Feeling lost in a sea of interview questions? Landed that dream interview for Paper Goods Machine Set-Up Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Paper Goods Machine Set-Up Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

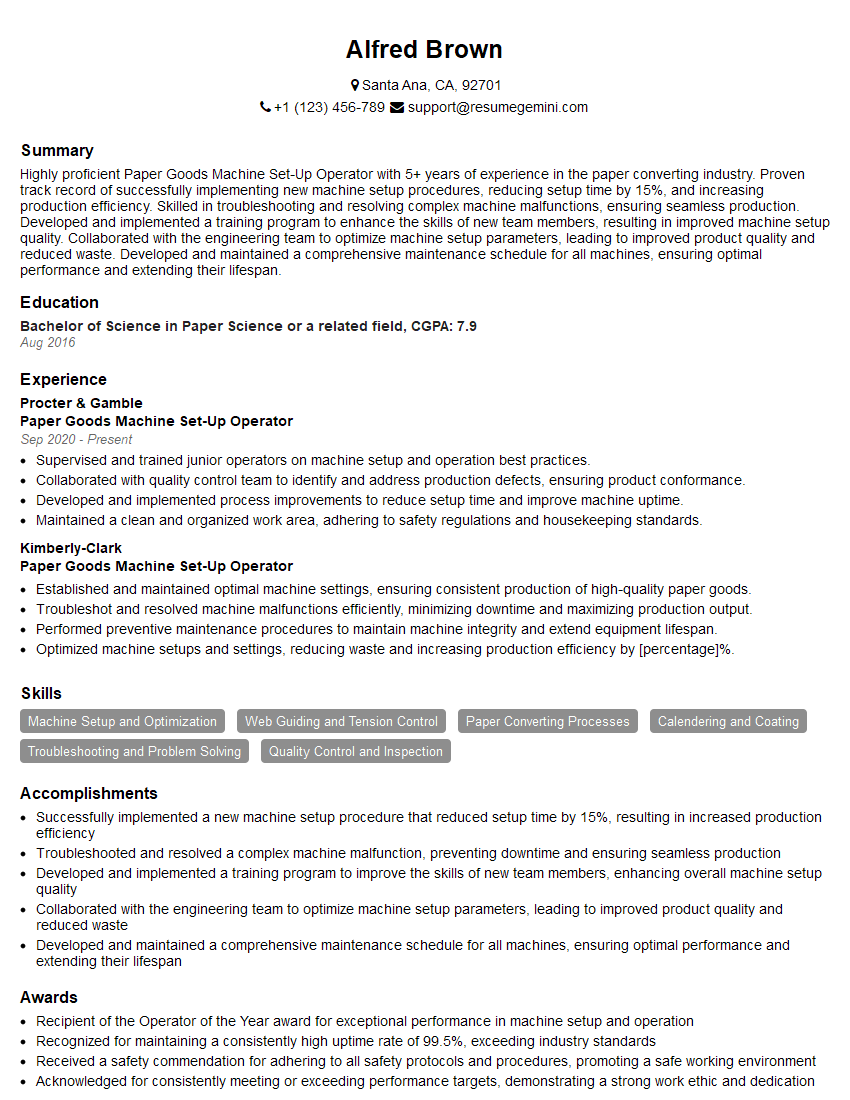

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Paper Goods Machine Set-Up Operator

1. Describe the process of setting up a paper goods machine.

The process of setting up a paper goods machine involves several steps:

- Preparation: Gather necessary materials, tools, and instructions.

- Machine inspection: Check the machine for any damages or issues.

- Preparation of paper rolls: Load and secure paper rolls onto the machine.

- Setting up printing unit: Install and align printing plates, adjust ink flow, and ensure proper registration.

- Configuring converting unit: Set up knives, creasers, or other converting tools to produce the desired paper goods.

- Test run: Run the machine at a low speed to check for any errors or adjustments needed.

- Fine-tuning: Make necessary adjustments to optimize machine performance, such as speed, pressure, and temperature.

2. How do you resolve common problems encountered during machine setup, such as paper jams or uneven printing?

Troubleshooting Paper Jams

- Check if the paper is loaded correctly and not wrinkled.

- Inspect rollers and belts for any debris or damage.

- Adjust paper tension to ensure it’s not too loose or tight.

- Clean sensors and other components that detect paper movement.

Resolving Uneven Printing

- Calibrate the printing plates and adjust their position.

- Ensure ink flow is consistent and adjust ink settings if needed.

- Check the temperature and humidity of the printing environment.

- Contact the machine manufacturer for technical assistance.

3. Explain how you ensure the safety and accuracy of the machine during setup and operation.

To ensure safety and accuracy, I follow these practices:

- Safety first: Wear appropriate PPE, such as gloves, safety glasses, and earplugs.

- Proper training: Receive and maintain up-to-date training on machine operation.

- Regular maintenance: Adhere to maintenance schedules to prevent breakdowns and ensure accuracy.

- Quality control: Conduct regular inspections of paper goods and monitor machine performance to maintain quality standards.

- Proper documentation: Record setup parameters, maintenance activities, and any issues encountered.

4. Describe the types of paper goods machines you have experience with and how they differ in their operation.

I have worked with various paper goods machines, including:

- Corrugators: Produce corrugated cardboard by combining multiple layers of paper.

- Flexographic printers: Use flexible printing plates to print designs on paper.

