Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Packaging/Filling Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

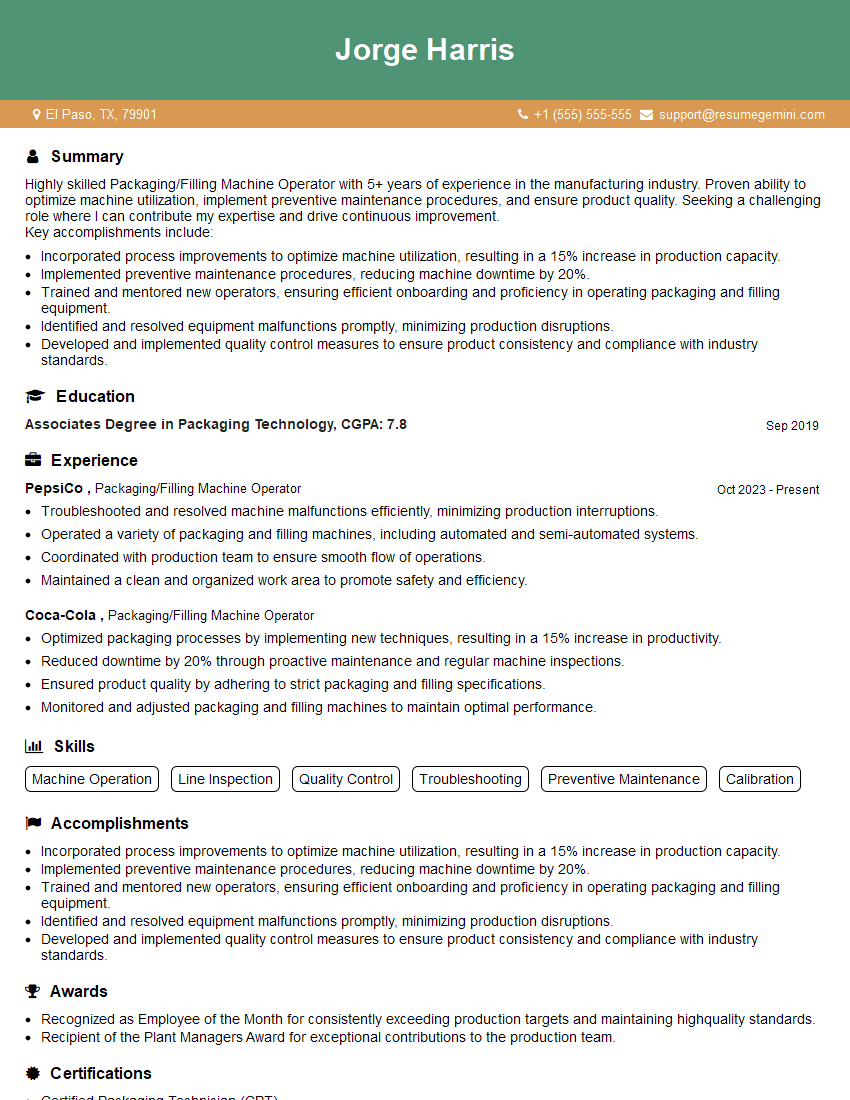

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Packaging/Filling Machine Operator

1. Explain the fundamental principles of a packaging and filling machine?

- Described the primary mechanical components of a packaging and filling machines, such as the enclosure, hopper, conveyor, and sealing mechanisms.

- Clarified the main functions of each component, including product containment, feeding, transport, and package formation and sealing.

- Explained the essential principles of automation in packaging and filling machines, including PLC control, sensors, and drive systems.

2. Describe the different types of packaging and filling machines and their applications?

Types of Packaging Machines

- Form-fill-seal (FFS) machines for creating pouches and bags from flexible materials.

- Vertical form-fill-seal (VFFS) machines for vertical packaging of products in pouches and bags.

- Horizontal form-fill-seal (HFFS) machines for horizontal packaging of products in pouches and bags.

- Thermoforming packaging machines for creating rigid plastic containers from sheet materials.

- Shrink-wrap packaging machines for bundling and protecting products using heat-shrinkable film.

Types of Filling Machines

- Volumetric fillers for dispensing precise volumes of liquid or granular products.

- Gravimetric fillers for highly accurate filling based on product weight.

- Auger fillers for filling powder and granular products.

- Piston fillers for semi-liquid and viscous products.

- Cup fillers for filling preformed cups or containers with liquid or semi-liquid products.

3. What are the key maintenance and troubleshooting procedures for packaging and filling machines?

- Outlined the importance of regular preventative maintenance to ensure optimal machine performance and longevity.

