Are you gearing up for a career in Packer-Fuser? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Packer-Fuser and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

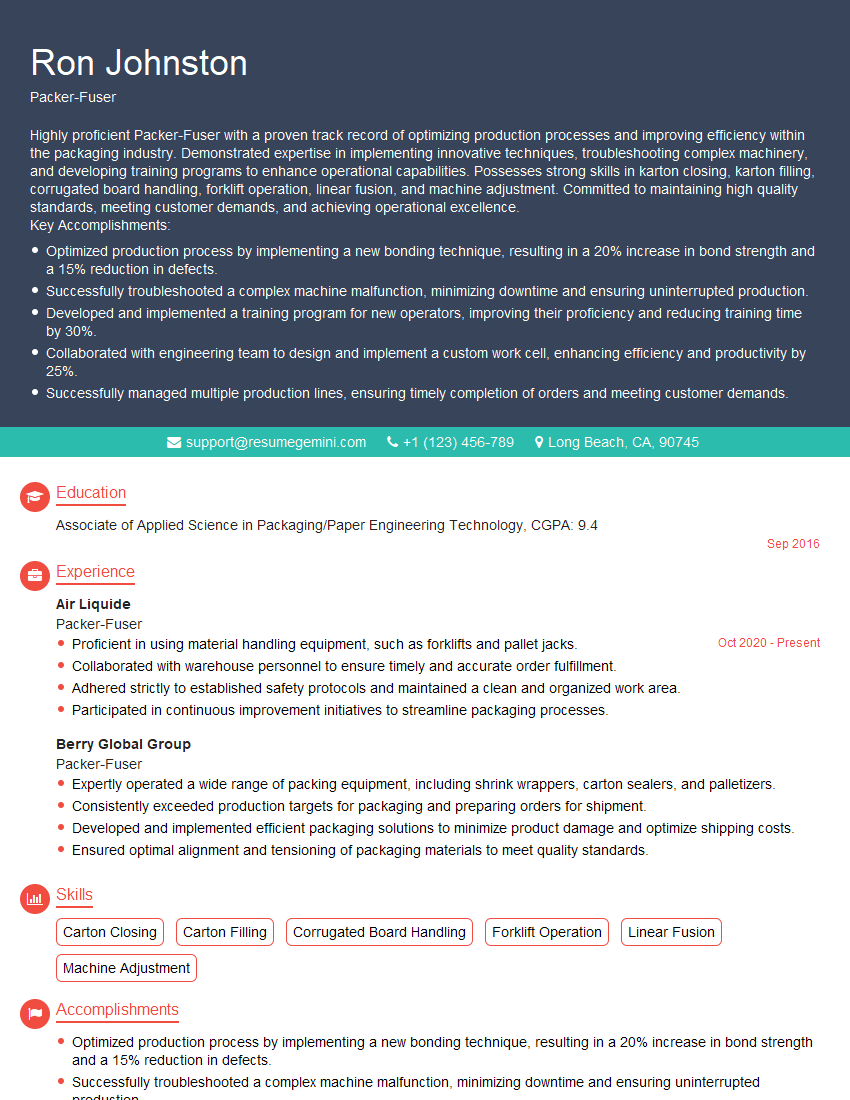

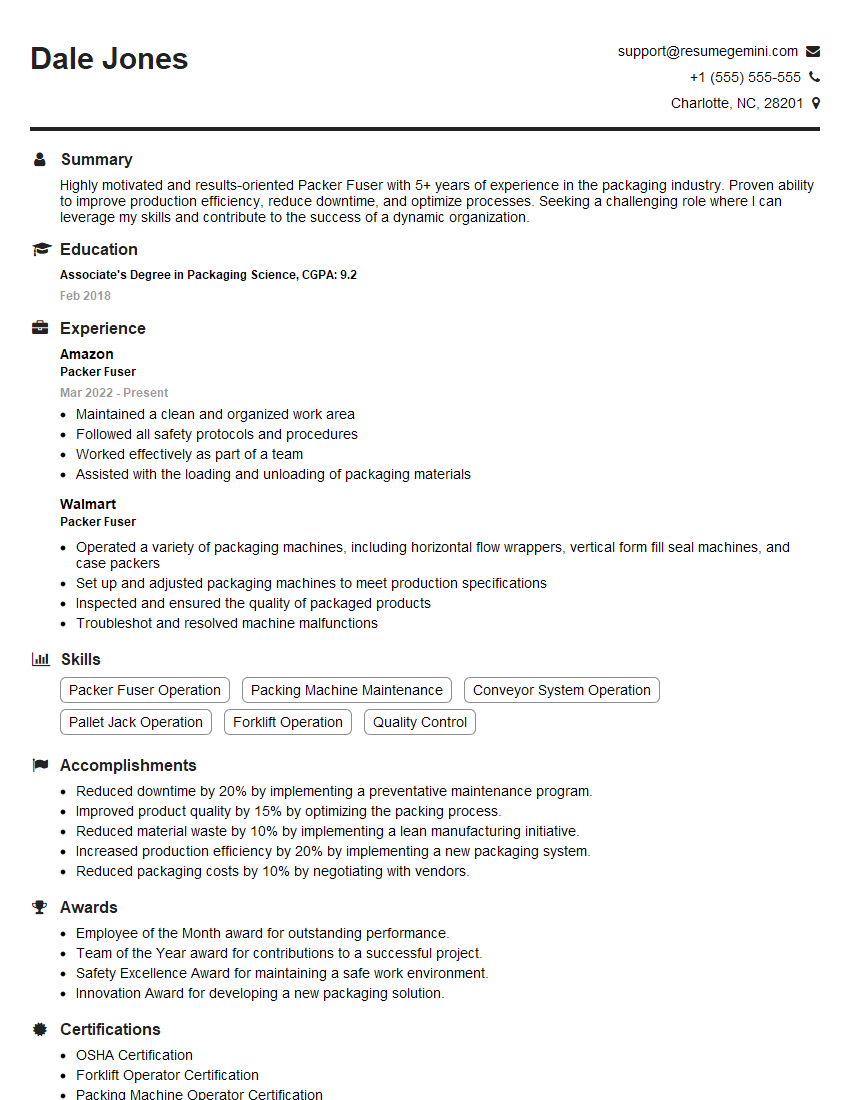

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Packer-Fuser

1. Explain the role of a packer-fuser and its key responsibilities?

A packer-fuser plays a critical role in the industrial packaging process, ensuring the proper packing, sealing, and fusing of corrugated cardboard boxes. The key responsibilities include:

- Operating packaging machines to fill, seal, and fuse corrugated boxes.

- Inspecting boxes for defects and ensuring they meet quality standards.

- Adjusting machine settings to optimize packing efficiency and box quality.

- Maintaining and troubleshooting packaging equipment to ensure smooth operations.

- Following safety protocols and adhering to company policies and procedures.

2. Describe the different types of packing machines used in industrial packaging?

Automatic packers

- Operate with minimal human intervention, utilizing robotic arms and sensors.

- High-speed and efficient, suitable for large-scale operations.

Semi-automatic packers

- Require some manual input, such as placing boxes and activating the packing process.

- Offer flexibility and customization options, suitable for smaller operations.

Manual packers

- Fully operated by hand, requiring physical strength and attention to detail.

- Suitable for small-scale operations or specialized packaging needs.

3. What are the essential skills and qualities required for a successful packer-fuser?

To excel as a packer-fuser, the following skills and qualities are essential:

- Strong physical strength and stamina for lifting and handling heavy boxes.

- Excellent hand-eye coordination and dexterity for precise packing and fusing operations.

- Attention to detail and a keen eye for identifying and correcting defects.

- Problem-solving abilities and technical aptitude for troubleshooting and maintaining equipment.

- Teamwork and communication skills for collaborating with colleagues.

4. Explain the importance of quality control in the packing process and how you ensure it?

Quality control in the packing process is crucial to ensure the integrity and safety of the packaged products. As a packer-fuser, I prioritize quality control by:

- Inspecting boxes thoroughly before and after packing for any damages or defects.

- Verifying the accuracy of product counts and ensuring proper packing materials.

- Adhering to established quality standards and protocols.

- Regularly monitoring and calibrating packaging equipment to maintain optimal performance.

- Reporting any quality issues or concerns promptly to supervisors or quality control personnel.

5. Describe the safety precautions and procedures that need to be followed when operating packing machines?

Safety is paramount in the operation of packing machines. I strictly adhere to the following safety precautions and procedures:

- Wearing appropriate safety gear, including protective clothing, gloves, and safety glasses.

