Are you gearing up for a career in Padding Gluer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Padding Gluer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

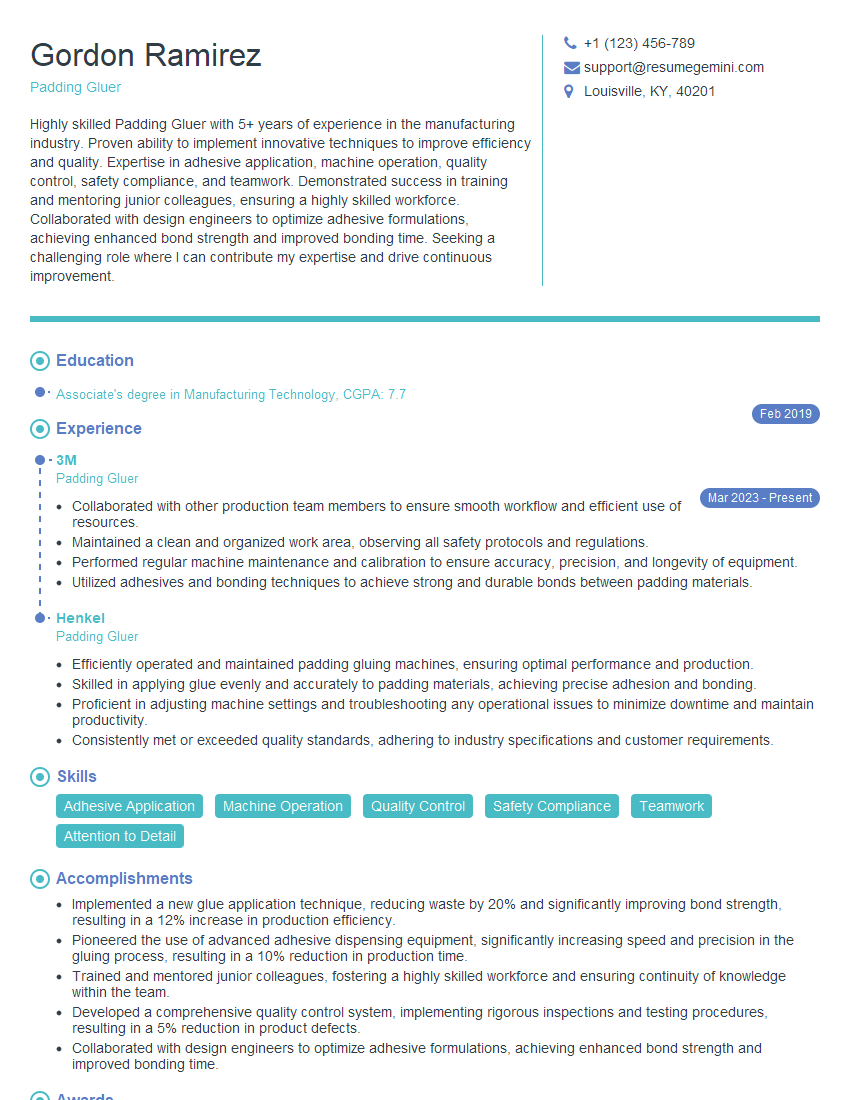

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Padding Gluer

1. Describe the typical responsibilities of a Padding Gluer in the corrugated box making industry?

The primary responsibilities of a Padding Gluer in the corrugated box making industry include:

- Operating and maintaining padding gluing machines to apply glue to the edges of corrugated board.

- Adjusting and calibrating machines to ensure proper glue application and adhesion.

- Monitoring the glue level and making necessary adjustments to maintain consistent quality.

- Troubleshooting and resolving any machine malfunctions or production issues.

- Ensuring adherence to safety protocols and maintaining a clean and organized work area.

2. What are the key factors to consider when selecting the appropriate glue for padding gluing?

When selecting the appropriate glue for padding gluing, several key factors should be considered:

Viscosity and flow characteristics:

- The glue should have the right viscosity to provide sufficient spreadability and penetration into the flutes of the corrugated board.

Adhesion and bond strength:

- The glue should provide strong and durable adhesion between the corrugated board layers.

Drying time and open time:

- The glue should have an appropriate drying time to allow for proper adhesion while also providing sufficient open time for assembly.

Environmental considerations:

- The glue should meet environmental regulations and be safe for use in industrial settings.

- Water-based glues are often preferred for their environmental friendliness and reduced emissions.

3. What are the common problems encountered during padding gluing and how can they be resolved?

Common problems encountered during padding gluing include:

- Poor adhesion: Can be caused by insufficient glue application, improper adhesive selection, or contamination of the board surface. Solutions include adjusting glue application settings, selecting a more suitable adhesive, or cleaning the board surface.

- Glue bleed-through: Occurs when excessive glue penetrates through the flutes of the board. It can be prevented by using the correct glue viscosity, adjusting glue application settings, or adding a pre-coat to the board.

- Washboarding: Distortion of the board due to uneven glue application. It can be addressed by adjusting machine settings, ensuring proper glue distribution, and using a more flexible adhesive.

- Machine malfunctions: Prompt troubleshooting and repair are crucial to minimize downtime and ensure efficient operation.

4. Describe the safety precautions that must be taken when working with padding gluing machines.

Essential safety precautions for working with padding gluing machines include:

- Wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and earplugs.

- Following proper machine operation procedures and avoiding unauthorized access.

- Keeping the work area clean and free from tripping hazards.

- Handling chemicals and adhesives with care, including proper storage and disposal.

- Being aware of potential hazards such as electrical shocks, moving parts, and high-temperature surfaces.

5. Explain how you would maintain and calibrate a padding gluing machine.

Regular maintenance and calibration are crucial for optimal machine performance. Here’s how I would approach this task:

Maintenance:

- Cleaning the machine regularly to remove glue residue and debris.

