Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Paper Core Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

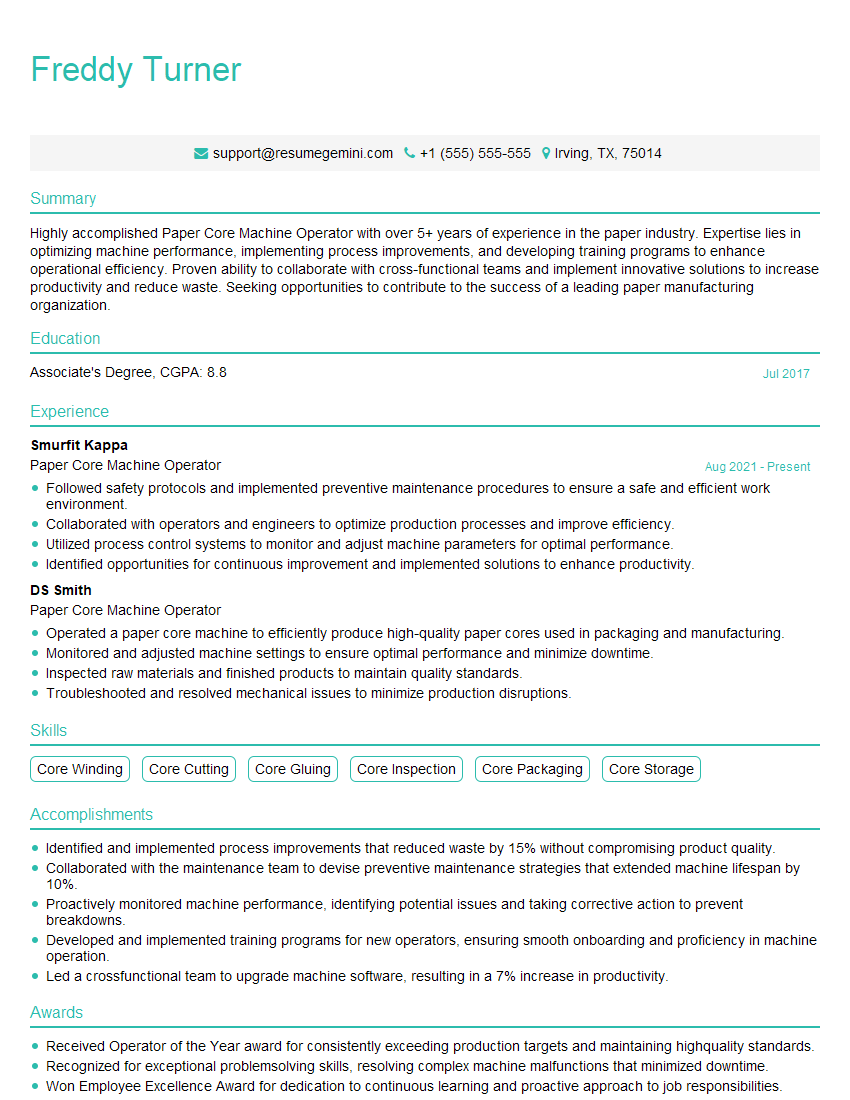

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Paper Core Machine Operator

1. What are the key responsibilities of a Paper Core Machine Operator?

The primary responsibilities of a Paper Core Machine Operator include:

- Operating and monitoring the paper core machine to produce paper cores of various sizes and specifications

- Maintaining the machine by performing regular inspections, cleaning, lubrication, and adjustments

- Monitoring product quality and making adjustments as needed

- Troubleshooting and resolving any issues that arise during the production process

- Ensuring that the machine operates safely and efficiently

2. Describe the different types of paper cores you have experience producing. What are their different uses?

Types of Paper Cores

- Spiral Cores: Used for paper rolls, packaging films, and industrial applications

- Convolute Cores: Used for packaging textiles, carpets, and floor coverings

- Sonotubes: Used for concrete forms, mailing tubes, and construction projects

- Edge Protectors: Used to protect rolls of paper and film during storage and transportation

Their Uses

- Supporting and protecting paper rolls

- Providing structural support for various packaging applications

- Serving as mailing tubes and concrete forms

- Protecting edges of paper and film rolls from damage

3. What safety precautions are important to follow when operating a Paper Core Machine?

Key safety precautions include:

- Wearing appropriate protective gear such as gloves, safety glasses, and earplugs

- Keeping guards and safety devices in place and operational

- Inspecting the machine regularly for any potential hazards

- Following proper lockout/tagout procedures during maintenance

- Being aware of moving parts and potential pinch points

- Never attempting to clear a jam or adjust the machine while it is running

4. How do you ensure that the paper cores meet the specified quality standards?

To ensure quality, I follow these steps:

- Regularly checking the machine settings and calibrations

- Monitoring the paper core dimensions and surface finish

- Performing sample testing to verify strength and durability

- Inspecting cores for any defects or imperfections

- Making adjustments to the machine or process as needed

5. What is the importance of maintaining the Paper Core Machine?

Regular maintenance is crucial because it:

- Keeps the machine running smoothly and efficiently

- Reduces the risk of breakdowns and costly repairs

- Extends the lifespan of the machine

- Ensures the production of high-quality paper cores

- Helps maintain a safe and productive work environment

6. Describe how you troubleshoot and resolve common problems that may occur during paper core production.

When troubleshooting, I follow these steps:

