Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pallet Rectifier position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

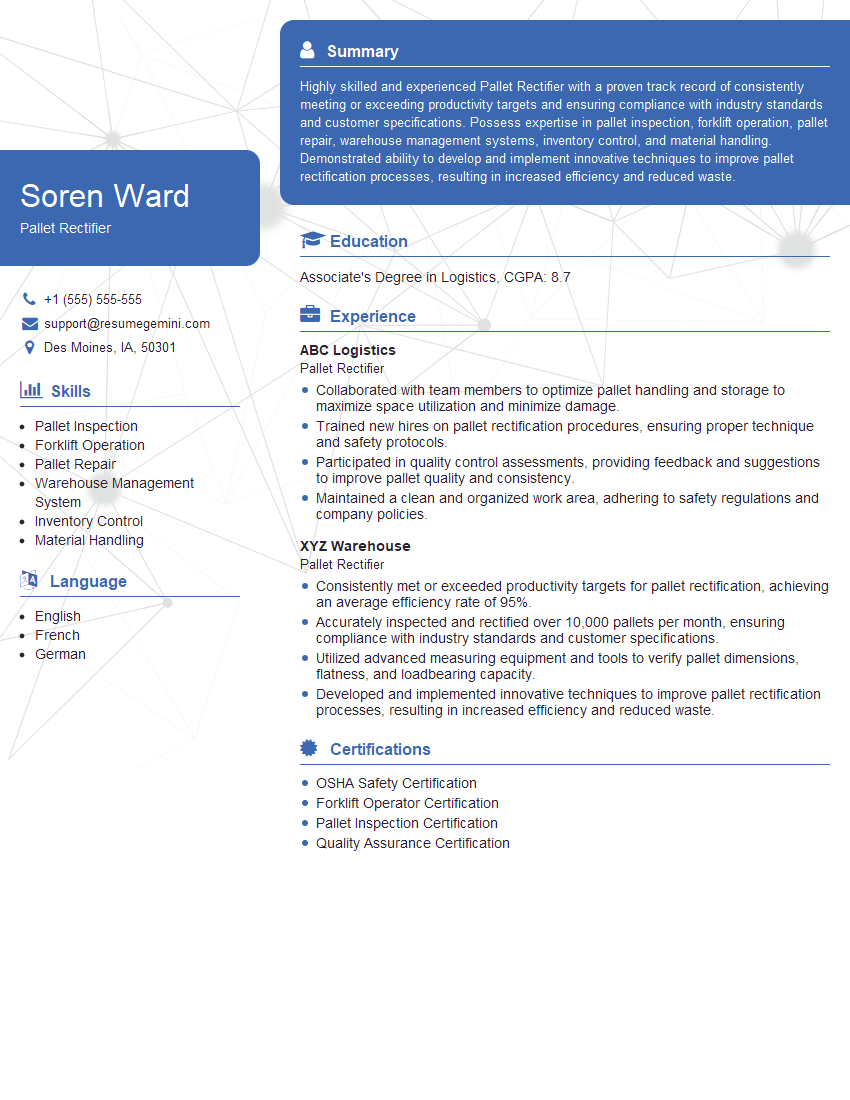

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pallet Rectifier

1. Explain the working principle of a Pallet Rectifier?

A Pallet Rectifier is a device used to convert AC (alternating current) to DC (direct current). It works on the principle of electromagnetic induction, where an alternating current flowing through a coil of wire creates a magnetic field. This magnetic field then induces an electromotive force (EMF) in a secondary coil, which is connected to the output terminals of the rectifier.

- The alternating current flows through the primary coil, creating a magnetic field.

- The magnetic field induces an EMF in the secondary coil, which is connected to the output terminals of the rectifier.

- The EMF causes current to flow in the secondary coil, which is then converted to DC by the rectifier diodes.

2. What are the different types of Pallet Rectifiers?

Full-wave Rectifiers

- Convert both positive and negative half-cycles of the AC waveform.

- Use four diodes in a bridge configuration.

- Produce a continuous DC output.

Half-wave Rectifiers

- Convert only one half-cycle of the AC waveform.

- Use one diode.

- Produce a pulsating DC output.

3. What are the factors that affect the efficiency of a Pallet Rectifier?

- Diode forward voltage drop

- Transformer losses

- Capacitor ripple current

- Filter inductor resistance

- Load resistance

4. How do you test a Pallet Rectifier?

To test a Pallet Rectifier, you can use a multimeter to measure the following:

- AC input voltage

- DC output voltage

- Diode forward voltage drop

- Transformer resistance

- Capacitor capacitance

5. What are the applications of Pallet Rectifiers?

- Power supplies

- Battery chargers

- Electroplating

- Motor drives

- Welding

6. What are the advantages of using a Pallet Rectifier?

- High efficiency

- Low ripple output

- Compact size

- Cost-effective

- Easy to install and maintain

7. What are the disadvantages of using a Pallet Rectifier?

- Diode forward voltage drop

- Transformer losses

- Capacitor ripple current

- Filter inductor resistance

- Load resistance

8. What are the safety precautions that should be taken when working with a Pallet Rectifier?

- Ensure proper grounding of the system.

- Use proper PPE (personal protective equipment).

- Do not touch the terminals of the rectifier while it is operating.

- Do not operate the rectifier in a wet or dusty environment.

- Follow the manufacturer’s instructions for installation and maintenance.

9. How do you troubleshoot a Pallet Rectifier?

To troubleshoot a Pallet Rectifier, you can perform the following steps:

- Check the AC input voltage.

- Check the DC output voltage.

- Check the diode forward voltage drop.

- Check the transformer resistance.

- Check the capacitor capacitance.

- Check the filter inductor resistance.

- Check the load resistance.

10. What are the future trends in Pallet Rectifier technology?

- Increased efficiency

- Smaller size

- Lower cost

- Improved reliability

- Increased flexibility

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pallet Rectifier.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pallet Rectifier‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Pallet Rectifier is responsible for ensuring that pallets meet the required specifications and are ready for use in the manufacturing process. The key job responsibilities include:

1. Pallet Inspection

Inspecting pallets for any defects or damage, such as broken boards, missing nails, or loose joints.

2. Pallet Repair

Repairing damaged pallets by replacing broken boards, tightening loose nails, and reinforcing weak joints.

3. Pallet Sorting

Sorting pallets by size, type, and condition to ensure that they are properly stored and used in the appropriate applications.

4. Pallet Stacking

Safely stacking pallets on racks or in designated areas to maximize storage space and minimize the risk of accidents.

5. Pallet Inventory Management

Maintaining an accurate inventory of pallets, including the number, type, and condition of pallets on hand.

Interview Tips

To help candidates ace their interview for the Pallet Rectifier position, here are some valuable tips and hacks:

1. Research the Company and Position

Demonstrate your interest and enthusiasm for the role by researching the company’s values, industry, and specific requirements for the Pallet Rectifier position.

2. Highlight Relevant Skills and Experience

Emphasize your practical skills in pallet inspection, repair, and management, as well as any experience in a warehouse or manufacturing environment.

3. Prepare for Technical Questions

Expect questions about pallet construction, repair techniques, and safety protocols. Be prepared to discuss your understanding of pallet specifications and industry standards.

4. Show Physical Fitness and Attention to Detail

This role requires physical stamina and attention to detail. Highlight your ability to perform repetitive tasks accurately and your commitment to maintaining a safe work environment.

5. Practice Common Interview Questions

Prepare for common interview questions such as “Tell me about yourself,” “Why are you interested in this role?,” and “What are your strengths and weaknesses?”

6. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally and arrive at the interview on time to demonstrate your respect for the company and the position.

7. Ask Questions at the End

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions about the company’s operations, safety procedures, or the role’s responsibilities.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pallet Rectifier, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pallet Rectifier positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.