Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pallet Sorter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

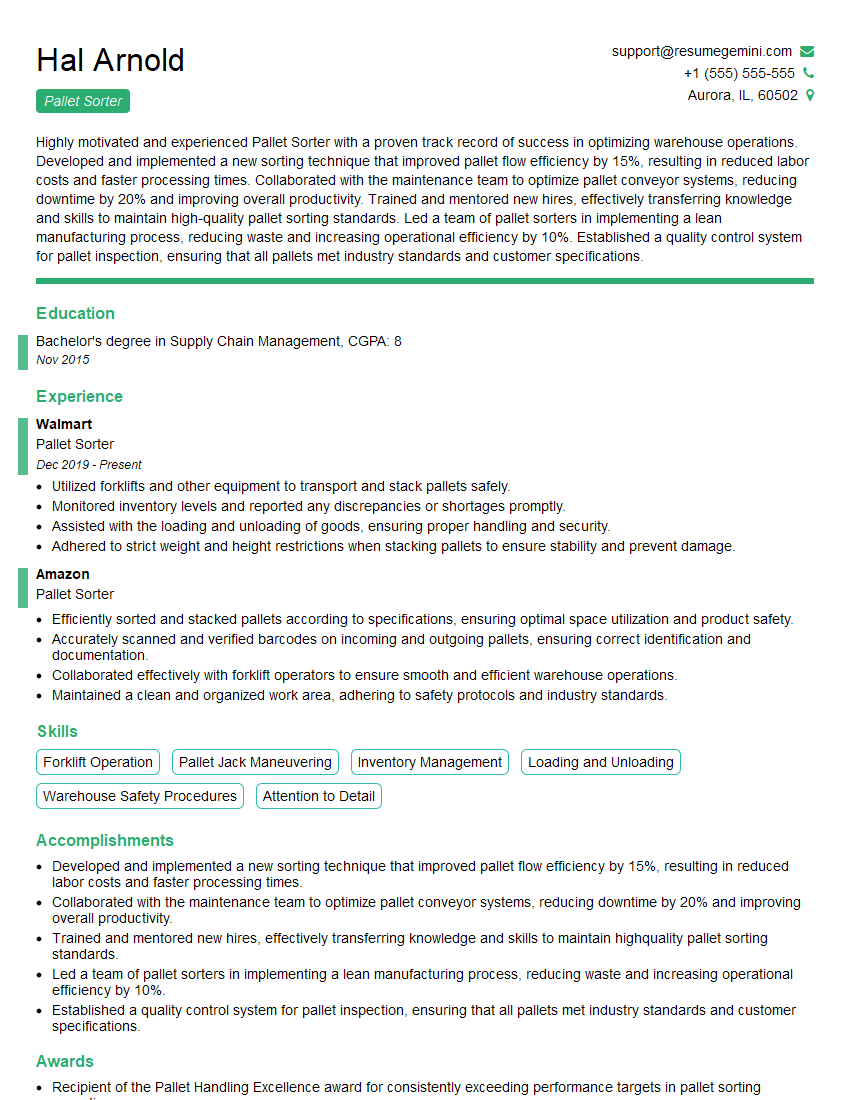

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pallet Sorter

1. Describe the different types of pallet sorters and their applications.

- Tilt-tray sorters: These sorters use trays that tilt to move pallets. They are suitable for high-speed applications and can handle a wide range of pallet sizes and weights.

- Cross-belt sorters: These sorters use belts that move in different directions to sort pallets. They are suitable for applications where space is limited and can handle a variety of pallet types.

- Chain-driven sorters: These sorters use chains to move pallets. They are suitable for heavy-duty applications and can handle large and heavy pallets.

- Push-back sorters: These sorters use a series of rails to store pallets. They are suitable for applications where space is limited and pallets need to be stored temporarily.

2. What are the key factors to consider when selecting a pallet sorter?

Throughput

- The number of pallets that the sorter needs to handle per hour.

Pallet size and weight

- The size and weight of the pallets that the sorter will be handling.

Space constraints

- The amount of space available for the sorter.

Budget

- The amount of money that is available to purchase and install the sorter.

3. How do you maintain a pallet sorter?

- Lubricate all moving parts regularly.

- Inspect the belts, chains, and rails for wear and damage.

- Clean the sorter regularly to remove debris.

- Calibrate the sorter regularly to ensure accuracy.

4. What are some common problems that can occur with pallet sorters?

- Belt slippage: This can be caused by worn or damaged belts, or by improper tension.

- Chain breakage: This can be caused by excessive wear or damage, or by improper lubrication.

- Rail misalignment: This can be caused by improper installation or by damage to the rails.

- Electrical problems: These can be caused by loose connections, damaged wires, or faulty components.

