Are you gearing up for an interview for a Pantograph Machine Set-Up Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pantograph Machine Set-Up Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

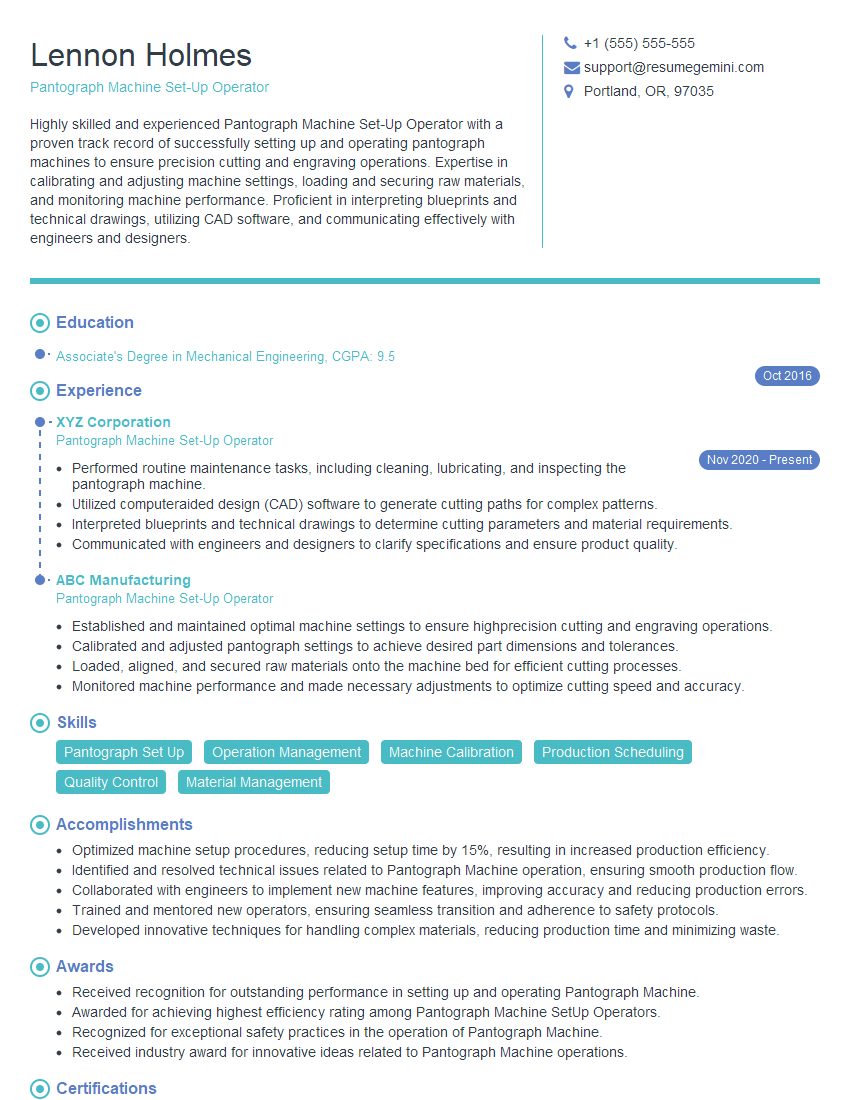

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pantograph Machine Set-Up Operator

1. How do you set up a pantograph machine?

During setup, I ensure that the machine is properly calibrated and adjusted to meet the specific requirements of the job. This involves:

- Mounting the pantograph stylus and adjusting its position and pressure to achieve optimal tracing accuracy.

- Positioning the work piece securely on the machine’s table and aligning it with the pantograph’s path.

- Setting the cutting depth, speed, and feed rate based on the material being processed and the desired result.

2. Explain the different types of pantographs and their applications.

Mechanical Pantographs

- Manual: Operated by hand, used for engraving, tracing, and pattern making.

- Motorized: Automated versions, used for high-volume production in industries like woodworking and metalworking.

Computer-Controlled Pantographs

- CNC Pantographs: Controlled by computer programs, allowing for complex designs and precise cutting.

- Laser Pantographs: Use laser beams for cutting and engraving, offering high precision and speed.

3. How do you maintain a pantograph machine?

Regular maintenance is crucial for optimal performance and longevity of the machine. I perform the following tasks:

- Lubricating moving parts to minimize friction and wear.

- Cleaning the machine to remove dust, debris, and chips that could affect accuracy.

- Inspecting the cutting stylus and replacing it when necessary to ensure sharpness and precision.

- Calibrating the machine regularly to maintain accuracy and prevent errors.

4. What are the safety precautions to consider when operating a pantograph machine?

Safety is paramount when operating a pantograph machine. I adhere to the following measures:

- Wearing appropriate safety gear, including gloves, safety glasses, and protective clothing.

