Are you gearing up for an interview for a Paper Cap Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Paper Cap Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

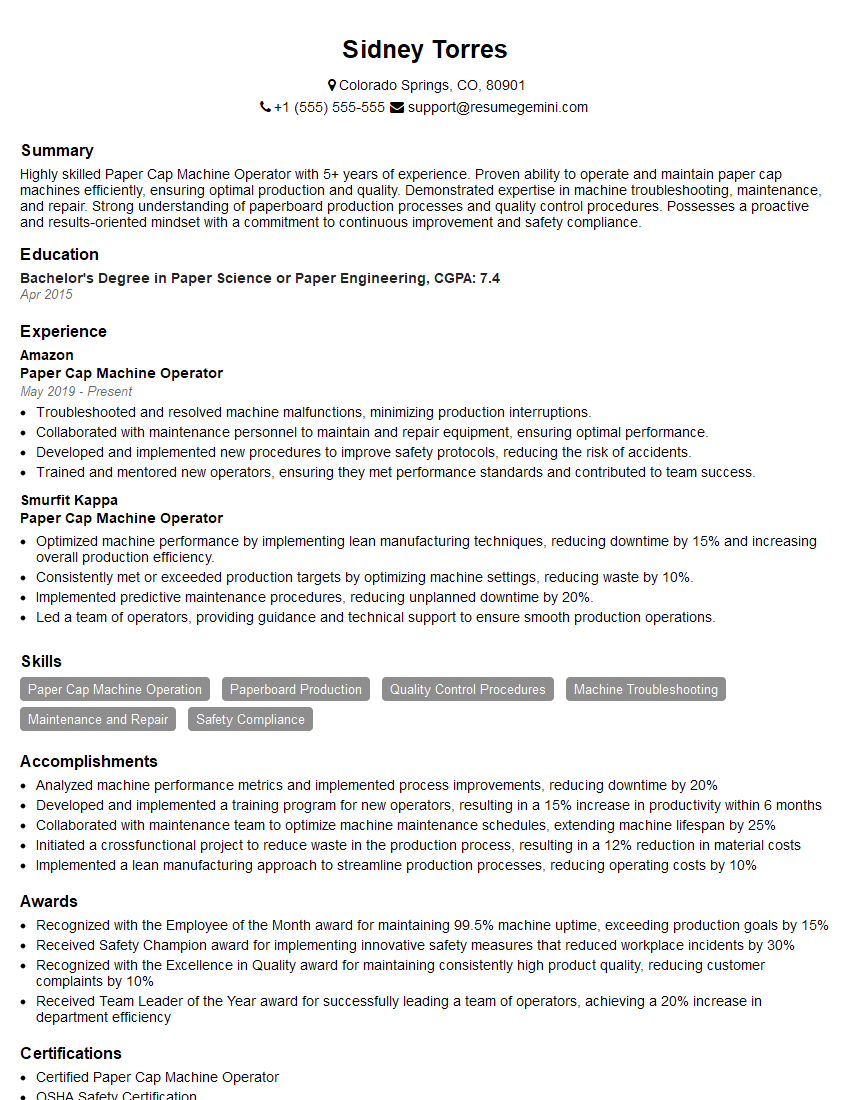

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Paper Cap Machine Operator

1. What are your experiences and knowledge in making Cap details on paper cap machine?

In my previous role as a Paper Cap Machine Operator, I was responsible for all aspects of making Cap details on the machine. I have a deep understanding of the machine’s operation and maintenance, and I am proficient in making a variety of Cap details. Some of my key responsibilities included:

- Setting up and operating the machine

- Monitoring the machine and making adjustments as needed

- Troubleshooting and repairing minor machine malfunctions

- Making a variety of Cap details to customer specifications

- Ensuring that all Cap details met quality standards

2. Can you describe the qualities and properties of paper used in the production of caps?

Factors affecting quality of paper

- Paper quality is essential for producing high-quality caps.

- Some of the key factors that affect the quality of paper for cap production include:

Factors affecting properties of paper

- GSM (grams per square meter)

- Caliper (thickness)

- Opacity

- Brightness

- Stiffness

- Moisture content

3. What is the role of glue in the production of paper caps?

Glue plays a vital role in the production of paper caps. It is used to bind the different components of the cap together, including the paper, the brim, and the sweatband. The type of glue used will depend on the specific materials being used, but it is important to use a glue that is strong and durable enough to withstand the wear and tear of everyday use.

4. Can you explain the process of creasing and folding paper caps?

Creasing and folding are essential steps in the production of paper caps. Creasing involves making a sharp fold in the paper, while folding involves bending the paper along a crease. These techniques are used to shape the cap and give it its characteristic form.

- Creasing is typically done using a creasing machine, which applies pressure to the paper to create a sharp fold.

- Folding is typically done by hand, using a bone folder or other tool to smooth out the fold.

