Are you gearing up for a career in Packing Room Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Packing Room Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

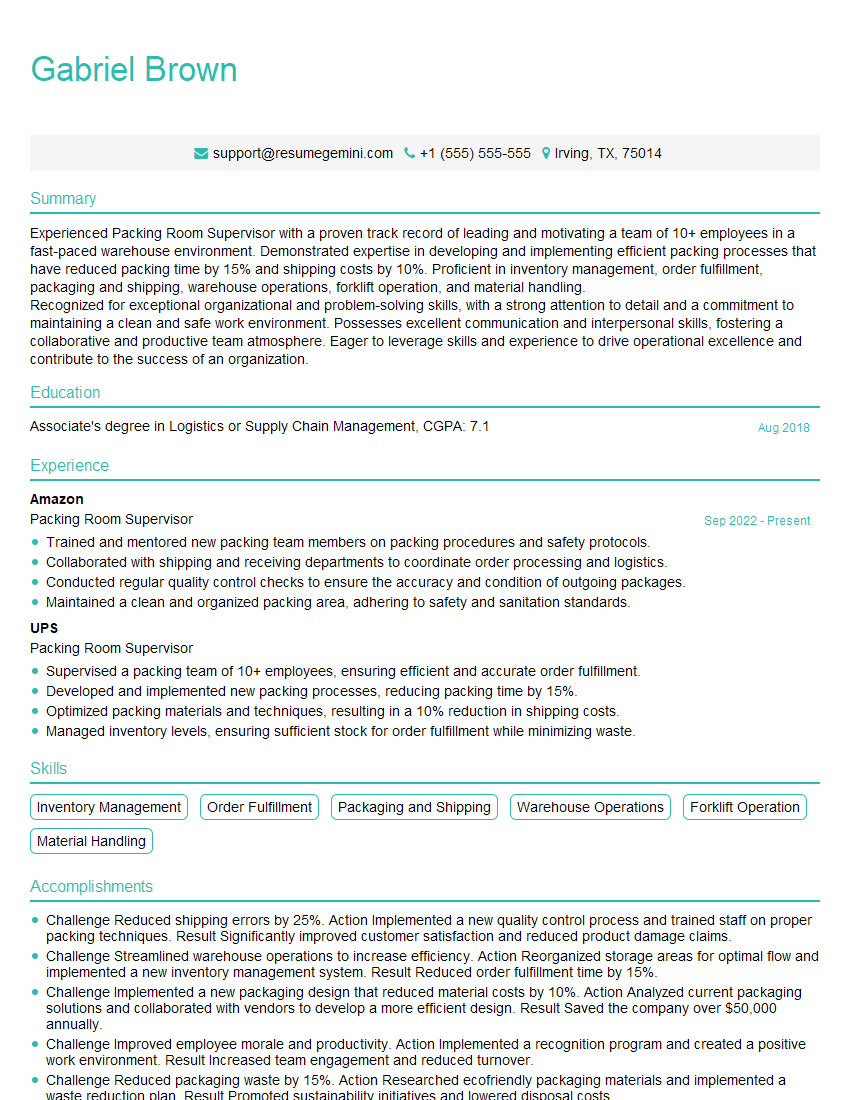

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Packing Room Supervisor

1. What are the key responsibilities of a Packing Room Supervisor in a manufacturing environment?

As a Packing Room Supervisor, my key responsibilities would encompass:

- Overseeing and coordinating all packing operations to ensure efficient and accurate packaging of products

- Supervising and managing a team of packers, ensuring proper training and adherence to quality standards

2. How would you approach implementing a new packaging system within the packing room?

Planning and Assessment

- Thoroughly evaluate the current packaging system, identifying areas for improvement and potential cost savings

- Research and explore various packaging options, considering factors such as material cost, sustainability, and product compatibility

Implementation

- Develop a comprehensive implementation plan, outlining the steps involved in transitioning to the new system

- Train staff on the new packaging techniques and ensure they understand the rationale behind the changes

Monitoring and Evaluation

- Monitor the performance of the new packaging system, tracking key metrics such as efficiency, cost, and customer satisfaction

- Make necessary adjustments to the system based on feedback and data analysis to optimize its effectiveness

3. What role does quality control play in the packing room, and how would you ensure its effectiveness?

Quality control plays a crucial role in the packing room. I would ensure its effectiveness through:

- Establishing clear quality standards and guidelines for packing operations

- Implementing a rigorous inspection process to identify and rectify any defects or errors in packaging

- Providing regular training to packers on quality control measures and best practices

- Empowering packers to report any quality issues or concerns promptly for timely resolution

4. What strategies would you employ to optimize packing productivity while maintaining quality standards?

To optimize packing productivity while maintaining quality standards, I would implement strategies such as:

- Streamlining packing processes through work simplification techniques and automation where possible

- Implementing standardized packing procedures to minimize errors and improve efficiency

- Providing continuous training to packers on proper packing techniques and equipment handling

- Establishing performance targets and providing incentives for meeting or exceeding productivity goals without compromising quality

5. How would you handle a situation where there is a shortage of packing materials, and production targets need to be met?

