Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Packaging Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

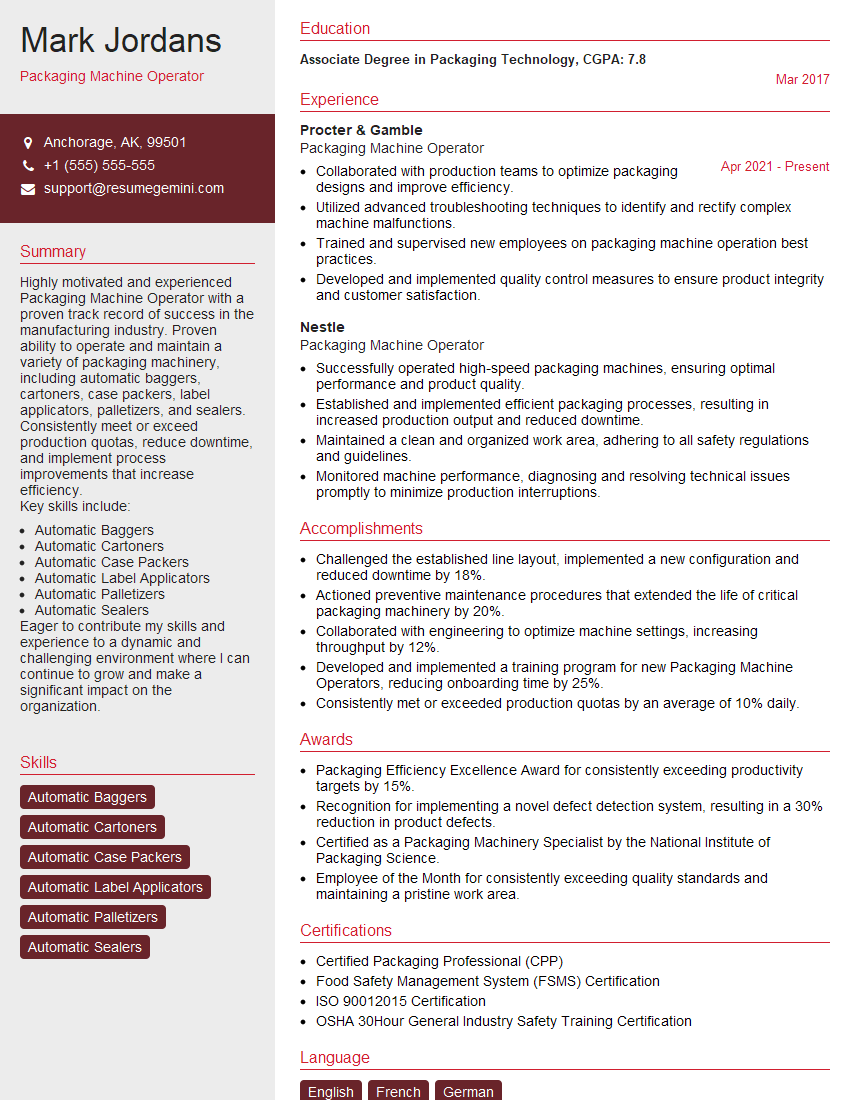

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Packaging Machine Operator

1. Explain the process of setting up and operating a packaging machine for a bag sealing job?

In setting up a packaging machine for bag sealing, I follow a meticulous process that ensures efficient operation:

- Pre-Setup: I start by reviewing the production order and verifying the required bag specifications, including size, material, and sealing requirements.

- Machine Setup: I mount the sealing jaws and adjust the settings according to the bag dimensions. I calibrate the temperature, pressure, and dwell time based on the material type and sealing parameters.

- Bag Loading: I load the bags into the machine’s hopper, ensuring proper alignment and orientation. I inspect the bags for any defects or damage that could affect sealing quality.

- Machine Operation: I initiate the sealing cycle, monitoring the machine’s progress and adjusting the settings as needed. I ensure the bags are sealed securely and meet the specified quality standards.

- Post-Operation: After completing the sealing operation, I inspect the sealed bags for any imperfections or leaks. I maintain accurate production records and document any issues encountered.

2. Describe the primary maintenance tasks you perform on packaging machines to ensure optimal performance?

Regular Maintenance

- Cleaning and Inspection: I regularly clean all machine components, removing dust, debris, and any product residue that could affect performance.

- Lubrication: I lubricate moving parts, such as bearings and chains, to minimize friction and wear, ensuring smooth operation.

- Tightening and Adjustments: I periodically check and tighten bolts, screws, and other fasteners to maintain proper alignment and prevent vibration.

Preventive Maintenance

- Filter Replacement: I replace air filters and oil filters to maintain optimal airflow and hydraulic system functionality.

- Belt Inspection and Replacement: I inspect belts for wear or damage and replace them as needed to prevent breakdowns.

- Electrical Inspection: I check electrical connections, wiring, and sensors to ensure proper functioning and prevent electrical issues.

3. How do you troubleshoot common packaging machine problems, such as jams and misalignment?

When troubleshooting common packaging machine problems, I follow a systematic process:

- Safety First: I always prioritize safety by isolating the machine, wearing appropriate PPE, and following lockout/tagout procedures.

- Problem Identification: I observe the machine’s operation, listen for unusual noises, and check for error messages to identify the root cause of the problem.

- Component Inspection: I examine the affected components, such as sensors, actuators, and mechanical parts, for any visible damage or wear.

- Parameter Adjustments: I verify and adjust machine settings, such as temperature, pressure, or timing, to ensure they align with the specified parameters.

- Testing and Validation: After implementing corrective actions, I test the machine and verify that the problem has been resolved. I document the troubleshooting steps and any changes made for future reference.

