Feeling lost in a sea of interview questions? Landed that dream interview for Padded Products Finisher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Padded Products Finisher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

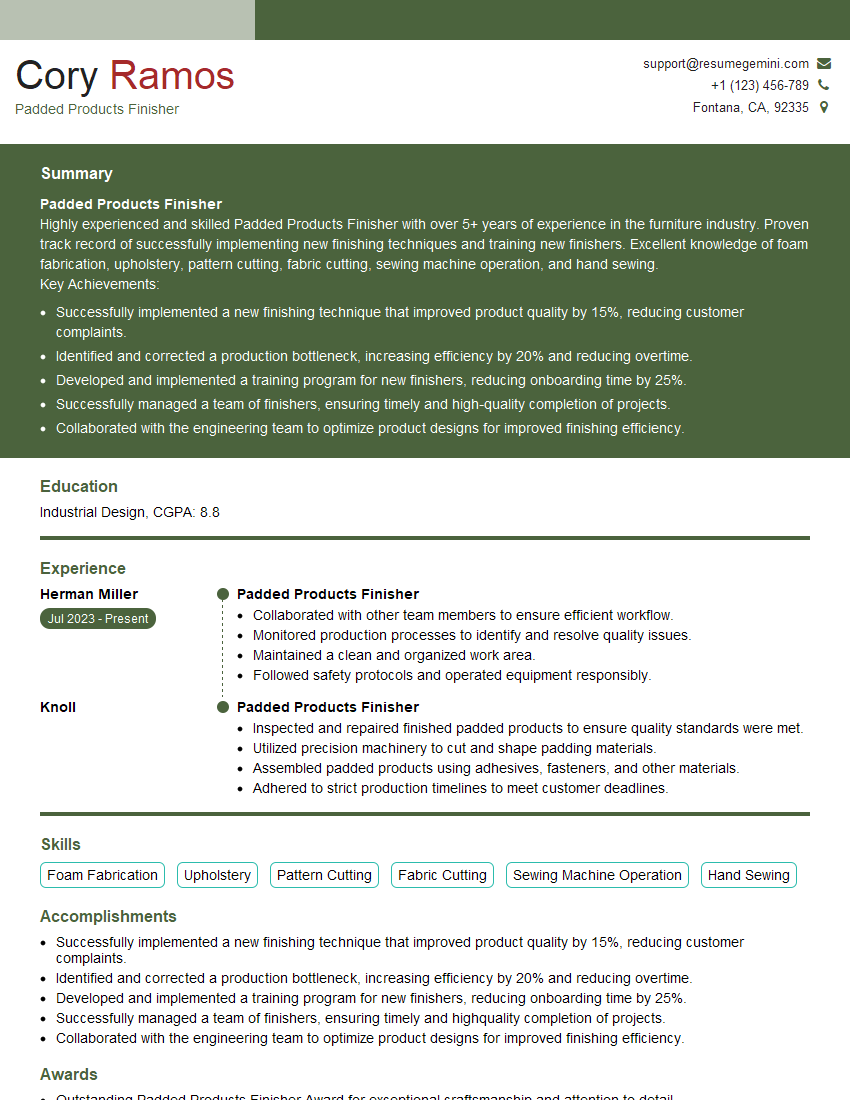

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Padded Products Finisher

1. What are the different types of padding materials used in the industry?

- Synthetic fibers (e.g., polyester, nylon, olefin)

- Natural fibers (e.g., cotton, wool)

- Foams (e.g., polyurethane, latex)

- Feathers and down

- Recycled materials (e.g., shredded textiles, plastic bottles)

2. What are the key factors to consider when selecting a padding material?

Factors to Consider:

- Purpose and application: The intended use of the padded product will dictate the required properties (e.g., durability, comfort, breathability)

- Cost: Different materials vary widely in cost, so it’s important to consider the budget constraints

- Density and thickness: The desired level of padding will determine the density and thickness of the material

- Fire resistance: In certain applications, fire resistance may be a crucial consideration

Additional Considerations:

- Allergies: Some materials may cause allergic reactions in certain individuals

- Environmental impact: The sustainability and recyclability of the material may be important factors

- Washability: If the padded product will be exposed to moisture or cleaning, washability becomes a key consideration

3. How do you determine the appropriate amount of padding for a given product?

- Product specifications: The design and intended use of the product will provide guidance on the amount of padding required

- Industry standards: Established industry standards can provide benchmarks for padding thickness and density

- Experience and testing: Practical experience and testing can help determine the optimal amount of padding for specific applications

- Customer feedback: Gathering feedback from customers who have used similar products can provide valuable insights

4. What techniques do you use to apply padding to different surfaces?

- Hand-stitching: Manually sewing the padding to the surface using needles and thread

- Machine-stitching: Using industrial sewing machines to attach the padding

- Gluing: Applying adhesives to bond the padding to the surface

- Vacuum forming: Molding the padding to the surface using a vacuum to create a tight fit