In the event of a shortage of packing materials, I would take the following steps:

- Assess the extent of the shortage and determine the impact on production targets

- Explore alternative packaging options that meet the required specifications and are readily available

- Communicate with suppliers to expedite the delivery of additional materials

- Prioritize packing operations to ensure that critical items are packed and shipped first

- Keep stakeholders informed about the situation and provide regular updates on the anticipated resolution time

6. What are the safety hazards commonly associated with packing operations, and how would you mitigate them?

Common safety hazards in packing operations include:

- Cuts and lacerations from sharp packaging materials

- Repetitive motion injuries from prolonged packing tasks

- Musculoskeletal injuries from lifting heavy items

Mitigation measures include:

- Providing proper personal protective equipment (PPE) such as gloves, safety glasses, and cut-resistant sleeves

- Implementing proper lifting techniques and providing mechanical aids for heavy lifting

- Encouraging regular breaks and job rotation to minimize repetitive motion injuries

- Conducting regular safety inspections and providing ongoing safety training to packers

7. How would you manage a team of packers with varying skill levels and experience?

To manage a team of packers with varying skill levels and experience, I would:

- Assess each packer’s skills and experience to identify areas for development

- Provide tailored training and support to help packers improve their skills and knowledge

- Delegate tasks based on each packer’s capabilities, ensuring that everyone is working at an appropriate level of challenge

- Foster a positive and supportive work environment where packers feel comfortable asking for help and sharing knowledge

- Recognize and reward packers for their contributions and progress, motivating them to excel

8. What inventory management techniques would you implement to ensure efficient packing operations?

To ensure efficient packing operations, I would implement inventory management techniques such as:

- Maintaining accurate and up-to-date inventory records to avoid stockouts and overstocking

- Using inventory tracking software to monitor stock levels and provide real-time visibility

- Implementing a first-in, first-out (FIFO) system to ensure that older inventory is used first

- Collaborating with suppliers to establish optimal inventory levels and lead times

- Conducting regular inventory audits to verify accuracy and identify any discrepancies

9. How would you approach training and developing your team of packers?

I believe in investing in my team’s development. My training approach would include:

- Conducting needs assessments to identify training gaps and areas for improvement

- Developing tailored training programs that address specific skills and knowledge requirements

- Providing a combination of on-the-job training, classroom instruction, and online learning resources

- Mentoring and coaching packers to support their growth and development

- Encouraging packers to participate in industry workshops and conferences to enhance their knowledge and skills

10. What performance metrics would you use to evaluate the effectiveness of the packing room operations?

To evaluate the effectiveness of packing room operations, I would monitor key performance metrics such as:

- Packing accuracy rate to measure the percentage of orders packed correctly

- Packing efficiency to assess the average time taken to pack an order

- Packing cost per unit to track the cost associated with packing operations

- Customer satisfaction ratings to gauge the quality of packing and its impact on customer satisfaction

- Inventory turnover ratio to measure the efficiency of inventory management practices

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Packing Room Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Packing Room Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Packing Room Supervisors play a pivotal role in ensuring efficient and accurate product packaging and preparation for shipment within a manufacturing or distribution environment.

1. Team Management and Supervision

Supervise and direct a team of packing operators, ensuring they adhere to packaging standards, meet production goals, and maintain a safe and organized work area.

- Provide clear instructions, training, and support to team members.

- Monitor performance, provide feedback, and develop strategies to enhance efficiency.

2. Packaging Quality Control

Establish and maintain packaging standards to ensure products are packed securely and meet customer specifications.

- Inspect incoming materials and packaging components for quality.

- Implement quality control measures throughout the packaging process.

3. Inventory and Materials Management

Manage and track inventory levels of packaging materials to avoid shortages and optimize costs.

- Coordinate with suppliers to ensure timely delivery of materials.

- Implement inventory control systems to monitor usage and minimize waste.

4. Equipment Maintenance and Safety

Ensure proper maintenance and operation of packaging equipment to minimize downtime and promote safety.

- Conduct regular inspections and implement preventive maintenance schedules.

- Enforce safety protocols and train team members on proper equipment handling.

Interview Tips

Interview preparation is crucial for maximizing your chances of success. Here are some tips to help you ace your interview for the Packing Room Supervisor position:

1. Research the Company and Position

Thoroughly research the company and their industry. Visit their website, read news articles, and gather information about their products, operations, and culture.

- Tailor your resume and cover letter to highlight specific skills and experiences that align with the job requirements.

- Prepare questions about the company, the position, and the industry to demonstrate your interest and enthusiasm.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses that showcase your qualifications.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your accomplishments.

- Practice your answers aloud or with a friend to improve your delivery and confidence.

3. Dress Professionally and Arrive Punctually

First impressions matter. Dress appropriately for the job and arrive at the interview on time to demonstrate your respect for the interviewer and the company.

- Pay attention to your personal hygiene and make sure your attire is clean and pressed.

- Allow yourself ample time to get to the interview location to avoid any potential delays.

4. Ask Thoughtful Questions

At the end of the interview, it’s your turn to ask questions. This is an excellent opportunity to demonstrate your interest in the position and the company.

- Ask questions about the company’s culture, growth plans, and future initiatives.

- Inquire about the specific responsibilities of the Packing Room Supervisor role and how you can contribute to the team.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Packing Room Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Packing Room Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.