4. Discuss the quality control measures you implement to ensure the accuracy and consistency of packaging?

To ensure the accuracy and consistency of packaging, I implement a comprehensive quality control program that includes:

- Incoming Material Inspection: I inspect incoming packaging materials, such as bags, labels, and seals, to verify their quality and compliance with specifications.

- In-Process Checks: I conduct regular inspections during the packaging process to monitor product weight, dimensions, and sealing quality. I use measuring tools and gauges to ensure products meet the established standards.

- Finished Product Inspection: I inspect completed packages for any defects or inconsistencies, such as misaligned labels, damaged seals, or incorrect product count. I follow established quality control protocols to ensure products are packaged accurately and meet customer specifications.

5. How do you maintain a clean and organized work area, adhering to safety regulations and GMP standards?

Maintaining a clean and organized work area is crucial for both safety and productivity. I adhere to the following practices:

- Regular Cleaning: I regularly clean work surfaces, equipment, and tools to remove any product residue or debris that could accumulate.

- Waste Disposal: I properly dispose of waste materials, such as empty bags or damaged products, in designated containers.

- Material Organization: I organize packaging materials, tools, and equipment in designated areas to ensure easy access and prevent clutter.

- Safety Compliance: I follow established safety regulations, including wearing appropriate PPE and adhering to lockout/tagout procedures, to minimize risks.

6. How do you work effectively in a team environment, contributing to the overall success of the packaging operation?

Working effectively in a team environment is essential for a successful packaging operation. I contribute in the following ways:

- Communication: I actively communicate with team members to share information, coordinate efforts, and resolve issues promptly.

- Collaboration: I collaborate with colleagues to optimize processes, share expertise, and support each other during peak production times.

- Problem-Solving: I participate in team problem-solving sessions to identify and address challenges that impact packaging efficiency.

7. Describe your experience with using packaging software and automation systems to improve productivity?

I have experience using various packaging software and automation systems to enhance productivity:

- Production Scheduling Software: I utilize production scheduling software to plan and optimize packaging operations, ensuring efficient use of resources.

- Quality Control Software: I leverage quality control software to monitor and record packaging data, track trends, and identify potential issues.

- Automated Packaging Machines: I have experience operating automated packaging machines, such as bagging machines and case packers, to increase speed and accuracy.

8. How do you stay up-to-date with advancements in packaging technology and best practices?

I stay up-to-date with advancements in packaging technology and best practices through:

- Industry Publications: I read industry publications, journals, and news articles to stay informed about the latest packaging trends.

- Conferences and Trade Shows: I attend industry conferences and trade shows to learn about new products, technologies, and best practices.

- Online Resources: I utilize online resources, such as industry websites, forums, and training materials, to expand my knowledge.

9. How do you prioritize tasks and manage multiple responsibilities effectively?

I prioritize tasks and manage multiple responsibilities effectively by:

- Task Prioritization: I use a task management system to prioritize tasks based on urgency, importance, and deadlines.

- Time Management: I allocate time wisely, using techniques such as time blocking and the Eisenhower Matrix to maximize productivity.

- Delegation: When necessary, I delegate tasks to colleagues with the appropriate skills to ensure timely completion.

10. How do you handle working in a fast-paced and demanding work environment?

I thrive in fast-paced and demanding work environments by:

- Adaptability: I am flexible and adaptable, able to quickly adjust to changing priorities and production demands.

- Time Management: I prioritize tasks effectively and manage my time efficiently to meet tight deadlines.

- Stress Management: I employ stress management techniques, such as deep breathing and mindfulness, to maintain composure under pressure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Packaging Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Packaging Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Packaging Machine Operators are responsible for operating and maintaining packaging machines used to package products for distribution. They ensure that the machines are running smoothly and efficiently and that the products are packaged correctly. Key job responsibilities include:

1. Machine Operation

Operate packaging machines to package products according to specified requirements.

- Set up and adjust machines according to product specifications.

- Monitor machine operation and make adjustments as needed to ensure proper packaging.

2. Product Handling

Handle products carefully to prevent damage during packaging.

- Load and unload products from packaging machines.

- Inspect products for defects and remove any damaged items.

3. Quality Control

Ensure that packaged products meet quality standards.

- Check packaged products for defects, such as tears, leaks, or contamination.

- Reject products that do not meet quality standards.

4. Machine Maintenance

Perform basic maintenance on packaging machines.

- Clean and lubricate machines regularly.

- Identify and report any mechanical problems to supervisors.

Interview Tips

Preparing for an interview can be daunting, but following these tips can help you ace your interview for a Packaging Machine Operator position:

1. Research the Company and Position

Before the interview, research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a candidate.

- Visit the company’s website.

- Read reviews from current and former employees.

- Identify the key skills and experience required for the position.

2. Practice Your Answers

Take time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Common interview questions for Packaging Machine Operators include:

- Tell me about your experience operating packaging machines.

- How do you ensure that packaged products meet quality standards?

- What are your strengths and weaknesses as a Packaging Machine Operator?

3. Prepare Questions

Asking questions at the end of the interview shows that you are engaged and interested in the position.

- Some questions you could ask include:

- What are the biggest challenges facing the company right now?

- What are the opportunities for advancement within the company?

- What is the company’s culture like?

4. Dress Professionally

First impressions matter, so dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the workplace.

- Avoid wearing casual clothes, such as jeans, t-shirts, or sneakers.

- If you are unsure about what to wear, it is always better to err on the side of caution and dress more formally.

5. Be on Time

Punctuality is important, so make sure you arrive for your interview on time. This shows that you are respectful of the interviewer’s time.

- If you are running late, call or email the interviewer to let them know.

- Allow yourself plenty of time to get to the interview location, so you are not rushed or stressed.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Packaging Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.