Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pad Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

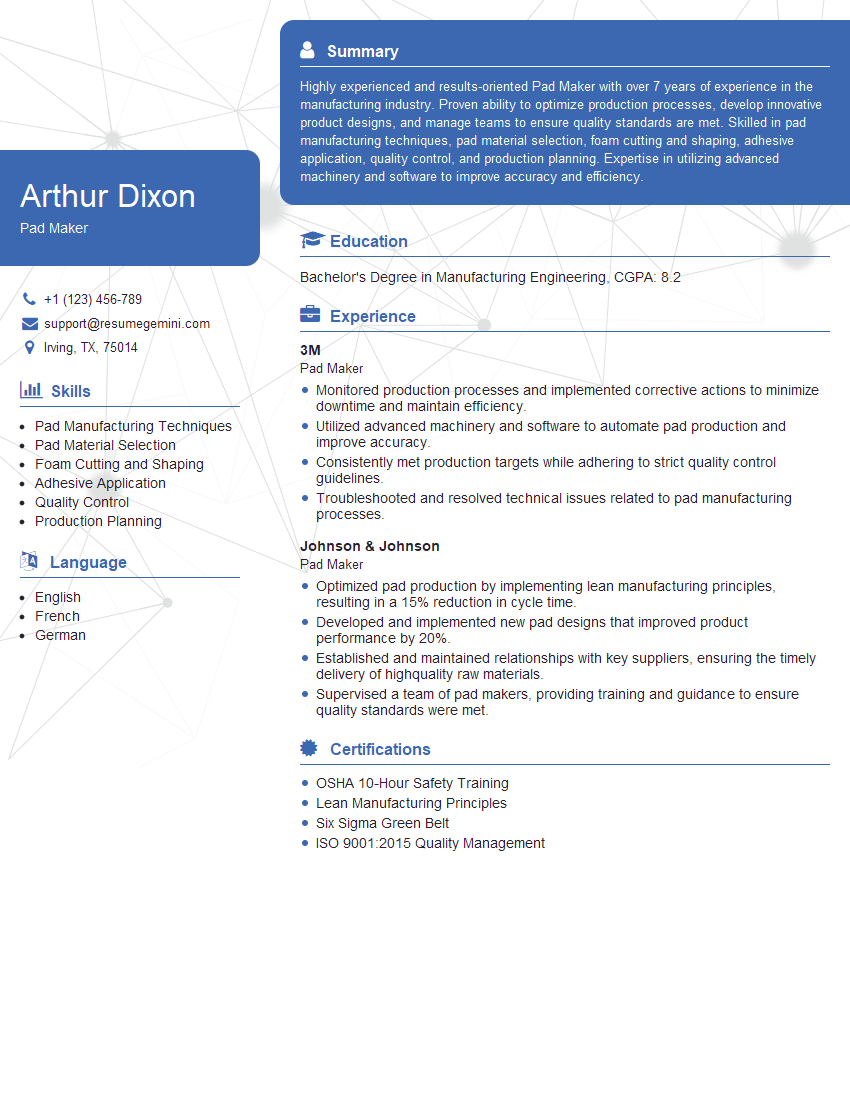

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pad Maker

1. What are the different types of pads used in manufacturing?

- Foam pads: Made of flexible polyurethane foam, used for cushioning, sound absorption, and sealing.

- Rubber pads: Resistant to wear and chemicals, used for vibration isolation, shock absorption, and as bumpers.

- Cork pads: Natural material with excellent vibration damping properties, used in sensitive equipment.

- Felt pads: Non-abrasive, used for protecting surfaces, reducing friction, and soundproofing.

- Plastic pads: Durable and versatile, used in a wide range of applications, including packaging, insulation, and electrical.

2. How do you determine the appropriate pad material for a specific application?

Consideration of the following factors:

- Purpose: The intended function of the pad (e.g., cushioning, sealing, shock absorption).

- Load: The weight or force the pad will be subjected to.

- Environment: The operating conditions the pad will encounter (e.g., temperature, humidity, chemicals).

- Cost: The budgetary constraints for the project.

Additional factors to consider:

- Density, hardness, and compressibility of the pad.

- Coefficient of friction.

- Thickness and shape.

3. What are the key quality control measures in pad manufacturing?

- Material inspection: Verifying the quality and consistency of raw materials.

- Process monitoring: Ensuring equipment is operating within specifications and maintaining proper process parameters.

- Dimensional measurements: Measuring the pads to ensure they meet the required dimensions and tolerances.

- Performance testing: Evaluating the pads’ performance in terms of cushioning, vibration isolation, or other intended functions.

- Visual inspection: Checking for defects, imperfections, or any abnormalities in the pads.

4. How do you troubleshoot common issues in pad manufacturing?

- Identifying the problem: Analyzing the symptoms and determining the root cause of the issue.

- Reviewing process parameters: Checking if there are any deviations from the established standards.

- Inspecting equipment: Examining machines and tools for any abnormalities or malfunctions.