5. What are the different types of paper cap machines and their applications?

There are two main types of paper cap machines: manual and automatic. Manual machines require the operator to manually feed the paper into the machine and operate the machine to make the caps. Automatic machines are more efficient and can produce a higher volume of caps with less labor.

- Manual machines are typically used for small-scale production or for making custom caps.

- Automatic machines are typically used for large-scale production of standard caps.

6. What are the common problems that can occur during the production of paper caps, and how can they be solved?

There are a number of common problems that can occur during the production of paper caps, including:

- Wrinkles in the paper

- Tears in the paper

- Uneven creases

- Poor adhesion of the glue

These problems can be solved by:

- Using high-quality paper

- Using the correct type of glue

- Properly adjusting the machine

- Training the operators

7. What are the safety precautions that must be observed when operating a paper cap machine?

There are a number of safety precautions that must be observed when operating a paper cap machine, including:

- Wearing appropriate safety gear, such as gloves and eye protection

- Keeping the work area clean and free of debris

- Not operating the machine if it is not in good working order

- Following the manufacturer’s instructions for operating the machine

8. What is the importance of regular maintenance of paper cap machines?

Regular maintenance of paper cap machines is important to ensure that the machines are operating safely and efficiently. Maintenance tasks may include:

- Cleaning and lubricating the machine

- Inspecting the machine for wear and tear

- Replacing worn or damaged parts

- Calibrating the machine

Regular maintenance can help to prevent breakdowns, extend the life of the machine, and improve the quality of the caps produced.

9. How can you improve the efficiency of a paper cap machine?

There are a number of ways to improve the efficiency of a paper cap machine, including:

- Using high-quality paper

- Using the correct type of glue

- Properly adjusting the machine

- Training the operators

- Automating the process

By implementing these measures, you can increase the output of the machine, reduce waste, and improve the quality of the caps produced.

10. What are the future trends in the paper cap industry?

The paper cap industry is constantly evolving, with new technologies and trends emerging all the time. Some of the key trends that are expected to shape the industry in the future include:

- Increased use of automation

- Development of new and innovative materials

- Growing demand for sustainable products

- Expansion of the global market

By staying up-to-date on these trends, you can ensure that your business is well-positioned for success in the years to come.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Paper Cap Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Paper Cap Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Paper Cap Machine Operators play a pivotal role in ensuring the smooth functioning of paper cap production lines. Their key responsibilities encompass:

1. Machine Operation

Precisely operating paper cap-making machinery, including the feeder, forming device, and drying oven, to produce high-quality caps.

- Loading paper reels and accurately setting machine parameters to optimize cap production.

- Monitoring machine performance, identifying malfunctions, and promptly addressing any issues to minimize downtime.

2. Quality Control

Maintaining strict quality standards by meticulously inspecting paper caps for defects, such as creases, tears, or misalignments.

- Conducting regular quality checks and implementing corrective measures to enhance product quality.

- Collaborating with quality assurance teams to identify and resolve quality-related problems.

3. Production Monitoring

Optimizing production efficiency by closely monitoring output levels and implementing productivity improvement strategies.

- Setting and tracking production targets, analyzing performance metrics, and identifying areas for improvement.

- Communicating production updates to supervisors and maintaining accurate production records.

4. Safety and Maintenance

Adhering to established safety protocols to ensure a safe work environment while operating machinery and handling materials.

- Performing routine maintenance tasks, such as cleaning and lubricating equipment, to prevent breakdowns.

- Reporting maintenance issues promptly and assisting with repairs to minimize production disruptions.

Interview Tips

To ace the interview for a Paper Cap Machine Operator position, it’s essential to demonstrate a combination of technical skills, attention to detail, and a commitment to quality.

1. Research the Company and Industry

Familiarize yourself with the company’s background, industry trends, and the specific requirements of the role.

- Research the company’s website, LinkedIn page, and industry publications to gain insights into their operations.

- Identify any industry-specific certifications or specialized knowledge that may be relevant to the position.

2. Highlight Relevant Experience and Skills

Emphasize your experience operating paper cap machines or similar production equipment.

- Quantify your accomplishments and provide specific examples of your contributions to production efficiency and quality control.

- Showcase your proficiency in identifying and resolving machine malfunctions, as well as your ability to maintain a safe work environment.

3. Demonstrate Quality Focus

Convey your commitment to producing high-quality products and your ability to identify and address defects.

- Explain your understanding of quality control procedures and your experience in implementing corrective actions.

- Emphasize your attention to detail and your ability to maintain consistent standards in a fast-paced production environment.

4. Show Enthusiasm and Willingness to Learn

Express your eagerness to work in a production setting and your willingness to learn new techniques and technologies.

- Convey your interest in the industry and your passion for producing high-quality products.

- Indicate your willingness to undergo training and development programs to enhance your skills and knowledge.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Paper Cap Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!