Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Palletizer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

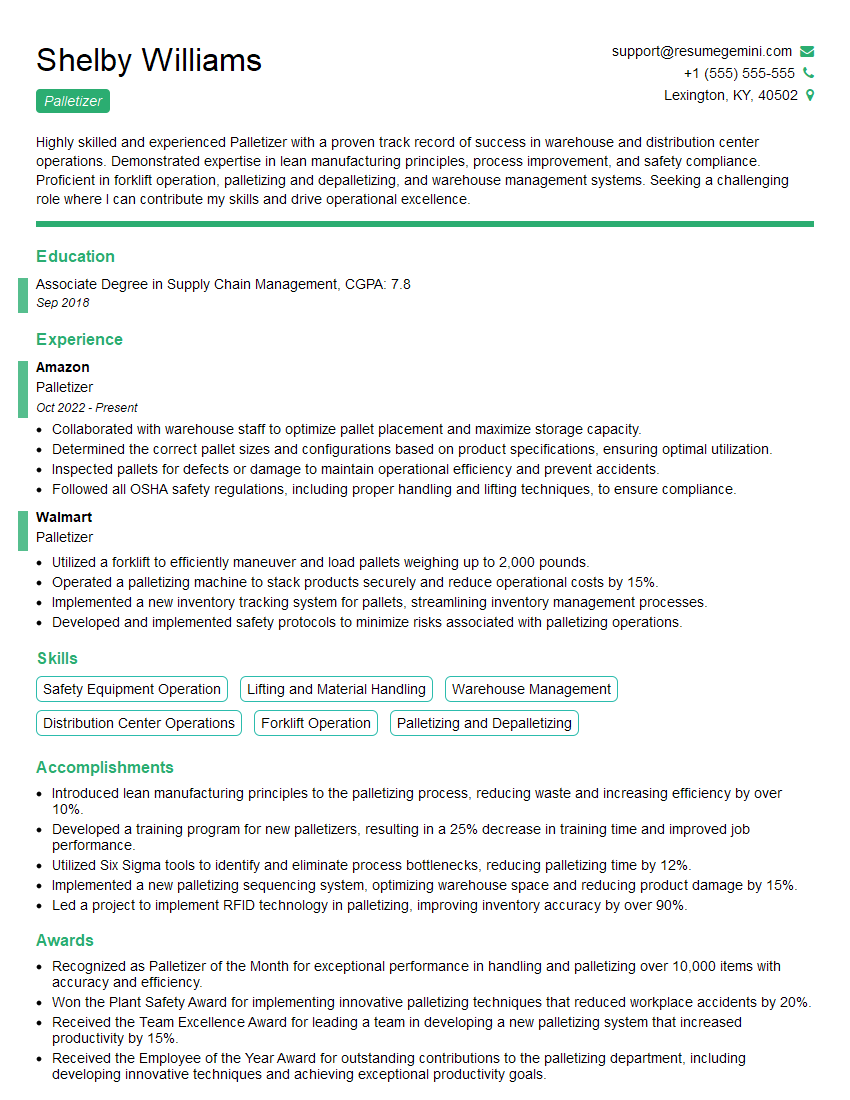

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Palletizer

1. What are the different types of palletizers?

There are three main types of palletizers:

- Conventional palletizers: These are the most common type of palletizer and are used for a wide variety of applications. They use a robotic arm to place products on a pallet.

- High-speed palletizers: These palletizers are designed to handle high volumes of products and can operate at speeds of up to 100 cases per minute.

- Robotic palletizers: These palletizers use a robot to place products on a pallet. They are more flexible than conventional palletizers and can be used for a wider variety of applications.

2. What are the key factors to consider when selecting a palletizer?

Factors:

- The type of product being palletized

- The size and weight of the product

- The desired output rate

- The available space

- The budget

3. What are the benefits of using a palletizer?

- Increased productivity: Palletizers can run significantly faster than manual labor, allowing you to palletize more products in less time.

- Reduced labor costs: Palletizers eliminate the need for manual labor, which can save you money on labor costs.

- Improved safety: Palletizers reduce the risk of injuries to workers, as they eliminate the need for manual lifting.

- Increased accuracy: Palletizers can be programmed to place products on pallets with precision, which can help to reduce product damage.

4. What are the different types of products that can be palletized?

A wide variety of products can be palletized, including:

- Boxes

- Bags

- Drums

- Bottles

- Cans

- Pallets

5. What are the different types of pallets that can be used with a palletizer?

There are several different types of pallets that can be used with a palletizer, including:

- Wood pallets

- Plastic pallets

- Metal pallets

- Corrugated pallets

6. What are the safety precautions that should be taken when operating a palletizer?

- Make sure that the palletizer is properly installed and maintained.

- Wear appropriate personal protective equipment (PPE), such as safety glasses and gloves.

- Never operate a palletizer while under the influence of drugs or alcohol.

- Be aware of your surroundings and avoid contact with moving parts.

- Follow all safety instructions provided by the manufacturer.

7. What are the different maintenance tasks that should be performed on a palletizer?

Maintenance tasks:

- Lubricate moving parts

- Inspect electrical components

- Check for loose bolts and screws

- Clean the palletizer

- Calibrate the palletizer

8. What troubleshooting steps should be taken if a palletizer is not working properly?

Troubleshooting:

- Check the power supply

- Check the fuses

- Check the sensors

- Check the actuators

- Check the software

9. What are the latest trends in palletizing technology?

The latest trends in palletizing technology include:

- The use of robots

- The use of artificial intelligence (AI)

- The use of cloud-connected palletizers

- The use of sustainable materials

10. What are the challenges facing the palletizing industry?

The palletizing industry is facing a number of challenges, including:

- The rising cost of labor

- The need for increased productivity

- The need for greater flexibility

- The need for more sustainable solutions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Palletizer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Palletizer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Palletizer, you will be responsible for ensuring that products are safely and efficiently palletized and loaded onto trucks or other transport vehicles.

1. Load and Unload Products

You will be required to load and unload products from conveyor belts or other equipment and stack them onto pallets.

- Read and understand work orders to ensure that products are loaded and unloaded according to specifications.

- Use forklifts, pallet jacks, and other equipment to move and stack pallets.

2. Keep Workplace Clean and Organized

You will be responsible for maintaining the cleanliness and organization of your work area.

- Sweep and clean floors, wipe down equipment, and remove debris.

- Inspect pallets and equipment for damage and report any issues to supervisors.

3. Work Safely

You must always follow safety procedures and wear appropriate personal protective equipment.

- Be aware of your surroundings and identify potential hazards.

- Use equipment safely and follow lockout/tagout procedures.

4. Maintain Equipment

You will be required to perform basic maintenance on equipment, such as cleaning and lubricating.

- Report any equipment problems to supervisors.

- Keep a log of maintenance activities.

Interview Tips

Preparing for an interview for a Palletizer position requires research, practice, and confidence. Here are some tips to help you ace the interview:

1. Research the Company

Before the interview, take the time to research the company and the specific role you are applying for.

- Visit the company’s website and read about their mission, values, and products.

- Look up the company on social media to get a sense of their culture and recent news.

2. Practice Your Answers

Take some time to think about the most common interview questions and prepare your answers.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Practice answering questions out loud to a friend or family member.

3. Dress Professionally

First impressions matter, so dress professionally for your interview.

- Wear clean, pressed clothes.

- Choose clothes that are appropriate for the company culture and the role you are applying for.

4. Be Confident

Confidence is key in an interview.

- Make eye contact with the interviewer and speak clearly.

- Be enthusiastic and positive about your skills and experience.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Palletizer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.