- Testing raw materials: Verifying the quality and consistency of the materials used.

- Implementing corrective actions: Taking steps to address the root cause and prevent the issue from recurring.

5. What are the latest trends and advancements in pad manufacturing technology?

- 3D printing: Enables the production of complex and customized pads with enhanced flexibility and performance.

- Nanotechnology: Utilizes advanced materials and processes to create pads with improved properties, such as increased durability and reduced friction.

- Sustainable materials: Focus on using environmentally friendly materials and processes to reduce waste and minimize the environmental impact.

- IoT integration: Monitoring and controlling pad manufacturing processes remotely using sensors and data analytics.

- Automation: Implementing robotic systems and automation technologies to improve efficiency and reduce production costs.

6. What are the challenges faced in the pad manufacturing industry?

- Market competition: Pressure to deliver high-quality pads at competitive prices.

- Meeting customer demands: Adapting to changing customer requirements and meeting their expectations.

- Raw material availability: Ensuring a consistent supply of quality raw materials at affordable prices.

- Environmental regulations: Complying with regulations related to waste management and environmental sustainability.

- Technological advancements: Keeping up with the latest technological developments to remain competitive.

7. What are your strengths and weaknesses as a Pad Maker?

- Strengths:

- Thorough understanding of different pad materials, properties, and applications.

- Expertise in selecting and using appropriate materials for specific requirements.

- Excellent technical skills in pad design, production, and testing.

- Strong attention to detail and quality control.

- Proficient in troubleshooting and resolving production issues.

- Weaknesses:

- Limited experience in certain specialized pad manufacturing techniques.

- Need to improve knowledge of the latest industry trends and advancements.

- Working on developing stronger communication and interpersonal skills.

8. What are your career goals and aspirations as a Pad Maker?

- To become a highly skilled and experienced Pad Maker.

- Aspire to lead and manage a team of Pad Makers.

- Contribute to the development and innovation of new pad materials and technologies.

- Stay updated with the latest industry practices and advancements.

- Ultimately, I aim to establish myself as a respected expert in the pad manufacturing industry.

9. What are your expectations from this role and our company?

- Opportunities for professional development and growth.

- A challenging and rewarding work environment.

- Access to state-of-the-art equipment and technologies.

- Collaboration with experienced Pad Makers and industry professionals.

- A competitive salary and benefits package.

10. Do you have any questions for me about the role or our company?

- Could you provide more information about the company’s commitment to sustainability?

- I would like to know more about the company’s training and development programs for Pad Makers.

- Can you share some insights into the current projects and future plans of the company in the pad manufacturing industry?

- I am curious about the company’s approach to quality control and maintaining product consistency.

- Are there any opportunities for collaboration with other departments within the company?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pad Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pad Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pad Makers are responsible for producing high-quality pads as per the client’s requirements. They perform a variety of tasks to ensure that the pads meet the specifications and standards of the industry.

1. Setup and Operate Equipment

Pad Makers set up and operate machinery and equipment to produce pads, adhering to safety protocols. They perform regular maintenance and cleaning to ensure optimal equipment performance.

- Set up and adjust machines for different pad production specifications

- Operate machines safely and efficiently to produce pads

- Perform routine maintenance and cleaning of equipment

2. Prepare and Handle Raw Materials

Pad Makers are responsible for preparing and handling raw materials to produce pads. They ensure that the materials meet quality standards and are processed correctly.

- Prepare raw materials for production

- Inspect raw materials to ensure quality

- Store and handle raw materials properly

3. Monitor Quality

Pad Makers monitor the quality of pads produced to ensure that they meet the required specifications. They perform inspections and make adjustments as needed.

- Inspect pads to ensure quality and compliance with specifications

- Identify and correct defects in pads

- Make adjustments to equipment or processes to improve quality

4. Package and Ship Pads

Pad Makers package and ship pads to meet customer requirements. They ensure that the pads are properly packaged and shipped to the correct location.

- Package pads according to customer specifications

- Prepare shipping documents and arrange for shipment

- Ensure that pads are shipped to the correct destination

Interview Tips

Preparing for an interview for a Pad Maker position requires thorough research and practice. Here are some tips to help candidates ace the interview:

1. Research the Company

Familiarize yourself with the company’s products, services, and culture. This demonstrates your interest in the company and helps you tailor your answers to the interviewer’s questions.

2. Practice Answering Common Questions

Anticipate common interview questions and prepare your responses highlighting your relevant skills and experience. Practice your answers out loud to improve your delivery and confidence.

3. Highlight Your Technical Skills

Emphasize your technical skills and knowledge in pad production. Discuss your experience with machinery operation, quality control, and raw material handling. Provide specific examples to demonstrate your proficiency.

4. Showcase Your Attention to Detail

Pad Makers require meticulous attention to detail. Highlight your ability to follow instructions precisely, maintain a clean and organized work environment, and identify and correct defects effectively.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions about the company’s pad production process, quality standards, or any specific projects or initiatives.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pad Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.