- Inspecting and replacing worn or damaged parts as needed.

- Lubricating moving parts to ensure smooth operation.

Calibration:

- Using precision instruments to adjust machine settings.

- Ensuring accurate glue application by calibrating the glue applicator and flow rate.

- Testing machine performance with sample materials to verify proper operation.

6. What quality control measures would you implement to ensure the production of high-quality padded boards?

To ensure the production of high-quality padded boards, I would implement the following quality control measures:

- Inspecting incoming materials: Verifying the quality and specifications of corrugated board and glue.

- Monitoring machine settings: Regularly checking and adjusting machine settings to maintain consistent glue application.

- Sampling and testing: Conducting random sampling of padded boards to assess adhesion strength, glue penetration, and overall appearance.

- Process monitoring: Observing and recording key production parameters such as glue temperature, pressure, and drying time.

- Corrective action: Taking prompt action to address any deviations from quality standards and implementing corrective measures.

7. How would you optimize the efficiency of a padding gluing line?

To optimize the efficiency of a padding gluing line, I would focus on the following strategies:

- Preventive maintenance: Regularly servicing and maintaining machines to avoid unexpected breakdowns.

- Workflow optimization: Streamlining the production process to reduce bottlenecks and improve throughput.

- Operator training: Providing comprehensive training to operators to ensure proper machine operation and handling.

- Material handling: Implementing efficient material handling systems to minimize downtime and improve productivity.

- Continuous improvement: Regularly evaluating and identifying areas for improvement to enhance overall efficiency.

8. Describe your experience in troubleshooting padding gluing machine issues.

Throughout my experience as a Padding Gluer, I have encountered and successfully resolved various machine issues, including:

- Glue application problems: Identified and addressed issues such as uneven glue distribution, excessive glue bleed-through, and poor adhesion.

- Mechanical malfunctions: Troubleshooted and repaired mechanical issues such as motor failures, conveyor problems, and sensor malfunctions.

- Electrical faults: Diagnosed and resolved electrical issues such as short circuits, loose connections, and faulty components.

- Production quality issues: Analyzed and identified the root causes of quality problems such as washboarding, delamination, and poor bonding.

9. How do you stay up-to-date with the latest trends and technologies in the corrugated box making industry?

To stay up-to-date with the latest trends and technologies in the corrugated box making industry, I actively engage in the following activities:

- Industry events: Attending conferences, trade shows, and workshops to learn about new technologies and best practices.

- Technical publications: Reading industry magazines, journals, and technical articles to stay informed about advancements.

- Online resources: Utilizing online platforms such as industry forums and webinars to connect with experts and exchange knowledge.

- Networking: Building relationships with colleagues, suppliers, and equipment manufacturers to stay abreast of industry developments.

10. Why are you interested in working as a Padding Gluer in our company?

I am eager to join your company as a Padding Gluer because:

- Reputation and expertise: Your company is renowned in the industry for its commitment to quality and innovation, which aligns with my professional goals.

- Growth opportunities: I believe that your company provides a supportive environment for professional development and advancement.

- Teamwork and collaboration: I am excited about the prospect of contributing to a collaborative and supportive team.

- Commitment to sustainability: Your company’s focus on sustainability resonates with my personal values.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Padding Gluer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Padding Gluer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Padding Gluers work in printing and publishing industries, and are responsible for operating machines that apply glue to the spine of books, magazines, and other printed materials.

1. Machine Operation

Padding Gluer must have the ability to operate padding gluing machines efficiently and safely.

- Set up and calibrate the machine according to the job specifications.

- Load the machine with printed materials and operate the machine to apply glue to the spine.

- Monitor the machine’s operation and make adjustments as needed.

2. Quality Control

Padding Gluer must be able to inspect the finished products for quality and accuracy.

- Inspect the glued materials for defects, such as uneven glue application or misalignment.

- Make adjustments to the machine or the process as needed to ensure that the finished products meet quality standards.

3. Maintenance and Repair

Padding Gluer may be required to perform basic maintenance and repairs on the machine.

- Clean and lubricate the machine regularly.

- Troubleshoot and repair minor problems with the machine.

- Report major problems to the supervisor.

4. Safety

Padding Gluer must be aware of the safety hazards associated with the job and take appropriate precautions.

- Wear appropriate safety gear, such as gloves and safety glasses.

- Follow all safety procedures and regulations.

- Report any unsafe conditions to the supervisor.

Interview Tips

Interviewing for a Padding Gluer position can be competitive. However, by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Before your interview, take some time to research the company and the specific position you are applying for.

- Visit the company’s website to learn about their history, mission, and products or services.

- Read the job description carefully and identify the key skills and qualifications that the employer is looking for.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”.

- Take some time to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Be sure to tailor your answers to the specific position you are applying for.

3. Highlight Your Relevant Skills and Experience

In your interview, be sure to highlight your relevant skills and experience.

- If you have previous experience as a Padding Gluer, be sure to describe your responsibilities and accomplishments.

- If you do not have direct experience, you can highlight other skills and experience that are relevant to the position, such as your attention to detail, your ability to work independently, and your strong work ethic.

4. Be Prepared to Talk About Safety

Safety is an important aspect of the Padding Gluer position. In your interview, be prepared to talk about your safety knowledge and experience.

- Describe your understanding of the safety hazards associated with the job.

- Explain the safety procedures that you would follow to protect yourself and others.

5. Be Enthusiastic and Positive

Employers are looking for candidates who are enthusiastic and positive about the job. In your interview, be sure to convey your excitement about the opportunity to work as a Padding Gluer.

- Smile, make eye contact, and speak clearly.

- Be confident in your abilities and your ability to succeed in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Padding Gluer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.