- Identifying the problem and its potential causes

- Consulting technical documentation or manuals

- Inspecting the machine for loose connections, worn parts, or other issues

- Testing different solutions to determine the most effective

- Making necessary adjustments or repairs

- Documenting the issue and resolution for future reference

7. How do you stay up-to-date on the latest advancements in paper core machine technology and best practices?

To stay current, I engage in the following:

- Attending industry conferences and workshops

- Reading trade publications and technical articles

- Participating in online forums and discussions

- Seeking guidance from colleagues and industry experts

- Exploring new technologies and their potential benefits

8. What is the role of automation in modern paper core machine operations?

Automation plays a significant role by:

- Increasing production efficiency and throughput

- Reducing manual labor and potential errors

- Improving safety by eliminating hazardous tasks

- Providing real-time monitoring and data collection

- Facilitating data-driven decision-making and process optimization

9. How do you prioritize your responsibilities and manage your time effectively in a fast-paced paper core production environment?

My approach to prioritizing and time management includes:

- Establishing clear priorities based on deadlines and importance

- Creating a structured schedule and sticking to it as much as possible

- Breaking down large tasks into smaller, manageable chunks

- Delegating tasks to others when appropriate

- Taking short breaks throughout the day to maintain focus and productivity

10. What qualities make you an ideal candidate for this Paper Core Machine Operator position?

My qualifications and experience align well with the requirements of this position:

- Extensive experience operating and maintaining paper core machines

- Proven ability to produce high-quality paper cores consistently

- Strong understanding of paper core machine technology and best practices

- Excellent troubleshooting and problem-solving skills

- Commitment to safety and maintaining a clean and organized work environment

- Ability to work independently and as part of a team

- Excellent communication and interpersonal skills

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Paper Core Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Paper Core Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Paper Core Machine Operators play a crucial role in the paper manufacturing process. They are responsible for operating and monitoring paper core machines, ensuring the smooth production of high-quality paper cores. These paper cores are essential components of many paper products, such as toilet paper, paper towels, and wrapping paper.

1. Machine Operation

Paper Core Machine Operators are tasked with operating and maintaining the paper core machine. This involves setting up the machine, loading raw materials, and adjusting machine settings to produce paper cores that meet specific requirements.

- Set up and adjust the paper core machine according to production specifications

- Monitor and maintain the machine to ensure optimal performance

- Troubleshoot and resolve any issues that may arise during operation

2. Quality Control

Paper Core Machine Operators are responsible for ensuring the quality of the paper cores produced. They conduct regular inspections and tests to verify that the cores meet the required standards for strength, diameter, and surface finish.

- Inspect paper cores for defects, such as cracks, dents, or uneven surfaces

- Conduct tests to measure the strength and durability of paper cores

- Make adjustments to the machine or process as needed to maintain product quality

3. Production Monitoring

Paper Core Machine Operators monitor the production process to ensure that the machine is operating efficiently and producing the desired output. They track production rates, identify bottlenecks, and make adjustments as needed to optimize productivity.

- Monitor production rates and identify areas for improvement

- Troubleshoot any issues that may affect production efficiency

- Make adjustments to the machine or process to maximize output

4. Maintenance and Repairs

Paper Core Machine Operators perform routine maintenance and repairs on the equipment they operate. This involves cleaning, lubricating, and replacing worn or damaged parts to ensure the machine’s longevity and performance.

- Clean and lubricate the machine according to maintenance schedules

- Inspect and replace worn or damaged parts to prevent breakdowns

- Follow safety protocols and procedures during maintenance and repairs

Interview Tips

To prepare for an interview for a Paper Core Machine Operator position, it is important to research the company and the specific role you are applying for. You should also practice your answers to common interview questions and prepare questions to ask the interviewer. Here are some additional tips to help you ace the interview:

1. Research the Company and Role

Before the interview, take the time to learn about the company, its culture, and the specific Paper Core Machine Operator role you are applying for. Visit the company’s website, read industry news, and connect with current or former employees on LinkedIn to gain insights into the organization and the position.

- Research the company’s history, mission, and values

- Review the job description and identify the key responsibilities and qualifications

- Connect with people in the industry to learn about the company’s reputation and culture

2. Practice Your Answers

It is helpful to practice your answers to common interview questions before the interview. This will give you confidence and help you deliver clear and concise responses. Consider preparing for questions such as:

- “Tell me about your experience operating paper core machines.”

- “How do you ensure the quality of the paper cores you produce?”

- “What are some of the challenges you have faced as a Paper Core Machine Operator?”

3. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions that demonstrate your knowledge of the industry and the company. This is also an opportunity to clarify any details about the role or the company’s expectations.

- “What are the company’s goals for this role in the next year?”

- “What are some of the opportunities for professional development within the organization?”

- “How does the company ensure the safety of its employees?”

4. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview. This shows that you respect the interviewer’s time and that you are serious about the position.

- Choose clothing that is clean, pressed, and appropriate for a professional setting

- Arrive at the interview location at least 10 minutes early

- Greet the interviewer with a firm handshake and a smile

5. Be Confident and Enthusiastic

Confidence and enthusiasm can make a positive impact on the interviewer. Believe in your abilities and convey your excitement about the opportunity. Show that you are eager to learn and contribute to the company.

- Maintain eye contact, speak clearly, and articulate your answers with confidence

- Highlight your skills and experience that are relevant to the role

- Express your enthusiasm for the company and the opportunity

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Paper Core Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!