Are you gearing up for an interview for a Panel Lay-Up Worker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Panel Lay-Up Worker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

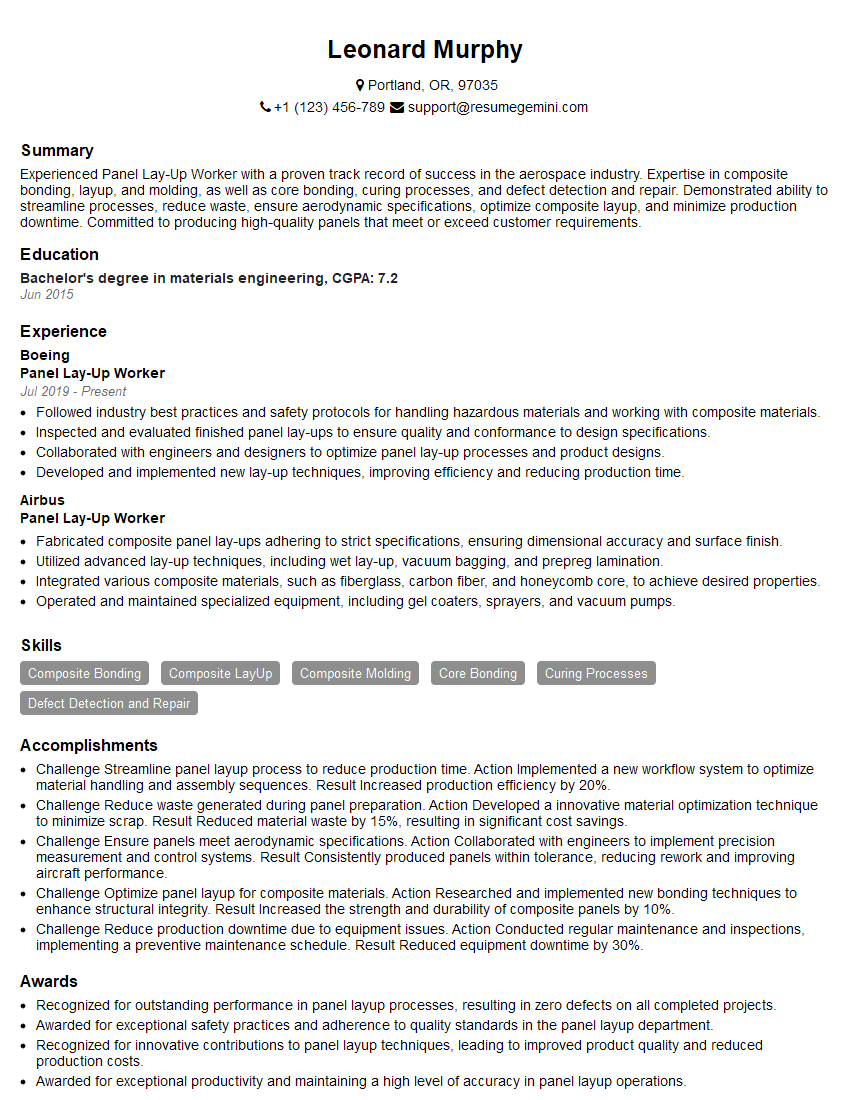

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Panel Lay-Up Worker

1. What are the different types of composite materials used in panel lay-up?

Composite materials used in panel lay-up include:

- Carbon fiber reinforced polymer (CFRP)

- Glass fiber reinforced polymer (GFRP)

- Aramid fiber reinforced polymer (AFRP)

- Polyethylene terephthalate (PET)

- Polypropylene (PP)

2. Describe the process of bonding composite panels to a core material.

Surface Preparation:

- Clean and prepare the surfaces of the composite panels and the core material.

- Apply a bonding agent to the surfaces.

Lay-up:

- Position the composite panels on the core material.

- Apply pressure and heat to bond the panels to the core.

Curing:

- Allow the bonded assembly to cure according to the manufacturer’s recommendations.

- Inspect the bond for strength and integrity.

3. How do you ensure the accuracy of panel lay-up operations?

- Use precision measuring tools.

- Follow detailed work instructions.

- Regularly calibrate equipment.

- Inspect panels at each stage of the process.

- Document all critical dimensions.

4. What are the safety precautions that must be taken when working with composite materials?

- Wear appropriate personal protective equipment (PPE) such as gloves, respirators, and safety glasses.

- Handle composite materials with care to avoid cuts and abrasions.

- Be aware of the potential for dust and fumes generated during cutting and sanding.