5. How do you troubleshoot a pallet sorter?

- Start by identifying the problem. This can be done by observing the sorter in operation and looking for any unusual sounds or vibrations.

- Once you have identified the problem, you can begin to troubleshoot it. This may involve checking the belts, chains, rails, and electrical components.

- Once you have found the cause of the problem, you can repair it. This may involve replacing a worn belt, tightening a chain, or repairing a damaged rail.

6. What are the safety precautions that need to be taken when working with pallet sorters?

- Always wear proper safety gear, including safety glasses, gloves, and a hard hat.

- Never enter the sorter area while it is in operation.

- Be aware of the pinch points and moving parts.

- Follow all safety instructions provided by the manufacturer.

7. What are the benefits of using a pallet sorter?

- Increased efficiency: Pallet sorters can help to increase the efficiency of your warehouse operations by automating the sorting process.

- Reduced labor costs: Pallet sorters can help to reduce labor costs by eliminating the need for manual sorting.

- Improved accuracy: Pallet sorters are more accurate than manual sorting, which can reduce the number of errors.

- Increased productivity: Pallet sorters can help to increase productivity by reducing the time it takes to sort pallets.

8. What are the different types of control systems used for pallet sorters?

- Mechanical control systems: These systems use mechanical components, such as levers and gears, to control the sorter.

- Electrical control systems: These systems use electrical components, such as sensors and motors, to control the sorter.

- Computer control systems: These systems use computers to control the sorter.

9. What are the advantages and disadvantages of each type of control system?

Mechanical control systems

- Advantages:

- Simple and reliable

- Low cost

- Disadvantages:

- Limited flexibility

- Not suitable for complex applications

Electrical control systems

- Advantages:

- More flexible than mechanical control systems

- Suitable for more complex applications

- Disadvantages:

- More expensive than mechanical control systems

- More complex to maintain

Computer control systems

- Advantages:

- Most flexible of all control systems

- Suitable for the most complex applications

- Disadvantages:

- Most expensive of all control systems

- Most complex to maintain

10. How do you select the right control system for a pallet sorter?

- Consider the following factors:

- The type of sorter

- The application

- The budget

- The maintenance requirements

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pallet Sorter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pallet Sorter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pallet sorters play a pivotal role in the warehouse operations ecosystem, ensuring the efficient and accurate distribution of goods. Their primary responsibilities encompass:

1. Pallet Sorting and Dispensing

The core function of a pallet sorter is to sort and dispense pallets based on predetermined criteria such as size, weight, destination, or order requirements. This involves identifying pallets using barcodes or RFID tags, directing them to the correct sorting lanes, and ensuring their safe and timely delivery to designated areas.

2. System Monitoring and Maintenance

Pallet sorters must constantly monitor the sorting system’s performance, ensuring smooth operations and identifying any potential issues. Regular maintenance tasks are also crucial to prevent breakdowns and maintain optimal efficiency.

3. Inventory Management

Pallet sorters contribute to inventory management by providing real-time visibility into pallet movements. They maintain records of pallets sorted and dispensed, enabling efficient stock tracking and inventory replenishment.

4. Safety and Compliance

Pallet sorters must prioritize safety in all aspects of their work. Proper handling of pallets, adherence to safety protocols, and maintaining a clean and organized work area are paramount. They must also comply with all applicable regulations and standards.

Interview Tips

Acing an interview for a pallet sorter position requires thorough preparation and showcasing relevant skills and experience. Here are some tips to help candidates excel:

1. Research the Company and Role

Gather information about the company’s industry, size, and culture. Familiarize yourself with the specific requirements of the pallet sorter role, including the required skills, experience, and responsibilities.

- Visit the company’s website and social media pages

- Read industry publications and articles

- Network with professionals in the field

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating and maintaining pallet sorting systems. Quantify your accomplishments and provide specific examples of your contributions to previous projects. Showcase your ability to work efficiently in a fast-paced environment and handle multiple tasks simultaneously.

- Use the STAR method (Situation, Task, Action, Result) to describe your experiences

- Prepare examples of how you have improved safety and efficiency in previous roles

- Discuss your knowledge of inventory management systems and data collection techniques

3. Demonstrate Safety and Compliance Awareness

Highlight your commitment to safety and compliance. Describe your understanding of industry regulations and best practices. Explain how you ensure a safe and efficient work environment.

- Share examples of your safety initiatives and accomplishments

- Explain your knowledge of OSHA and ANSI standards

- Discuss your experience with conducting safety audits and training

4. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivation. Practice your answers to ensure they are clear, concise, and tailored to the role.

- “Tell me about your experience operating and maintaining pallet sorting systems.”

- “How do you prioritize safety in your work environment?”

- “Describe a time when you faced a challenge in sorting and dispensing pallets.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pallet Sorter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!