide high colorfastness and resistance to fading.

6. How do you ensure the quality of the dyed yarn?

To ensure the quality of the dyed yarn, I adhere to the following practices:

- Pre-dyeing testing: I conduct shade trials and fastness tests to verify the suitability of the dye and dyeing process for the specific yarn.

- Color matching: I meticulously compare the dyed yarn to the approved color standard to ensure accurate and consistent color reproduction.

- Fastness testing: I perform rigorous fastness tests to assess the yarn’s resistance to factors such as fading, washing, and rubbing.

- Visual inspection: I carefully inspect the dyed yarn for any defects or unevenness in color or shade.

7. Describe the safety precautions you take when operating the package dyeing machine.

- Personal protective equipment: I always wear appropriate PPE, including gloves, safety glasses, and a respirator when handling dyes and chemicals.

- Machine guarding: I ensure all machine guards and safety devices are in place and functioning properly.

- Chemical handling: I handle dyes and chemicals safely, following established procedures and avoiding direct contact.

- Emergency preparedness: I am familiar with emergency protocols and know how to respond to potential hazards, such as spills or leaks.

8. How do you stay updated on the latest advancements in package dyeing technology?

To stay updated on the latest advancements in package dyeing technology, I:

- Attend industry events and conferences: I participate in trade shows and seminars to learn about new technologies and best practices.

- Read industry publications: I regularly review technical journals and industry magazines to stay informed about innovations.

- Network with peers: I connect with other professionals in the field to exchange knowledge and ideas.

- Continuous learning: I am eager to expand my knowledge and actively seek training opportunities.

9. Can you describe a challenging dyeing project you encountered and how you overcame it?

In a recent project, we encountered a batch of yarn that was unevenly dyed. After careful troubleshooting, we determined that the yarn had not been properly scoured before dyeing. To resolve the issue, we implemented a more thorough scouring process, which successfully removed impurities and allowed the dye to penetrate the yarn evenly. The end result met the desired color specifications and quality standards.

10. Why are you interested in working as a Package Dyeing Machine Operator in our company?

I am eager to join your company as a Package Dyeing Machine Operator because I am confident that my skills and experience align perfectly with your requirements. I am highly proficient in all aspects of package dyeing, from recipe preparation and machine operation to quality control and troubleshooting. Moreover, my dedication to producing high-quality dyed yarn and my passion for continuous improvement make me an ideal candidate for this role. I am enthusiastic about contributing my expertise to your team and helping your company achieve success in the textile industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Package Dyeing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Package Dyeing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Package Dyeing Machine Operators are responsible for operating a range of dyeing machinery, ensuring the production of high-quality dyed packages within the textile industry. Key job responsibilities include:

1. Production Operations

Effectively operate a variety of dyeing machines to dye packages according to specified recipes.

- Load and prepare packages for dyeing.

- Monitor and control dyeing processes based on specified color standards.

- Unpack and inspect the finished product ensuring it meets quality specifications.

2. Process Knowledge

Applying knowledge of dyeing techniques, chemistry and color theory to achieve desired results.

- Interpret dyeing instructions and recipes to accurately dye packages.

- Troubleshoot and resolve dyeing problems efficiently.

3. Equipment Maintenance

Maintaining dyeing equipment to ensure optimal operation and prevent breakdowns.

- Conduct routine cleaning and maintenance of dyeing machines and equipment.

- Identify and report any mechanical or technical issues.

- Follow established safety protocols and procedures to prevent accidents and maintain a safe working environment.

4. Communication and Teamwork

Effectively communicating and collaborating with team members, supervisors, and other departments to achieve production goals.

- Coordinate with production planning to ensure timely delivery of dyed packages.

- Provide technical support and guidance to fellow operators.

- Participate in continuous improvement initiatives.

Interview Tips

Preparation is key to acing any job interview. Here are some tips and hacks to help you prepare for your Package Dyeing Machine Operator interview:

1. Research the Company and Position

Take the time to learn about the company, its products, and the specific responsibilities of the Package Dyeing Machine Operator role. This will give you a strong foundation for answering questions intelligently and demonstrating your interest in the position.

- Visit the company’s website to gather information about their history, mission, and products.

- Review the job description thoroughly to understand the specific requirements and expectations of the role.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in your resume and during the interview. Focus on transferable skills that are applicable to the Package Dyeing Machine Operator role, such as:

- Dyeing and color theory knowledge.

- Experience operating dyeing machinery.

- Understanding of production processes.

- Attention to detail and quality control.

- Problem-solving and troubleshooting abilities.

3. Practice Answering Common Interview Questions

Prepare for common interview questions by practicing your answers in advance. This will help you feel more confident and articulate during the interview. Some common questions you may encounter include:

- Tell me about your experience in operating dyeing machines.

- How do you ensure the accuracy and consistency of dyed packages?

- Describe a time when you had to troubleshoot a problem with a dyeing machine.

- How do you maintain a safe and organized work area?

- What are your strengths and weaknesses as a Package Dyeing Machine Operator?

4. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately for the interview and arrive on time to show that you are professional and respectful of the interviewer’s time. Your appearance and punctuality can make a positive impact on the interviewer.

- Choose business casual attire or formal wear, depending on the company culture.

- Be punctual and arrive for the interview a few minutes early to allow for any unexpected delays.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Package Dyeing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.