Are you gearing up for a career in Paint Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Paint Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

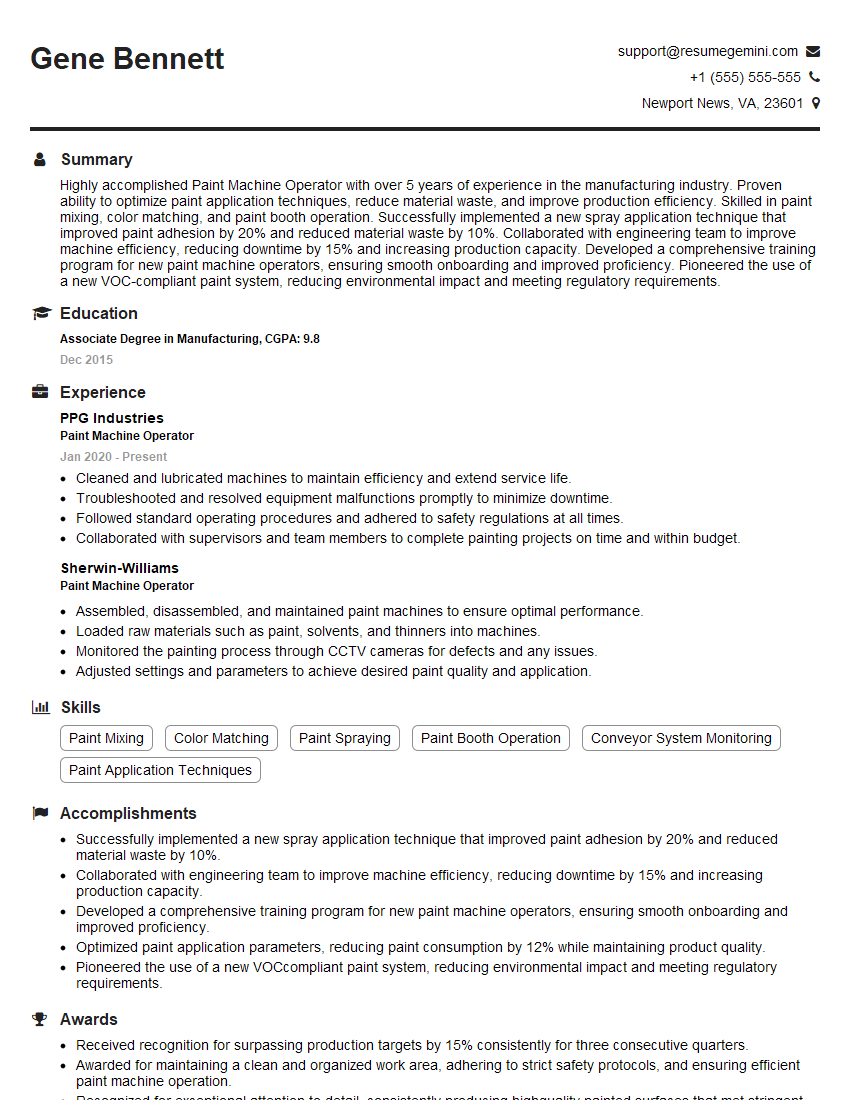

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Paint Machine Operator

1. What are the different types of paint machines and their applications?

- Airless sprayers: These are the most common type of paint machine and are used for a wide variety of applications, from small home projects to large commercial jobs. Airless sprayers use a pump to create high pressure, which forces the paint through a nozzle and atomizes it into a fine mist. This results in a smooth, even finish with minimal overspray.

- Air-assisted airless sprayers: These sprayers combine the benefits of airless sprayers with the use of compressed air to help atomize the paint. This results in a finer finish than airless sprayers, but with less overspray. Air-assisted airless sprayers are often used for painting delicate surfaces or for achieving a specific texture.

- HVLP (high volume, low pressure) sprayers: These sprayers use a turbine to create a high volume of low-pressure air, which is then used to atomize the paint. HVLP sprayers produce a finer finish than airless sprayers, but with more overspray. They are often used for painting small to medium-sized projects.

- LVLP (low volume, low pressure) sprayers: These sprayers use a turbine to create a low volume of low-pressure air, which is then used to atomize the paint. LVLP sprayers produce a very fine finish with minimal overspray. They are often used for painting delicate surfaces or for achieving a specific texture.

2. What are the safety precautions that need to be taken when operating a paint machine?

- Wear proper safety gear, including a respirator, gloves, and eye protection.

- Make sure the work area is well-ventilated.

- Follow the manufacturer’s instructions for operating the machine.

- Never point the spray gun at anyone.

- Keep the spray gun clean and free of debris.

- Be aware of the fire hazards associated with paint and solvents.

3. How do you troubleshoot a paint machine that is not working properly?

- Check the power source to make sure the machine is getting electricity.

- Check the paint supply to make sure there is enough paint in the reservoir.

- Check the nozzle to make sure it is not clogged.

- Check the filter to make sure it is not clogged.

- Check the pump to make sure it is working properly.

- Check the pressure gauge to make sure the machine is operating at the correct pressure.

- If the problem persists, consult the manufacturer’s instructions or contact a qualified technician.

4. What are the different types of paint finishes and how do you achieve them?

- Flat: Flat finishes are non-reflective and are often used on ceilings and walls. They are easy to touch up and hide imperfections.

- Matte: Matte finishes are slightly reflective and are often used on walls and trim. They are more durable than flat finishes and are easier to clean.

- Eggshell: Eggshell finishes have a slight sheen and are often used on walls and trim. They are more durable than matte finishes and are easier to clean.

- Satin: Satin finishes have a moderate sheen and are often used on walls and trim. They are more durable than eggshell finishes and are easier to clean.

- Semi-gloss: Semi-gloss finishes have a high sheen and are often used on trim, doors, and cabinets. They are very durable and easy to clean.

- Gloss: Gloss finishes have a very high sheen and are often used on trim, doors, and cabinets. They are very durable and easy to clean.

5. What are the different types of paint brushes and how do you use them?

- Natural-bristle brushes: Natural-bristle brushes are made from the hair of animals, such as pigs, horses, and goats. They are best used with oil-based paints and stains.

- Synthetic-bristle brushes: Synthetic-bristle brushes are made from man-made materials, such as nylon and polyester. They are best used with water-based paints and stains.

- Foam brushes: Foam brushes are made from a sponge-like material. They are best used for applying light coats of paint or stain.

6. What are the different types of paint rollers and how do you use them?

- Foam rollers: Foam rollers are made from a sponge-like material. They are best used for applying smooth, even coats of paint.

- Nap rollers: Nap rollers are made from a fabric material. They are best used for applying textured finishes.

7. How do you prepare a surface for painting?

- Clean the surface to remove any dirt, dust, or grease.

- Sand the surface to smooth it out and create a good surface for the paint to adhere to.

- Prime the surface to seal it and prevent the paint from absorbing into the surface.

8. How do you apply paint to a surface?

- Start by applying a thin coat of paint to the surface.

- Let the first coat dry completely before applying a second coat.

- Apply as many coats as necessary to achieve the desired finish.

9. How do you clean up after painting?

- Clean all of your brushes, rollers, and other tools with soap and water.

- Dispose of any leftover paint and solvents properly.

- Clean up any spills or drips.

10. What are some tips for painting a room?

- Start by painting the ceiling.

- Then, paint the walls.

- Finally, paint the trim.

- Use a brush to cut in around the edges of the room.

- Use a roller to apply the paint to the larger surfaces.

- Let each coat of paint dry completely before applying the next coat.

- Clean up your brushes and rollers after each use.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Paint Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Paint Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Paint Machine Operators play a crucial role in manufacturing processes by operating and maintaining automated painting machines. Their primary responsibilities include:

1. Machine Operation and Calibration

Operate paint machines to apply paint or coatings to various surfaces, ensuring uniform coverage and accuracy.

- Calibrate and adjust machine settings to achieve optimal paint application.

- Monitor machine performance and promptly identify and troubleshoot any malfunctions.

2. Paint Preparation and Application

Prepare paint mixtures according to specifications, ensuring proper viscosity and color.

- Load and unload paint into the machine, following safety protocols.

- Control and adjust paint flow to achieve desired coverage and thickness.

3. Quality Control and Inspection

Inspect painted surfaces for defects or inconsistencies, using various testing methods.

- Ensure paint adhesion, color accuracy, and surface finish meet quality standards.

- Record and document inspection results for traceability and quality assurance.

4. Maintenance and Cleaning

Perform regular maintenance on paint machines to maintain optimal performance and prevent breakdowns.

- Clean and lubricate machine components, ensuring smooth operation and longevity.

- Replace worn or damaged parts to prevent production disruptions.

Interview Tips

Preparing thoroughly for a Paint Machine Operator interview can significantly increase your chances of success. Consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products, and culture. Research the specific responsibilities and requirements of the Paint Machine Operator role.

- Visit the company website, read industry news, and connect with employees on LinkedIn.

- Identify key skills and experience highlighted in the job description.

2. Highlight Relevant Skills and Experience

Emphasize your technical proficiency in operating paint machines and your knowledge of paint preparation and application.

- Quantify your accomplishments with specific examples and metrics.

- Demonstrate your attention to detail, precision, and commitment to quality control.

3. Showcase Problem-Solving Abilities

Discuss situations where you identified and resolved machine malfunctions or quality issues effectively.

- Explain your troubleshooting process and the steps you took to minimize downtime and maintain production.

- Highlight your ability to think critically and find innovative solutions.

4. Prepare Questions for the Interviewers

Asking thoughtful questions shows your engagement and interest in the role and the company.

- Inquire about the company’s production processes and quality standards.

- Ask about opportunities for professional development and growth within the organization.

- Demonstrate your eagerness to learn and contribute to the team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Paint Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!