- Follow proper disposal procedures for hazardous materials.

- Maintain a clean and organized work area.

5. How do you maintain and calibrate the equipment used in panel lay-up operations?

- Follow the manufacturer’s instructions for maintenance and calibration.

- Regularly inspect equipment for wear and tear.

- Calibrate equipment using certified standards.

- Maintain a record of maintenance and calibration activities.

- Train operators on proper equipment usage.

6. What are the different types of defects that can occur during panel lay-up?

- Delamination

- Voids

- Cracks

- Warping

- Foreign object damage

7. How do you inspect panels for defects?

- Visual inspection

- Ultrasonic testing

- X-ray inspection

- Tap testing

- Acoustic emission testing

8. What is the importance of quality control in panel lay-up operations?

- Ensures panels meet specifications and requirements.

- Reduces the risk of defects and failures.

- Improves the safety and reliability of the final product.

- Enhances customer satisfaction.

- Minimizes costs associated with rework and scrap.

9. What are the latest trends and advancements in panel lay-up technology?

- Automated lay-up systems

- Use of new materials such as carbon nanotubes and graphene

- Non-destructive testing methods

- Digitalization and data analytics

- Sustainability and environmental considerations

10. How do you stay up-to-date with the latest developments in panel lay-up technology?

- Attend industry conferences and exhibitions.

- Read technical journals and articles.

- Participate in training programs.

- Network with industry professionals.

- Follow social media and online forums.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Panel Lay-Up Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Panel Lay-Up Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Panel Lay-Up Worker, you will play a pivotal role in the fabrication and assembly of composite panels, contributing to the overall success of the manufacturing process.

1. Panel Fabrication and Assembly

You will be primarily responsible for fabricating composite panels according to specified designs and blueprints.

- Lay up and laminate composite materials, including fiberglass, carbon fiber, and other reinforcements.

- Operate specialized equipment such as vacuum bagging systems, autoclaves, and curing ovens to cure and bond materials.

2. Quality Assurance and Inspection

Ensuring the quality of the panels is crucial, and you will be involved in various inspection and testing procedures.

- Perform visual inspections, dimensional measurements, and non-destructive testing to verify adherence to specifications.

- Identify and document any defects or deviations from the design to facilitate timely corrective actions.

3. Process Optimization and Continuous Improvement

Continuous improvement is key in the manufacturing industry, and you will be encouraged to contribute to the optimization of processes.

- Analyze production data and identify areas for improvement, such as reducing cycle times or minimizing waste.

- Collaborate with engineers and supervisors to implement process enhancements that increase efficiency and quality.

4. Safety and Compliance

Maintaining a safe and compliant work environment is paramount, and you will be responsible for adhering to safety regulations.

- Follow established safety protocols, wear appropriate personal protective equipment (PPE), and report any potential hazards.

- Ensure that all equipment is properly calibrated, maintained, and operated in accordance with safety guidelines.

Interview Tips

Preparing thoroughly for your interview will significantly increase your chances of success. Here are some tips to help you ace the interview and land your dream job as a Panel Lay-Up Worker:

1. Research the Company and the Position

Before the interview, take the time to research the company and the specific position you are applying for. This will give you a good understanding of the company’s culture, products or services, and the responsibilities of the role.

- Visit the company’s website to learn about its mission, values, and recent news.

- Read the job description carefully and identify the key skills and qualifications that the employer is seeking.

2. Practice Your Answers to Common Interview Questions

There are certain questions that are commonly asked in interviews for Panel Lay-Up Worker positions. By preparing your answers to these questions in advance, you will be able to respond confidently and effectively.

- Tell me about your experience in fabricating and assembling composite panels.

- Give me an example of a time when you identified and resolved a quality issue.

- How do you stay up-to-date on the latest advancements in composite manufacturing?

3. Highlight Your Skills and Experience

During the interview, it is important to highlight your skills and experience that are relevant to the position. Be prepared to discuss your:

- Technical skills in composite fabrication and assembly, including lay-up techniques, curing methods, and quality control procedures.

- Experience working in a manufacturing environment and adhering to safety protocols.

- Ability to work independently and as part of a team to achieve production goals.

4. Be Enthusiastic and Professional

First impressions matter, so it is important to be enthusiastic and professional throughout the interview. Dress appropriately, arrive on time, and make a positive impression by being polite and respectful to the interviewer.

- Maintain eye contact, speak clearly, and engage in active listening.

- Ask thoughtful questions about the company and the position to show your interest and enthusiasm.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Panel Lay-Up Worker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.