Are you gearing up for an interview for a Paint Roller Winder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Paint Roller Winder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

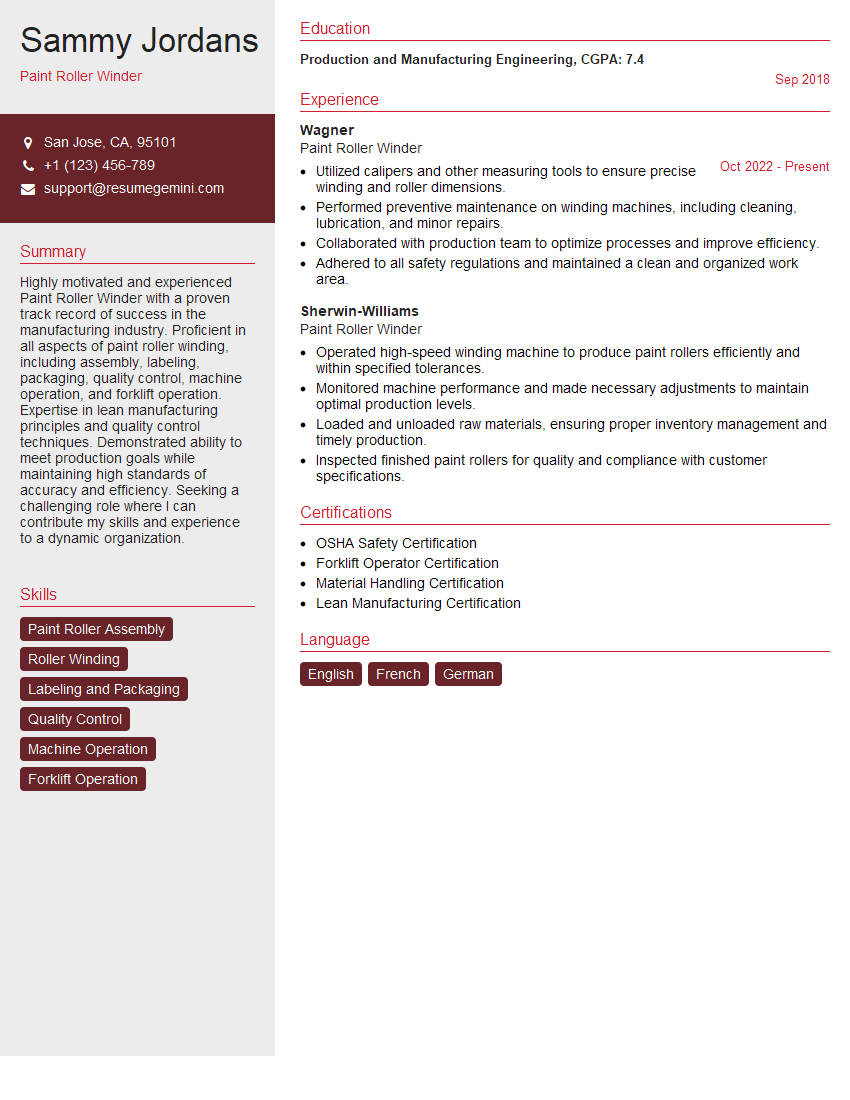

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Paint Roller Winder

1. Describe the key steps involved in winding paint rollers?

- Inspect and prepare the roller core to ensure it is clean and free of defects.

- Set up the winding machine according to the specifications of the roller to be wound.

- Load the paint roller core onto the winding mandrel and secure it.

- Feed the fabric material onto the winding mandrel and adjust the tension to prevent wrinkles or distortions.

- Start the winding process and monitor the winding speed and material tension.

- Once the desired length of fabric is wound, secure the end of the material to the roller core.

- Unload the wound roller from the winding machine and inspect it for proper winding, alignment, and any defects.

2. How do you ensure the correct tension is applied to the fabric during winding?

Calibrating the Machine

- Use a tension meter to calibrate the winding machine to the specified tension range.

- Adjust the tension control knobs or settings on the machine to achieve the desired tension.

Monitoring During Winding

- Observe the fabric as it is being wound to detect any wrinkles or distortions, which indicate improper tension.

- Adjust the tension as necessary to maintain the desired tension and prevent fabric damage or poor winding quality.

3. What are the common defects that can occur during paint roller winding and how do you prevent them?

- Wrinkles or Distortions: Caused by insufficient tension, improper fabric feeding, or uneven winding. Prevent by calibrating the machine and monitoring tension during winding.

- Skipping or Bulging: Caused by inconsistent fabric thickness or uneven winding. Prevent by ensuring uniform fabric and adjusting winding speed and tension accordingly.

- Loose or Unsecured Ends: Caused by improper securing of the fabric at the start or end of winding. Prevent by carefully tying or securing the ends to the roller core.

- Core Damage: Caused by excessive tension or improper handling. Prevent by using the correct core size and handling the rollers carefully during winding and unloading.

4. What maintenance procedures are essential for paint roller winding machines?

- Regular Cleaning: Remove dust, debris, and paint residue from the machine to prevent buildup and ensure smooth operation.