5. How do you ensure the quality and durability of the finished product?

- Quality materials: Using high-quality padding materials and fabrics

- Proper techniques: Following established industry practices and using appropriate techniques for applying padding

- Inspection and testing: Regularly inspecting products for defects and conducting tests to ensure durability and performance

- Customer feedback: Monitoring customer reviews and feedback to identify areas for improvement

6. What are some common problems encountered in padding and how do you resolve them?

- Uneven padding: Adjust the padding distribution or use additional techniques to distribute the padding evenly

- Loose or shifting padding: Use stronger adhesives, tighter stitching, or reinforce the padding’s attachment

- Lumpiness: Smooth out the padding by hand or use a vacuum former to achieve a smooth surface

- Durability issues: Use higher-quality materials, employ proper techniques, and conduct thorough testing to ensure durability

7. What are the latest trends and innovations in the padding industry?

- Eco-friendly materials: Growing demand for sustainable and recycled padding materials

- Advanced foams: Development of new foams with enhanced properties (e.g., breathability, fire resistance)

- Smart padding: Integration of sensors and technology into padding for added functionality

- Automated processes: Advancements in automation for increased efficiency and accuracy in padding

8. How do you stay updated on industry best practices and advancements?

- Trade shows and conferences: Attending industry events to learn about new products and technologies

- Industry publications: Reading trade magazines and online resources to stay informed about best practices

- Networking: Establishing connections with other professionals in the field to exchange knowledge and experience

- Continuing education: Participating in workshops, seminars, or online courses to enhance skills and stay current with industry trends

9. How do you prioritize safety and ergonomics in your work environment?

- Proper equipment: Using appropriate tools and equipment to minimize the risk of injury

- Safe work practices: Following established safety protocols and procedures

- Ergonomic workstation: Designing the workstation to reduce strain and promote comfort

- Training and awareness: Participating in safety training programs and maintaining awareness of potential hazards

10. What are your strengths and weaknesses as a Padded Products Finisher?

Strengths:

- Skilled in various padding techniques

- Attention to detail and quality

- Understanding of different padding materials

- Ability to work independently and as part of a team

- Committed to delivering high-quality products

Weaknesses:

- Limited experience with automated padding systems

- New to the industry, eager to learn and grow

- Time management

Note: It’s important to be honest and transparent about your weaknesses while highlighting your eagerness to improve.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Padded Products Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Padded Products Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Padded Products Finishers are responsible for the final finishing touches on padded products, such as mattresses, pillows, and cushions. They may work in a factory or a retail setting, and their duties may vary depending on the specific products they are working with.

1. Inspect and Trim Products

Padded Products Finishers inspect finished products to ensure that they meet quality standards. They may check for defects in the fabric, stitching, or padding. They may also trim excess fabric or thread to give the product a clean and finished look.

- Inspect finished products for defects in the fabric, stitching, or padding.

- Trim excess fabric or thread to give the product a clean and finished look.

2. Apply Finishing Touches

Padded Products Finishers may apply finishing touches to products, such as adding labels, tags, or decorative accents. They may also package the products for shipment or display.

- Add labels, tags, or decorative accents to products.

- Package the products for shipment or display.

3. Maintain Equipment

Padded Products Finishers may be responsible for maintaining the equipment they use, such as sewing machines, cutting machines, and packaging machines. They may clean and lubricate equipment, and make minor repairs.

- Clean and lubricate equipment.

- Make minor repairs to equipment.

4. Follow Safety Procedures

Padded Products Finishers must follow all safety procedures when working with machinery and materials. They may wear protective clothing and equipment, and they may be required to take safety training courses.

- Wear protective clothing and equipment.

- Take safety training courses.

Interview Tips

Preparing for an interview for a Padded Products Finisher position can help you make a good impression on the interviewer and increase your chances of getting the job. Here are some tips to help you prepare:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, goals, and the specific skills and experience they are looking for in a Padded Products Finisher.

- Visit the company’s website to learn about their history, products, and services.

- Read online reviews of the company to get a sense of the company culture and employee satisfaction.

- Review the job description carefully to identify the key skills and experience required for the position.

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked during an interview for a Padded Products Finisher position. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly during the interview.

- Tell me about your experience working with padded products.

- What are your strengths and weaknesses as a Padded Products Finisher?

- Why are you interested in this position?

- What are your salary expectations?

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Choose clothing that is clean, pressed, and appropriate for a business setting.

- Arrive for your interview on time, or even a few minutes early.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic and positive about the position and the company. Be sure to smile, make eye contact, and speak clearly and confidently during your interview. This will help you make a good impression and show the interviewer that you are genuinely interested in the job.

- Smile and make eye contact with the interviewer.

- Speak clearly and confidently.

- Share your enthusiasm for the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Padded Products Finisher interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.