- Ensuring the machine is properly grounded to prevent electrical hazards.

- Maintaining a clean and organized work area to minimize tripping hazards.

- Never operating the machine while under the influence of drugs or alcohol.

5. How do you troubleshoot common problems with pantograph machines?

I have experience in identifying and resolving various issues that may arise with pantograph machines. Some common problems include:

- Inaccurate cuts: This could be due to misalignment, dull cutting stylus, or incorrect settings.

- Machine vibrations: Loose or worn components, such as bearings or belts, can cause vibrations that affect accuracy.

- Motor overheating: Overloading the machine or insufficient lubrication can lead to motor overheating.

6. What is the role of a pantograph machine in mass production?

Pantograph machines play a significant role in mass production scenarios by:

- Automating the cutting process, improving efficiency and productivity.

- Ensuring consistent and precise cuts, reducing scrap and rework.

- Allowing for complex designs to be replicated quickly and accurately.

7. How do you optimize cutting parameters for different materials?

Optimizing cutting parameters is crucial for efficient and high-quality results. I consider the following factors:

- Material properties: Hardness, thickness, and grain structure.

- Cutting tool: Type, sharpness, and geometry.

- Desired finish and precision requirements.

8. What quality control measures do you implement to ensure accuracy and precision?

Accuracy and precision are vital in pantograph operations. I implement the following quality control measures:

- Regular calibration and inspection of the machine.

- Using precision measuring tools to verify the dimensions and tolerances of the finished product.

- Monitoring the cutting process and making adjustments as necessary.

9. How do you handle tight deadlines and production targets?

Meeting deadlines and production targets is essential in any manufacturing environment. I employ the following strategies:

- Prioritizing tasks and allocating resources effectively.

- Optimizing machine settings and cutting parameters.

- Working overtime or in shifts, if necessary.

10. What are your career goals and aspirations in this field?

I am passionate about pantograph operations and aim to excel in this field. My career goals include:

- Developing expertise in complex pantograph applications.

- Supervising and training junior operators.

- Exploring new technologies and advancements in pantograph machines.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pantograph Machine Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pantograph Machine Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Pantograph Machine Set-Up Operator plays a pivotal role in ensuring the efficient functioning of pantograph machines, which are essential for creating intricate designs and patterns on various materials. The key job responsibilities include:

1. Machine Setup and Operation

Setting up and operating pantograph machines to cut, etch, or engrave designs on materials such as metal, plastic, or wood.

- Loading and unloading materials into the machine

- Adjusting machine settings and parameters based on the design specifications

- Guiding the cutting or engraving tool through the material to create the desired design

2. Design Creation and Modification

Translating design concepts into machine-readable instructions.

- Using computer-aided design (CAD) software to create or modify designs

- Optimizing designs for efficient and accurate machine execution

- Making necessary adjustments to designs to ensure they meet the desired specifications

3. Quality Control and Inspection

Ensuring that the finished products meet the required quality standards.

- Inspecting the finished products for errors or defects

- Identifying and correcting any deviations from the design specifications

- Maintaining records of inspection and quality control procedures

4. Machine Maintenance and Troubleshooting

Maintaining the pantograph machine in optimal working condition.

- Performing routine maintenance and cleaning procedures

- Identifying and resolving minor malfunctions or issues

- Escalating major repairs or maintenance needs to the appropriate personnel

Interview Tips

Preparing for an interview for a Pantograph Machine Set-Up Operator position requires thorough preparation and understanding of the role’s responsibilities. Here are some tips and hacks to help you ace the interview:

1. Research the Company and Role

Take the time to research the company and the specific role you’re applying for. This will give you a good understanding of the company’s culture, values, and the expectations for the position.

- Visit the company’s website to learn about their history, mission, and products or services.

- Read industry-specific publications and articles to stay up-to-date on the latest trends and technologies.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful answers that highlight your skills, experience, and qualifications. Practice delivering your answers out loud to improve your confidence and articulation.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Focus on quantifying your accomplishments and providing data-driven results whenever possible.

3. Showcase Your Technical Skills

In addition to general interview questions, you may be asked technical questions about pantograph machines or related technologies. Be prepared to discuss your expertise in the following areas:

- Pantograph machine operation and setup

- CAD software and design principles

- Quality control and inspection techniques

- Machine maintenance and troubleshooting

4. Highlight Your Attention to Detail

As a Pantograph Machine Set-Up Operator, attention to detail is crucial. Emphasize your ability to pay meticulous attention to instructions, follow design specifications precisely, and ensure the accuracy and quality of finished products.

- Provide examples of projects where you demonstrated your ability to meet tight tolerances and produce high-quality results.

- Describe your quality control processes and how you ensure that products meet customer requirements.

Next Step:

Now that you’re armed with the knowledge of Pantograph Machine Set-Up Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pantograph Machine Set-Up Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini