Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Padding Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Padding Machine Operator so you can tailor your answers to impress potential employers.

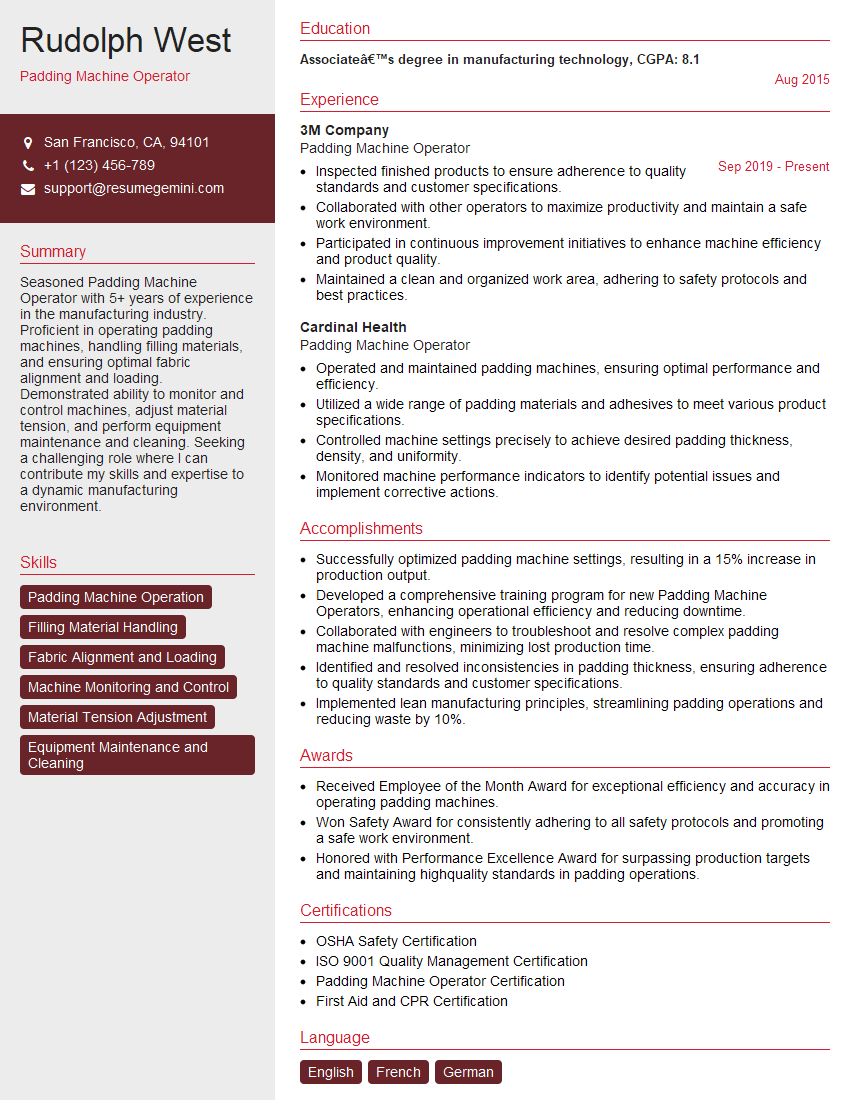

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Padding Machine Operator

1. What are the key responsibilities of a Padding Machine Operator?

My key responsibilities as a Padding Machine Operator would include:

- Operating and monitoring padding machines to apply padding material to fabrics

- Setting up and adjusting machines according to production requirements

- Inspecting padding quality and making adjustments as needed

- Maintaining a clean and safe work area

- Following safety protocols and operating procedures

2. How do you ensure the quality of the padding process?

Monitoring Process Parameters

- Regularly check machine settings, including temperature, pressure, and speed

- Monitor fabric tension and padding thickness to ensure consistency

Visual Inspection

- Inspect padded fabric for defects such as uneven padding, wrinkles, or tears

- Use specialized tools and techniques to assess padding quality

Testing and Analysis

- Conduct tests to determine the absorption, resilience, and other properties of the padding

- Analyze test results and make adjustments to the padding process as needed

3. What are some of the challenges you have faced as a Padding Machine Operator and how did you overcome them?

One challenge I encountered was maintaining consistent padding quality when working with different fabric types. To overcome this, I:

- Adjusted machine settings based on fabric properties, such as thickness and absorbency

- Conducted trial runs to determine the optimal settings for each fabric type

- Collaborated with quality control personnel to establish and maintain quality standards

4. How do you stay up-to-date with the latest advancements in padding technology?

- Attend industry trade shows and conferences

- Read technical journals and articles

- Participate in training programs offered by equipment manufacturers

- Network with other Padding Machine Operators and industry professionals

5. What are the safety precautions that must be followed when operating a padding machine?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator

- Keep hands and loose clothing away from moving parts

- Never operate the machine with guards or covers removed

- Follow established lockout/tagout procedures

- Report any safety concerns or malfunctions to a supervisor immediately

6. How do you troubleshoot common problems that may arise with padding machines?

- Identify the problem and its potential causes

- Refer to maintenance manuals and technical documentation

- Perform basic troubleshooting steps, such as checking electrical connections and adjusting settings

- Contact the equipment manufacturer or a qualified technician for more complex issues

7. How do you handle working in a fast-paced manufacturing environment?

In a fast-paced manufacturing environment, I:

- Prioritize tasks and manage my time effectively

- Communicate clearly and efficiently with colleagues and supervisors

- Stay focused and maintain a high level of accuracy

- Adapt quickly to changing production demands

- Seek support from teammates when needed

8. What is your experience with different types of padding materials?

I have experience working with a variety of padding materials, including:

- Polyester

- Foam

- Cotton

- Non-woven materials

I am familiar with the properties and applications of each material and can adjust the padding process accordingly.

9. How do you maintain a clean and organized work area?

- Regularly clean and disinfect the padding machine and surrounding area

- Dispose of waste materials properly

- Keep tools and equipment organized and accessible

- Follow established housekeeping procedures

- Report any spills or leaks promptly

10. Why are you interested in working as a Padding Machine Operator for our company?

I am eager to join your company as a Padding Machine Operator because:

- I am passionate about manufacturing and have a strong understanding of padding processes

- I am committed to delivering high-quality products and maintaining a safe work environment

- I am confident that my skills and experience would be a valuable asset to your team

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Padding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Padding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Padding Machine Operators are responsible for operating and maintaining padding machines that add a layer of padding or cushioning to various materials.

1. Machine Operation and Maintenance

Operate padding machines to apply padding to materials such as textiles, leather, and foam.

- Set up and adjust machines according to production specifications

- Monitor machine operations to ensure proper functioning and quality of the padded materials

- Perform regular maintenance tasks, such as cleaning and lubricating machines

2. Material Handling

Load and unload materials to and from the padding machine.

- Handle materials with care to prevent damage

- Maintain a clean and organized work area

- Dispose of waste materials properly

3. Quality Control

Inspect padded materials to ensure they meet quality standards.

- Identify and correct any defects

- Maintain records of quality checks

- Report any quality concerns to supervisors

4. Safety and Compliance

Follow established safety procedures and regulations.

- Wear appropriate personal protective equipment (PPE)

- Operate machines safely and avoid accidents

- Comply with environmental regulations

Interview Tips

Preparing for a Padding Machine Operator interview requires a combination of technical knowledge, attention to detail, and a commitment to safety.

1. Research the Company and Position

Learn about the company’s products, services, and industry standing.

- Review the job description thoroughly to understand the specific requirements of the role

- Check the company website and social media pages for insights into their culture and values

2. Highlight Relevant Skills and Experience

Emphasize your experience operating padding machines or similar equipment.

- Provide specific examples of your ability to maintain and troubleshoot machines

- Discuss your experience in handling and inspecting materials

- Mention any certifications or training you have that are relevant to the position

3. Demonstrate Attention to Detail and Accuracy

Convey your commitment to producing high-quality work and maintaining accuracy.

- Describe your experience in following quality control procedures

- Explain how you pay attention to details and identify potential problems

- Share examples of how you ensure the accuracy of your work

4. Emphasize Safety and Compliance

Show that you understand the importance of adhering to safety regulations and operating equipment responsibly.

- Discuss your experience with safety protocols in a manufacturing environment

- Explain how you follow established procedures and use proper PPE

- Mention any training or certifications you have related to safety and compliance

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Padding Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.