- Die-cutters: Use dies to cut and shape paper into various forms.

- Slitters: Cut large rolls of paper into narrower rolls.

- Sheeter: Cut paper into sheets of specific sizes.

Each machine has unique setup procedures, printing capabilities, and converting options.

5. How do you maintain and calibrate the machine to ensure optimal performance?

I perform regular maintenance and calibration to ensure optimal machine performance:

- Lubrication: Grease and oil moving parts to prevent wear and tear.

- Cleaning: Remove dust, ink, and other debris to prevent jams and ensure accuracy.

- Calibration: Use precision tools and techniques to adjust sensors, print heads, and other components.

- Performance monitoring: Track machine parameters and identify areas for improvement.

- Collaboration: Consult with maintenance technicians and engineers for technical support.

6. Explain how you optimize machine setup to minimize waste and maximize efficiency.

To minimize waste and maximize efficiency, I implement the following strategies:

- Proper planning: Determine the most efficient setup based on production requirements.

- Accurate measurements: Use precise tools and techniques to ensure correct setup and reduce trial-and-error.

- Minimizing adjustments: Fine-tune machine settings during initial setup to reduce the need for subsequent adjustments.

- Training and communication: Involve operators in the setup process to ensure consistent execution.

- Continuous improvement: Regularly review setup procedures and identify opportunities for waste reduction.

7. Describe your experience with different types of paper materials and how you adapt the machine setup accordingly.

I have experience with a wide range of paper materials, including:

- Cardboard: Requires higher pressure and slower speeds during setup.

- Tissue paper: Needs delicate handling and careful adjustment of tension.

- Coated paper: Requires specific settings to ensure ink adhesion.

- Recycled paper: May have variations in thickness and roughness, requiring adjustments to feeding and cutting.

I adapt machine setup by adjusting parameters such as pressure, speed, and temperature based on the material properties.

8. How do you work effectively in a team environment to ensure smooth machine operation?

In a team environment, I contribute by:

- Collaboration: Communicate clearly and work closely with other operators and supervisors.

- Problem-solving: Identify and resolve issues promptly to minimize downtime.

- Knowledge sharing: Train and support new team members, sharing my expertise.

- Safety awareness: Maintain a safe work environment and adhere to safety protocols.

- Continuous improvement: Participate in process improvement initiatives to enhance team performance.

9. Can you provide an example of a time when you successfully resolved a complex issue with a paper goods machine?

During a production run, the machine experienced a sudden drop in print quality. I followed a systematic troubleshooting process:

- Inspection: Checked for any visible damage or misalignment.

- Diagnosis: Used gauges and measurement tools to identify the source of the issue.

- Repair: Adjusted printing plates, cleaned sensors, and recalibrated the machine.

- Testing: Conducted a test run to verify the issue was resolved.

By promptly addressing the issue, I minimized production downtime and maintained product quality.

10. What are your career goals and how does this role align with them?

My career goals include:

- Advancement: Seek opportunities for growth within the paper goods industry.

- Technical expertise: Develop my skills in paper goods machine setup and maintenance.

- Process improvement: Contribute to the optimization of machine operations and efficiency.

- Leadership: Aspire to lead and mentor a team of machine operators.

This role aligns with my goals by providing a challenging environment where I can develop my technical skills, contribute to process improvement, and potentially move into a leadership position.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Paper Goods Machine Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Paper Goods Machine Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Paper Goods Machine Set-Up Operators are responsible for setting up, operating, and maintaining machines that produce paper goods such as napkins, paper towels, toilet paper, and tissues. They also monitor the quality of the products produced and make adjustments to the machines as needed. Key responsibilities of a Paper Goods Machine Set-Up Operator include:

1. Set up and operate paper goods machines

This includes loading the machines with paper rolls, setting the machine parameters, and starting the machines. They also monitor the machines during operation and make adjustments as needed to ensure that the products are produced to the correct specifications.

2. Maintain paper goods machines

This includes cleaning the machines, lubricating the moving parts, and replacing worn or damaged parts. They also perform regular maintenance checks to identify potential problems and prevent breakdowns.

3. Monitor the quality of paper goods produced

This includes inspecting the products for defects and taking corrective action if necessary. They also monitor the quality of the raw materials used in the production process.

4. Troubleshoot and repair paper goods machines

This includes identifying the cause of problems and taking steps to repair the machines. They also consult with maintenance technicians if necessary.

Interview Tips

To ace an interview for a Paper Goods Machine Set-Up Operator position, it’s important to prepare thoroughly and highlight your skills and experience. Here are some tips to help you prepare:

1. Research the company and the position

This will help you better understand the company’s culture and the specific requirements of the position. You can research the company’s website, Glassdoor, and other online resources.

2. Practice answering common interview questions

There are many common interview questions that you may be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in a clear and concise manner.

3. Highlight your skills and experience

When answering interview questions, be sure to highlight your skills and experience that are relevant to the position. For example, you can talk about your experience setting up and operating paper goods machines, your knowledge of paper goods production processes, and your ability to troubleshoot and repair machines.

4. Be prepared to talk about your safety record

Working as a Paper Goods Machine Set-Up Operator can be a hazardous job, so it’s important to have a good safety record. Be prepared to talk about your safety record and the steps you take to ensure your own safety and the safety of others.

Next Step:

Now that you’re armed with the knowledge of Paper Goods Machine Set-Up Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Paper Goods Machine Set-Up Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini