Are you gearing up for an interview for a Panel Edge Sealer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Panel Edge Sealer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

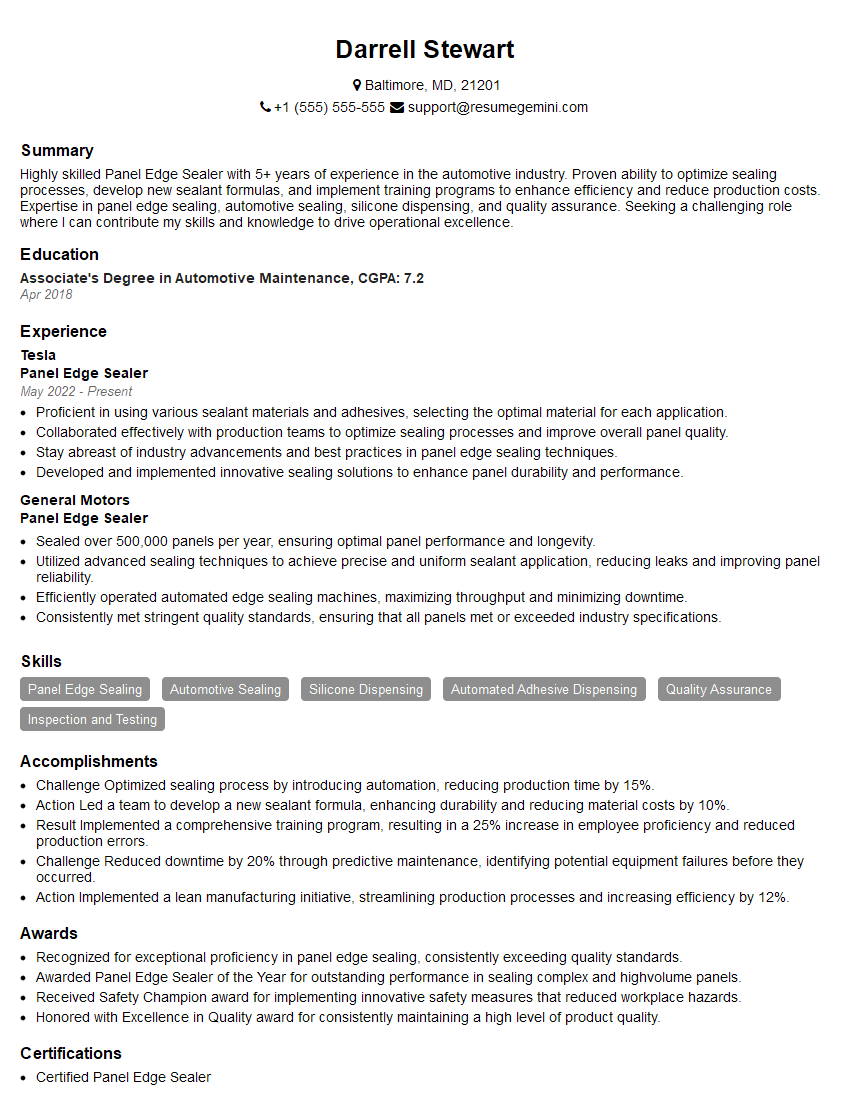

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Panel Edge Sealer

1. Describe the critical steps of the panel edge sealing process?

The critical steps of the panel edge sealing process include:

- Preparing the panel surface

- Applying the sealant

- Smoothing the sealant

- Inspecting the seal

2. What are the different types of panel edge sealants, and when would you use each type?

The different types of panel edge sealants include:

Butyl Rubber Sealant

- Adhesive and elastic properties

- Used to seal joints between metal panels

Silicone Sealant

- Water-resistant and flexible

- Used to seal joints between different types of materials

Polyurethane Sealant

- Strong and durable

- Used to seal joints in high-traffic areas

Acrylic Sealant

- Paintable and easy to apply

- Used to seal joints in areas where aesthetics are important

3. What are the most common problems that can occur during the panel edge sealing process, and how do you resolve them?

The most common problems that can occur during the panel edge sealing process include:

- Bubbles in the sealant: This can be caused by improper mixing of the sealant or by applying the sealant to a wet surface. To resolve this problem, remove the bubbles with a pin or needle and smooth the sealant.

- Cracks in the sealant: This can be caused by applying the sealant too thinly or by exposing it to excessive heat or cold. To resolve this problem, remove the cracked sealant and apply a new layer.

- Discoloration of the sealant: This can be caused by exposure to UV light or by the sealant reacting with the surface it is applied to. To resolve this problem, clean the sealant with a mild detergent and apply a new layer.

4. What are the safety precautions that must be taken when working with panel edge sealants?

The safety precautions that must be taken when working with panel edge sealants include:

- Wear gloves and eye protection

- Work in a well-ventilated area

- Avoid contact with skin and eyes

- Do not ingest the sealant

- Dispose of the sealant properly

5. What are the latest trends in panel edge sealing technology?

The latest trends in panel edge sealing technology include:

- The use of robotic sealants: This allows for more precise and efficient application of the sealant.

- The development of new sealant materials: These materials are more durable and resistant to weathering.

- The use of sustainable sealants: These sealants are made from renewable resources and have a lower environmental impact.

6. What is your favorite panel edge sealant, and why?

My favorite panel edge sealant is silicone sealant because it is water-resistant, flexible, and easy to apply. It is also very durable and can withstand exposure to UV light and extreme temperatures.

7. How do you stay up-to-date on the latest trends in panel edge sealing technology?

I stay up-to-date on the latest trends in panel edge sealing technology by reading industry publications, attending trade shows, and participating in online forums.

8. What are your career goals?

My career goals are to become a project manager in the construction industry. I am confident that my skills and experience in panel edge sealing will be valuable to me in this role.

9. Why are you interested in working for our company?

I am interested in working for your company because I am impressed by your commitment to quality and customer service. I believe that my skills and experience would be a valuable asset to your team.

10. What are your salary expectations?

My salary expectations are commensurate with my experience and qualifications. I am confident that I can negotiate a fair salary that is in line with industry standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Panel Edge Sealer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Panel Edge Sealer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Panel Edge Sealer is accountable for implementing and adhering to the established processes of manufacturing operations pertaining to the sealing of panel edges. They ensure quality control and efficiency within their area of expertise.

1. Panel Preparation and Sealing

Prepare panels for the sealing process by cleaning and applying primer as per the specified procedures.

- Operate and maintain panel edge sealing equipment, including automatic and manual sealers.

- Ensure accurate application of sealant to panel edges, adhering to defined parameters for thickness and coverage.

2. Quality Control and Inspection

Inspect sealed panels to verify the quality of sealant application, ensuring compliance with established standards.

- Identify any defects or deviations from specifications and take corrective actions promptly.

- Maintain records of inspections conducted and document any non-conformances encountered.

3. Production Efficiency

Monitor the sealing process to optimize production efficiency and minimize downtime.

- Identify and address bottlenecks in the production line to improve throughput.

- Train and supervise production team members to ensure proper sealing techniques and adherence to quality standards.

4. Collaboration and Communication

Collaborate effectively with colleagues in other departments, such as engineering and production, to ensure seamless coordination.

- Provide input on process improvements and suggest modifications to enhance overall production efficiency.

- Communicate any issues or concerns related to the sealing process to relevant parties for timely resolution.

Interview Tips

Here are some interview tips and preparation hacks to help you ace your interview for a Panel Edge Sealer position:

1. Research the Company and Position

Before the interview, take the time to research the company you are applying to and the specific role you are interviewing for. This demonstrates your interest and enthusiasm for the position and shows that you have taken the time to prepare.

- Visit the company’s website to learn about their products, services, and culture.

- Read industry-related news and articles to stay up-to-date on the latest trends and developments.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers in advance. This will help you feel more confident and articulate during the interview.

- Start by identifying your strengths and weaknesses and how they relate to the job requirements.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your experience.

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the Panel Edge Sealer role. Emphasize your ability to:

- Operate and maintain panel edge sealing equipment.

- Inspect sealed panels for quality and ensure compliance with specifications.

- Identify and address bottlenecks in the production process to improve efficiency.

4. Ask Insightful Questions

At the end of the interview, take the opportunity to ask the interviewer questions about the company, the role, and the team you would be working with. This shows that you are engaged and interested in the position.

- Ask about the company’s growth plans and future goals.

- Inquire about the specific challenges and opportunities associated with the role.

- Ask about the company’s commitment to training and development.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Panel Edge Sealer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Panel Edge Sealer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.