- Described specific maintenance tasks such as cleaning, lubrication, and inspection of critical components.

- Explained common troubleshooting procedures, including identifying potential causes of malfunctions and implementing corrective actions.

4. How do you ensure the accuracy and efficiency of packaging and filling operations?

- Stressed the significance of regular calibration and validation of packaging and filling machines to maintain accuracy.

- Emphasized the importance of monitoring machine performance through data analysis and identifying areas for improvement.

- Outlined strategies for optimizing machine efficiency, such as reducing downtime through proper maintenance and implementing automation.

5. What are the safety protocols and regulations that must be followed when operating packaging and filling machines?

- Highlighted the importance of adhering to established safety protocols and regulations to prevent accidents and injuries.

- Outlined specific safety measures such as wearing appropriate personal protective equipment (PPE), following lockout/tagout procedures, and being aware of potential hazards.

6. Explain how you would handle product changeovers on a packaging and filling line?

- Described the step-by-step procedure for conducting product changeovers efficiently.

- Emphasized the importance of thorough cleaning and sanitization to prevent cross-contamination.

- Outlined the need for proper setup and calibration of the machine for the new product.

7. How do you manage multiple packaging and filling machines simultaneously?

- Explained the importance of effective time management and prioritization.

- Outlined strategies for coordinating multiple machines, including monitoring performance, anticipating potential issues, and delegating tasks.

8. What are the quality control measures you implement to ensure the integrity of packaged products?

- Outlined the importance of maintaining product quality and safety.

- Described specific quality control measures, such as visual inspections, weight checks, and leak testing.

- Emphasized the need for documentation and record-keeping to demonstrate compliance with quality standards.

9. How do you handle machine breakdowns and unexpected events on the packaging and filling line?

- Described the importance of remaining calm and assessing the situation quickly.

- Outlined a step-by-step approach for troubleshooting and resolving machine breakdowns.

- Emphasized the need for effective communication with supervisors and maintenance personnel.

10. How do you stay updated with the latest advancements in packaging and filling technology?

- Outlined the importance of continuous learning and professional development.

- Described specific methods for staying informed, such as attending industry conferences, reading trade publications, and participating in online forums.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Packaging/Filling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Packaging/Filling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Packaging and filling machine operators are responsible for the efficient and safe operation of packaging and filling machinery in a manufacturing or production environment.

1. Machine Operation

intro paragraph

- Operate and monitor packaging and filling machines to ensure optimal performance, efficiency, and product quality.

- Adjust machine settings, such as speed, temperature, and pressure, to meet production requirements.

- Monitor machine performance, identify potential problems, and take corrective actions to prevent downtime.

2. Material Handling

intro paragraph

- Prepare and fill packaging materials, such as bottles, cans, or bags, according to specifications.

- Weigh, measure, and inspect products to ensure accuracy and quality.

- Load and unload products from machines, ensuring proper packaging and handling.

3. Quality Control

intro paragraph

- Inspect and monitor products for defects, such as leaks, spills, or broken seals.

- Ensure that products meet quality standards and specifications.

- Maintain records and documentation related to machine performance and product quality.

4. Maintenance and Troubleshooting

intro paragraph

- Perform routine maintenance and cleaning of packaging and filling machines.

- Identify and troubleshoot machine malfunctions, and take corrective actions to minimize downtime.

- Work with maintenance personnel to resolve complex technical issues.

Interview Tips

Preparing for an interview for a packaging/filling machine operator position requires a combination of technical knowledge, industry awareness, and preparation strategies.

1. Research the Company and Role

Thoroughly research the company’s website, industry publications, and social media pages to gain insights into their business, culture, and specific requirements for the role.

- Identify the company’s mission, values, and products or services.

- Learn about the specific responsibilities and expectations for the packaging/filling machine operator position.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that highlight your skills and experience.

- Describe your experience operating and troubleshooting packaging and filling machines.

- Explain how you ensure product quality and maintain machine efficiency.

- Share examples of how you have improved processes or resolved technical issues.

3. Quantify Your Accomplishments

Use numbers and metrics to quantify your accomplishments and demonstrate the impact of your work.

- For example, highlight how you reduced downtime by a certain percentage or improved product quality by implementing specific measures.

- Provide specific examples that showcase your ability to achieve results.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the position and company.

- Inquire about the company’s growth plans and future prospects.

- Ask about opportunities for training and professional development.

- Show your enthusiasm for the role and your potential contributions to the team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Packaging/Filling Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!