Are you gearing up for a career in Packager? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Packager and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

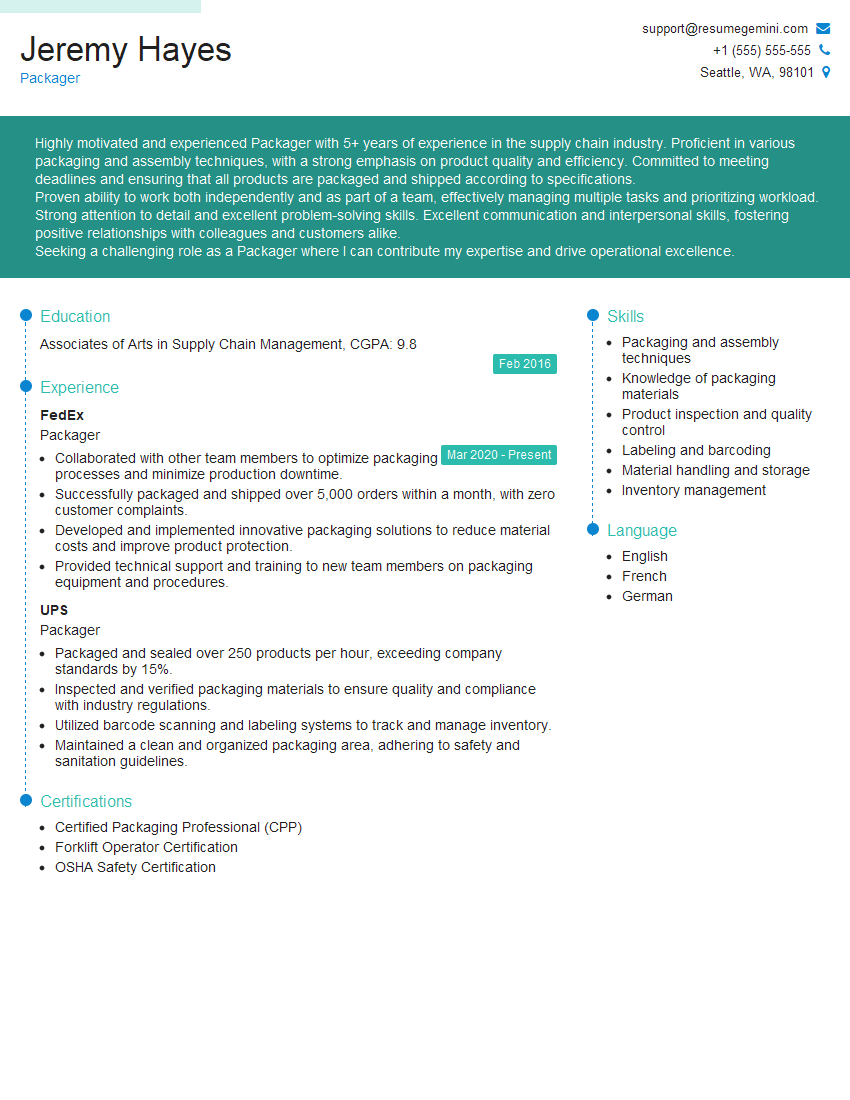

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Packager

1. What are the different types of packaging materials used for food products?

- Flexible packaging: Plastic films, aluminum foil, and paper are used to create flexible packaging that can be formed into various shapes and sizes.

- Rigid packaging: Glass, metal, and plastic containers provide a rigid structure to protect products from damage.

- Semi-rigid packaging: Cardboard boxes, paperboard cartons, and plastic trays offer some protection while allowing for flexibility.

2. What factors should be considered when selecting packaging materials for a food product?

- Product characteristics: The size, shape, weight, and fragility of the product.

- Intended use: The packaging must protect the product during storage, transportation, and handling.

- Marketing considerations: The packaging should enhance the product’s appearance, provide information, and influence consumer choice.

- Environmental concerns: The packaging should be eco-friendly, biodegradable, or recyclable.

3. What methods are used to ensure the quality and safety of packaged food products?

- Barrier packaging: Prevents the entry of oxygen, moisture, and contaminants.

- Vacuum packaging: Removes air from the package to extend shelf life.

- Modified atmosphere packaging: Alters the gas composition within the package to inhibit spoilage.

- Aseptic packaging: Sterilizes the product and packaging before filling.

4. What is the role of packaging in reducing food waste?

- Extended shelf life: Packaging can protect food from spoilage and extend its shelf life.

- Portion control: Packaging can be designed to provide appropriate portion sizes, reducing overconsumption.

- Education and awareness: Packaging can provide consumers with information on proper storage and handling practices.

5. What are the latest trends in food packaging technology?

- Sustainable packaging: Focus on eco-friendly materials, biodegradable films, and reduced packaging waste.

- Active packaging: Incorporates elements that interact with the food to extend shelf life, absorb moisture, or release flavors.

- Smart packaging: Uses sensors and indicators to monitor product quality, provide information, and enhance consumer engagement.