- Lubrication: Apply lubricant to moving parts, such as bearings and gears, to reduce friction and extend machine life.

- Tension Calibration: Regularly calibrate the machine’s tension settings to ensure accurate and consistent tension during winding.

- Electrical Inspection: Check electrical connections, wiring, and safety features to prevent electrical hazards.

5. Explain the importance of following safety protocols when operating paint roller winding machines.

- Wear Protective Gear: Always wear gloves, safety glasses, and appropriate clothing to protect from paint spills, dust, or machine hazards.

- Proper Machine Setup: Ensure the machine is properly installed, grounded, and leveled to prevent accidents.

- Clearance and Access: Maintain adequate clearance around the machine for safe operation and access to controls.

- Emergency Procedures: Familiarize yourself with emergency stop buttons and procedures in case of machine malfunctions or accidents.

6. Describe your experience with troubleshooting common issues that may arise during paint roller winding.

- Tension Problems: Identify if tension is too loose or too tight, adjust settings accordingly, or check for fabric thickness variations.

- Fabric Defects: Inspect fabric for wrinkles, tears, or thickness variations, and adjust winding speed or tension to mitigate issues.

- Machine Malfunctions: Diagnose and rectify electrical or mechanical issues by checking wiring, bearings, or other components.

- Poor Winding Quality: Analyze the wound roller for unevenness, loose ends, or core damage, and identify the root cause such as incorrect tension or machine settings.

7. Explain the principles of lean manufacturing and how they can be applied to paint roller winding processes

- Waste Elimination: Identify and eliminate non-value-added activities, such as excessive setup times or material handling.

- Continuous Improvement: Implement kaizen events or suggestions to optimize processes, reduce defects, and enhance efficiency.

- Pull Production: Produce rollers based on actual demand to avoid overproduction and minimize inventory.

- Visual Management: Use visual cues, such as kanban boards or standardized work instructions, to improve communication and reduce errors.

8. Discuss the role of quality control in paint roller winding operations.

- Incoming Inspection: Verify the quality of the fabric, roller cores, and other materials used in winding.

- In-Process Inspection: Monitor winding processes, check tension, and inspect rollers for defects.

- Final Inspection: Conduct thorough inspection of finished rollers for alignment, winding quality, and adherence to specifications.

- Data Analysis: Collect and analyze inspection data to identify trends, improve processes, and maintain high-quality standards.

9. Describe your knowledge of different types of paint roller materials and their suitability for various applications.

- Natural Fibers: Discuss the advantages and limitations of materials like cotton, wool, and mohair for paint rollers.

- Synthetic Fibers: Explain the properties and uses of synthetic materials such as nylon, polyester, and microfiber.

- Specialty Materials: Describe the applications and benefits of foam, rubber, or flock materials for specific paint roller needs.

10. How do you handle working with tight production deadlines while maintaining quality standards?

- Prioritization: Identify and prioritize critical tasks to ensure timely completion of urgent orders.

- Resource Allocation: Optimize resource allocation by assigning skilled operators to complex tasks and delegating simpler tasks to support staff.

- Communication: Communicate effectively with supervisors and colleagues to ensure smooth coordination and avoid bottlenecks.

- Flexibility: Adapt to changing priorities and unexpected events by adjusting production schedules or seeking support from other departments.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Paint Roller Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Paint Roller Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Paint Roller Winders manuafcture and produce paint rollers. Some of their key job responsibilities include:

1. Monitoring Production Process

Monitor production processes and equipment, including paint roller winding machines, to ensure smooth operation and identify any problems or inefficiencies.

2. Ensuring Quality Standards

Inspect paint rollers for quality, ensuring that they meet specifications and customer requirements. Identify and address any defects or non-conformances.

3. Maintaining Equipment

Perform routine maintenance and cleaning of paint roller winding machines and other equipment. Conduct minor repairs and adjustments as needed to ensure optimal performance.

4. Preparing Raw Materials

Prepare raw materials, such as fabrics and cores, for the paint roller winding process. Ensure that materials are properly cut, shaped, and sized according to specifications.

5. Packaging and Shipping

Package and ship finished paint rollers according to customer orders. Ensure that products are properly labeled, handled, and shipped to meet delivery requirements.

Interview Tips

To ace an interview for a Paint Roller Winder position, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s products, values, and industry standing. Research the specific role and its responsibilities to demonstrate your understanding and interest.

2. Highlight Relevant Skills and Experience

Emphasize your skills in manufacturing, quality control, and equipment maintenance. Showcase your knowledge of paint roller production processes and your ability to handle various raw materials.

3. Prepare Examples of Quality Control Measures

Provide concrete examples of how you have implemented and maintained quality control measures in previous roles. Explain your approach to identifying and resolving defects to ensure product quality.

4. Demonstrate Attention to Detail

Highlight your meticulous nature and attention to detail. Explain how you ensure precision in your work and maintain a clean and organized work environment.

5. Be Prepared to Discuss Safety Protocols

Discuss your understanding of safety protocols in a manufacturing setting. Explain your experience in following safety guidelines and your commitment to maintaining a safe work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Paint Roller Winder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!