Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Paint Formulator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Paint Formulator so you can tailor your answers to impress potential employers.

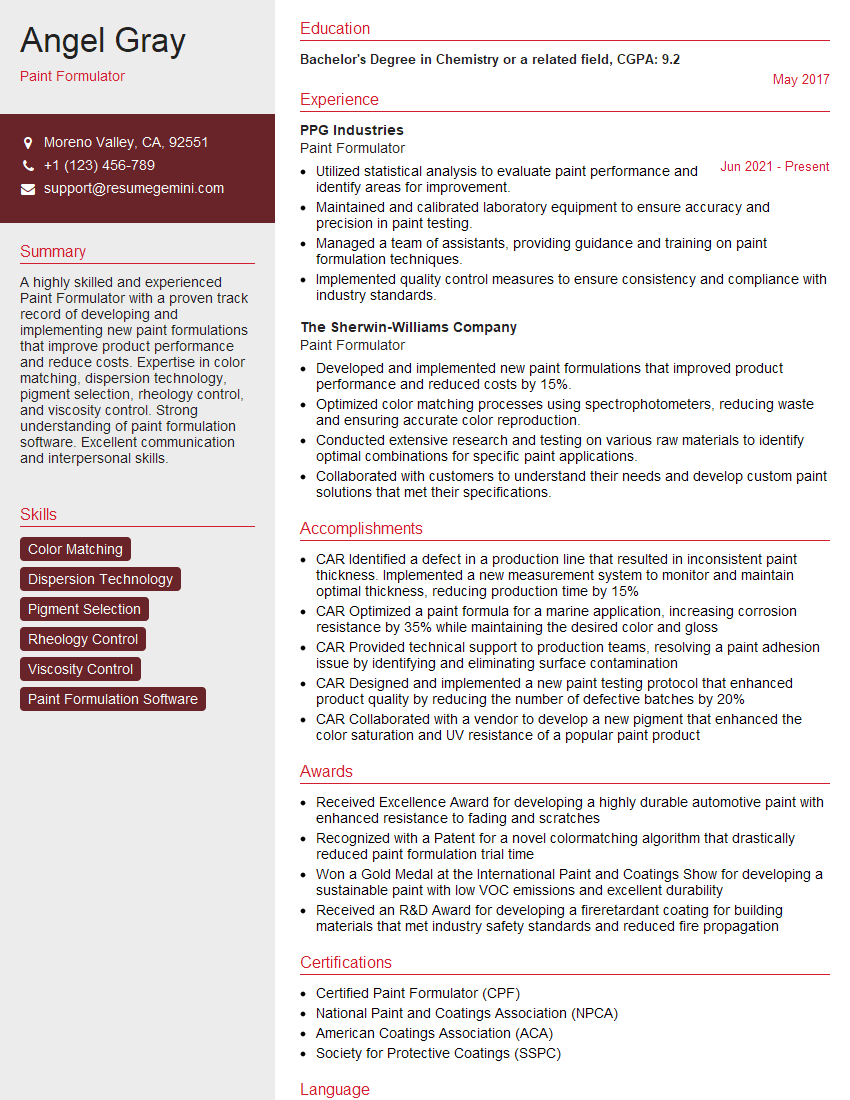

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Paint Formulator

1. Discuss the key factors to consider when formulating a paint for a specific application?

- Substrate type: The type of surface the paint will be applied to, such as wood, metal, or plastic, will determine the appropriate formulation.

- Environmental conditions: The paint must be able to withstand the specific environmental conditions it will be exposed to, such as temperature, humidity, and UV radiation.

- Desired performance characteristics: The paint should meet the desired performance characteristics, such as durability, color retention, and resistance to chemicals or abrasion.

- Cost and availability: The cost and availability of the raw materials used in the formulation should be considered.

- Regulatory requirements: The paint must meet any applicable regulatory requirements, such as those governing VOC emissions or hazardous substances.

2. Describe the different types of paint resins and their properties?

Solvent-based resins

- Alkyd resins: Durable, high-gloss, and resistant to chemicals and abrasion.

- Acrylic resins: Fast-drying, water-based, and offer good color retention and durability.

- Epoxy resins: High-performance resins with excellent adhesion, chemical resistance, and durability.

Water-based resins

- Acrylic resins: Similar to solvent-based acrylic resins, but more environmentally friendly.

- Polyurethane resins: Offer good durability, flexibility, and resistance to water and chemicals.

- Vinyl acetate resins: Water-reducible, fast-drying, and provide good adhesion.

3. How do you determine the appropriate pigment loading for a paint formulation?

- Desired color and opacity: The pigment loading will determine the intensity and hiding power of the paint.

- Binder type and amount: The binder will hold the pigment particles together and affect the overall film properties.

- Particle size and shape: Smaller pigment particles provide better hiding but may require higher loading.

- Rheology modifiers: These additives can adjust the flow and application properties of the paint, allowing for higher pigment loading.

- Cost and availability: The cost and availability of the pigments should be considered.

4. Explain the role of solvents in paint formulations?

- Dissolving resins: Solvents dissolve the resin to form the liquid vehicle of the paint.

- Adjusting viscosity: Solvents can control the viscosity of the paint, making it easier to apply.

- Improving flow and leveling: Solvents help the paint flow smoothly and level out after application.

- Evaporation rate: The evaporation rate of the solvent affects the drying time and film formation.

- Cost and environmental impact: The cost and environmental impact of the solvents should be considered.

5. Describe the different methods used to test the performance of paint films?

- Adhesion testing: Determines the strength of the bond between the paint film and the substrate.

- Gloss measurement: Measures the level of reflection from the paint film, indicating its shininess.

- Color measurement: Assesses the color accuracy and consistency of the paint film.

- Durability testing: Evaluates the paint film’s resistance to weathering, chemicals, and abrasion.

- Rheology testing: Measures the flow and application properties of the paint.

6. What are the common defects that can occur in paint films and how can they be prevented?

- Blistering: Caused by moisture trapped beneath the paint film, which can be prevented by proper surface preparation and using breathable coatings.

- Cracking: Occurs due to excessive stress on the paint film, which can be reduced by using flexible binders and avoiding thick applications.

- Peeling: When the paint film loses adhesion to the substrate, which can be prevented by ensuring proper surface preparation and using compatible primers.

- Fading: Caused by the degradation of pigments by UV radiation, which can be minimized by using UV-resistant pigments and coatings.

- Yellowing: Occurs due to the oxidation of oils in the paint film, which can be prevented by using non-yellowing resins and additives.

7. Discuss the latest trends in paint formulation and their impact on the industry?

- Sustainability: Emphasis on reducing environmental impact through the use of eco-friendly raw materials and low-VOC formulations.

- Advanced coatings: Development of coatings with enhanced properties, such as self-cleaning, antimicrobial, and anti-graffiti.

- Digitalization: Use of digital tools for formulation optimization, color matching, and process control.

- Nanotechnology: Incorporation of nanoparticles to improve film properties and functionality.

- Personalized coatings: Tailoring paint formulations to meet specific customer needs and applications.

8. How do you stay up-to-date with new developments in paint technology?

- Industry conferences and exhibitions: Attending industry events to learn about new products and technologies.

- Technical publications and journals: Reading trade magazines, scientific papers, and research reports.

- Online resources: Utilizing online databases, industry websites, and social media platforms.

- Networking: Connecting with other professionals in the field to exchange ideas and stay informed.

- Continuing education: Pursuing seminars, workshops, and online courses to enhance knowledge and skills.

9. Describe a challenging paint formulation project you worked on and how you overcame the challenges?

- Project description: Provide a brief overview of the project and its objectives.

- Challenges encountered: Explain the specific technical challenges you faced during the formulation process.

- Problem-solving approach: Describe the steps you took to research, analyze, and overcome the challenges.

- Outcome: Explain how you achieved the desired results and met the project requirements.

10. How do you ensure the quality and consistency of paint products?

- Raw material testing: Verifying the quality and purity of incoming raw materials.

- Process control: Monitoring and adjusting the manufacturing process to maintain consistent production parameters.

- In-process testing: Conducting quality checks during the manufacturing process to identify any deviations.

- Finished product testing: Testing the final paint products to ensure they meet performance specifications.

- Quality management system: Implementing a comprehensive quality management system to track and improve quality processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Paint Formulator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Paint Formulator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Paint Formulators are responsible for developing and testing new paint formulas, as well as improving existing ones. They work closely with chemists, engineers, and other scientists to ensure that the paint meets the desired specifications.

1. Research and Development

Paint Formulators conduct research on new materials and technologies to improve the performance of paint. They also develop new paint formulas based on these findings.

- Conduct research on new materials and technologies

- Develop new paint formulas based on research findings

2. Testing and Evaluation

Paint Formulators test and evaluate paint formulas to ensure that they meet the desired specifications. They also conduct quality control tests to ensure that the paint is consistent from batch to batch.

- Test and evaluate paint formulas

- Conduct quality control tests

3. Production Support

Paint Formulators provide technical support to the production team. They also help to troubleshoot any problems that may arise during production.

- Provide technical support to the production team

- Help to troubleshoot problems

4. Customer Support

Paint Formulators provide customer support to answer questions about the paint and its application. They also help to resolve any complaints that may arise.

- Provide customer support

- Answer questions about the paint

- Resolve complaints

Interview Tips

Here are some tips to help you ace your interview for a Paint Formulator position:

1. Research the Company and the Position

Before your interview, take the time to research the company and the specific position you’re applying for. This will help you understand the company’s culture and the specific needs of the role.

- Visit the company’s website

- Read about the company’s products and services

- Research the specific position you’re applying for

2. Prepare for Common Interview Questions

There are a number of common interview questions that you’re likely to be asked in an interview for a Paint Formulator position. Be prepared to answer these questions clearly and concisely.

- Tell me about your experience in paint formulation.

- What are your strengths and weaknesses as a Paint Formulator?

- Why are you interested in this position?

3. Be Professional and Enthusiastic

First impressions matter, so make sure to dress professionally and arrive on time for your interview. Be polite and respectful to everyone you meet, and be enthusiastic about the opportunity to work for the company.

- Dress professionally

- Arrive on time for your interview

- Be polite and respectful

- Be enthusiastic about the opportunity

4. Ask Questions

At the end of your interview, be sure to ask questions. This shows that you’re interested in the position and that you’re taking the interview seriously. Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What are the company’s goals for the next year?

- What are the opportunities for advancement within the company?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Paint Formulator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.