6. What are the ethical considerations involved in food packaging?

- Environmental impact: Minimizing the environmental footprint of packaging materials and waste.

- Food safety: Ensuring that packaging does not contaminate or compromise the safety of food products.

- Consumer transparency: Providing accurate and transparent information about packaging materials and their environmental impact.

7. What is the importance of graphic design in food packaging?

- Product differentiation: Distinctive design helps products stand out in competitive markets.

- Consumer appeal: Eye-catching designs attract consumers and influence purchasing decisions.

- Brand recognition: Consistent brand elements on packaging enhance brand awareness and loyalty.

- Information dissemination: Packaging provides a platform to convey product information, nutritional facts, and marketing messages.

8. What software programs are commonly used for food packaging design?

- Adobe Illustrator

- Adobe Photoshop

- CorelDRAW

- EskoArtwork Suite

- PackEdge

9. What are the regulatory requirements for food packaging?

- Food and Drug Administration (FDA): Ensures the safety of food packaging materials and labeling.

- Environmental Protection Agency (EPA): Regulates the disposal and recycling of packaging materials.

- Consumer Product Safety Commission (CPSC): Enforces safety standards for packaging products.

10. How do you stay updated on the latest developments in food packaging technology?

- Attend industry conferences and trade shows.

- Read trade publications and online resources.

- Network with professionals in the field.

- Conduct research and explore innovative solutions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Packager.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Packager‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Packagers, also known as packaging machine operators, play a crucial role in the manufacturing and distribution industries. Their primary responsibilities involve preparing, packaging, and handling products to ensure their safe and efficient transportation to customers.

1. Packaging and Assembly

Packagers are responsible for assembling and packaging products according to customer specifications and industry standards. This includes selecting appropriate packaging materials, filling containers, labeling and marking products, and securing them for shipment.

- Choose and assemble appropriate packaging materials (e.g., boxes, bags, wraps)

- Fill containers with products and ensure proper weight and count

- Apply labels, stamps, and markings to meet customer and regulatory requirements

- Secure packages with tape, straps, or other methods to ensure stability during transit

2. Inspection and Quality Control

Packagers perform quality checks on packaged products to verify accuracy, completeness, and adherence to specifications. They inspect for any defects, damages, or discrepancies to ensure that products meet the expected standards.

- Check product quantities and weights to match order specifications

- Inspect packaging materials for damage or contamination

- Verify labeling, markings, and documentation for accuracy and compliance

- Report any discrepancies or non-conformances to supervisors

3. Equipment Maintenance and Operation

Packagers operate and maintain packaging equipment to ensure efficient and reliable production. They perform regular cleaning, lubrication, and adjustments to keep machines running smoothly.

- Operate packaging machines (e.g., sealers, shrink wrappers, palletizers)

- Clean and lubricate equipment regularly to prevent breakdowns

- Perform minor troubleshooting and repairs to maintain optimal performance

- Report any major issues or equipment failures to supervisors

4. Safety and Compliance

Packagers adhere to safety regulations and industry best practices to minimize risks and maintain a safe working environment. They wear appropriate protective gear and follow established procedures to prevent accidents.

- Follow established safety protocols and use appropriate protective gear

- Maintain a clean and organized work area to prevent tripping or slipping hazards

- Report any safety concerns or hazards to supervisors

- Comply with all applicable regulations and industry standards

Interview Tips

Preparing thoroughly for a Packager interview can significantly increase your chances of success. Here are some valuable tips and hacks to help you ace the interview:

1. Research the Company and Role

Before the interview, take the time to learn about the company, its products or services, and the specific packaging role you’re applying for. This demonstrates your interest and enthusiasm for the opportunity.

- Visit the company’s website to gather information about its history, mission, and industry standing

- Review the job description carefully and identify the key responsibilities and requirements

- If possible, connect with current or former employees on LinkedIn to gain insights into the company culture and work environment

2. Highlight Relevant Skills and Experience

In your resume and interview answers, focus on emphasizing your skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to provide concrete evidence of your abilities.

- Showcase your proficiency in packaging techniques, equipment operation, and quality control procedures

- Provide specific examples of how you have improved efficiency, reduced waste, or maintained high-quality standards in previous roles

- Mention any certifications or training related to packaging, such as OSHA safety certifications or industry-specific courses

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers beforehand. This will help you present your skills and experience confidently and coherently.

- Tell me about your experience in packaging and quality control

- How do you ensure that products are packaged accurately and efficiently?

- What safety measures do you follow in a packaging environment?

- How do you handle discrepancies or errors in the packaging process?

4. Prepare Industry-Specific Questions

In addition to general interview questions, consider preparing industry-specific questions that show your knowledge and interest in packaging. This can set you apart from other candidates.

- What are the latest trends in packaging technology?

- How does your company approach sustainability in packaging?

- What are the key challenges and opportunities in the packaging industry today?

- What are the quality standards and regulations that apply to the packaging industry?

5. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally and arrive for your interview on time to demonstrate respect for the company and the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Packager interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.