- Inspecting machines before use and reporting any potential hazards or defects.

- Following lockout/tagout procedures when performing maintenance or repairs.

- Maintaining a clean and organized work environment.

- Being aware of potential tripping hazards and other safety risks.

6. How do you handle situations where you encounter problems or equipment malfunctions during the packing process?

When encountering problems or equipment malfunctions, I remain calm and follow a structured approach to resolve the issue:

- Identifying the problem accurately by observing symptoms and analyzing error messages.

- Consulting with colleagues or supervisors if necessary.

- Troubleshooting the issue by checking connections, settings, or potential blockages.

- Performing minor repairs or adjustments if authorized.

- Reporting the issue to maintenance personnel if unable to resolve it independently.

7. Explain how you prioritize your workload and manage multiple tasks effectively in a fast-paced packing environment?

In a fast-paced packing environment, I prioritize my workload by:

- Understanding the overall production goals and deadlines.

- Breaking down large orders into manageable tasks.

- Utilizing time-management techniques, such as the Pomodoro Technique.

- Communicating with colleagues to coordinate and delegate tasks.

- Avoiding distractions and staying focused on the most important tasks.

8. How do you ensure continuous improvement and maintain efficiency in your packing operations?

I am committed to continuous improvement and maintaining efficiency in my packing operations:

- Seeking feedback from colleagues, supervisors, and customers.

- Analyzing production data to identify areas for improvement.

- Exploring new technologies and techniques to enhance productivity.

- Participating in training and development programs to enhance my skills.

- Implementing process improvements to streamline operations and reduce waste.

9. Describe your experience with different types of packaging materials and how you select the appropriate ones for different products?

I have experience working with a wide range of packaging materials, including:

- Corrugated cardboard boxes

- Plastic bags and wraps

- Foam inserts and cushioning materials

- Wooden crates

- Specialty packaging for fragile or sensitive items

I select the appropriate packaging materials based on the following factors:

- Type and weight of product

- Transportation method and distance

- Environmental protection requirements

- Cost and availability

10. How do you stay updated with the latest industry trends and best practices in packing and fusing?

To stay updated with the latest industry trends and best practices, I:

- Attend trade shows and conferences

- Read industry publications and online resources

- Network with colleagues and peers

- Participate in professional development courses

- Seek out opportunities to learn about new technologies and techniques

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Packer-Fuser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Packer-Fuser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Packer-Fusers are responsible for operating high-volume packaging and fusing machines to produce finished products. They also perform a variety of other tasks, including:

1. Operating and maintaining packing machines

Packer-Fusers must be able to operate and maintain a variety of packing machines, including cartoners, case packers, and shrink wrappers. They must also be able to troubleshoot and repair minor machine problems.

- Loading and unloading products

- Adjusting machine settings

- Monitoring the production process

2. Fusing and sealing products

Packer-Fusers must be able to fuse and seal products using a variety of methods, including heat sealing, ultrasonic sealing, and pressure sealing. They must also be able to inspect finished products for defects.

- Selecting the appropriate sealing method

- Setting the machine settings

- Monitoring the sealing process

3. Packaging and handling products

Packer-Fusers must be able to package and handle products in a variety of ways, including boxing, crating, and shrink wrapping. They must also be able to label and barcode products.

- Selecting the appropriate packaging materials

- Preparing products for shipment

- Loading and unloading trucks

4. Maintaining a clean and safe work area

Packer-Fusers must be able to maintain a clean and safe work area. They must also be able to follow safety procedures and wear appropriate safety gear.

- Cleaning and disinfecting equipment

- Removing trash and debris

- Reporting any safety hazards

Interview Tips

Preparing for an interview for a Packer-Fuser position can be daunting, but by following these tips, you can increase your chances of success:

1. Research the company and the position

Before you go to the interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job.

- Visit the company website

- Read industry news and articles

- Talk to people who work for the company

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Use the STAR method to answer questions

- Be specific and provide examples

- Tailor your answers to the job description

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the job and that you respect their time.

- Wear business attire

- Be punctual

- Make eye contact and shake hands firmly

4. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic and positive about the job. Be sure to show your excitement for the opportunity to work for the company and to talk about your skills and experience.

- Smile and make eye contact

- Be confident and assertive

- Express your interest in the job

Next Step:

Now that you’re armed with the knowledge of Packer-Fuser interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Packer-Fuser positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini