Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Paper Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Paper Machine Operator so you can tailor your answers to impress potential employers.

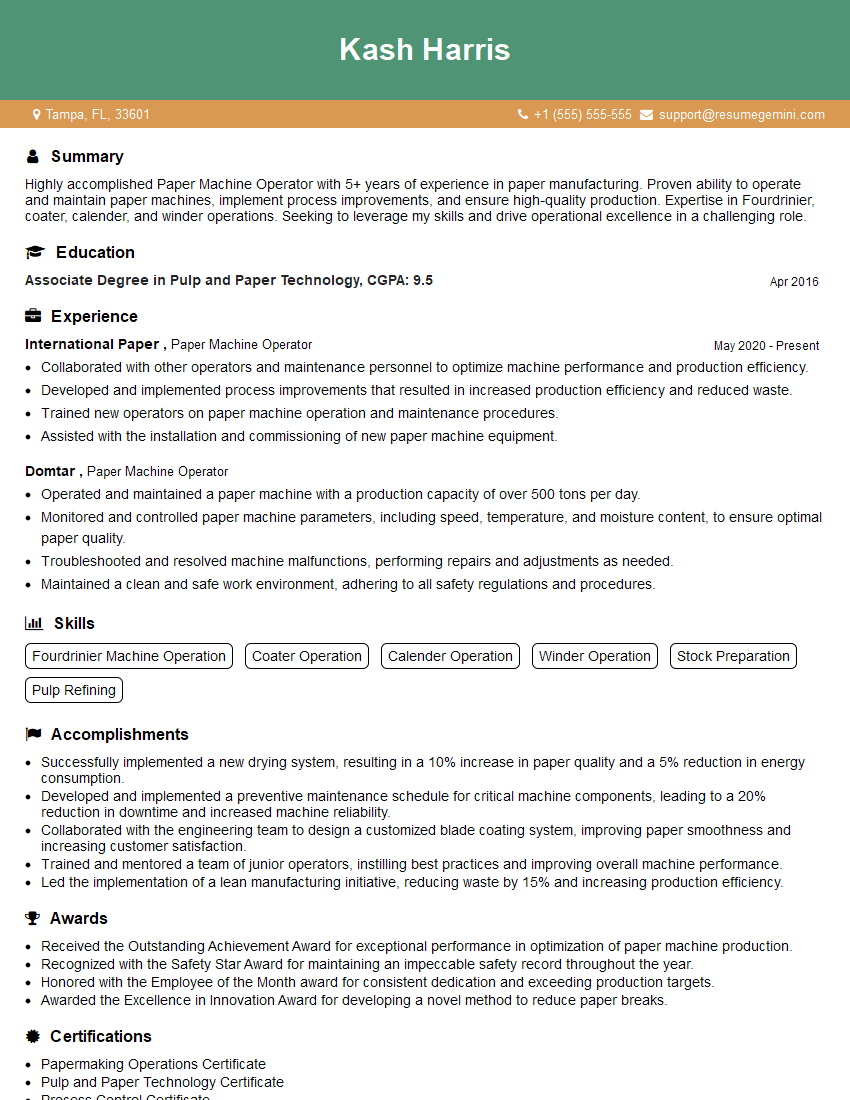

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Paper Machine Operator

1. Explain the process of headbox consistency control?

Headbox consistency control maintains the desired pulp consistency in the headbox to ensure uniform paper quality.

- Consistency measurement: A consistency transmitter measures the pulp consistency in the headbox.

- Control loop: The consistency transmitter sends a signal to the controller, which compares it to the desired setpoint.

- Valve adjustment: Based on the deviation, the controller adjusts the opening or closing of a dilution valve.

- Dilution addition: If the consistency is too high, the valve opens to add more dilution water to the headbox.

- Stock addition: If the consistency is too low, the valve closes to reduce dilution and allow more stock to enter the headbox.

2. Describe the function of the wet end of a paper machine?

Pulp preparation:

- Mixing: The wet end blends different pulp grades and additives to create the desired paper furnish.

- Dilution: Water is added to adjust the pulp consistency for paper formation.

Papermaking:

- Headbox: The headbox distributes the pulp slurry onto the forming wire to create the paper web.

- Wire section: The forming wire drains water from the web, allowing fibers to bond and form the initial sheet.

Water removal:

- Press section: A series of press rolls further dewater the paper web.

- Vacuum box: A vacuum is applied to the web to enhance water removal.

3. What are the key factors that affect the moisture content of paper?

- Press section efficiency: Proper press roll pressure and roll condition minimize moisture retention.

- Drying section temperature and airflow: Higher temperatures and stronger air circulation promote evaporation.

- Paper grade and basis weight: Different grades and weights absorb and release moisture differently.

- Environmental conditions: Humidity and temperature in the mill can influence paper moisture content.

- Roll winding tension: Excessive tension can trap moisture in the roll.

4. How do you troubleshoot a paper break in the dry end?

- Check dry end equipment: Inspect rolls, bearings, and belts for damage or misalignment.

- Examine paper web: Look for wrinkles, tears, or foreign objects that may have caused a break.

- Adjust tension: Ensure proper tension throughout the dry end to prevent web stretching or snapping.

- Monitor drying temperature: Excessive heat can weaken the web and increase the risk of breaks.

- Check moisture content: Too high or low moisture levels can make the paper brittle or susceptible to breaks.

5. Explain the role of the calender stack in paper production?

- Smoothing: Calender rolls apply pressure to the paper web, flattening fibers and creating a smooth surface.

- Glossing: Higher pressures and heated calender rolls impart a glossy or sheen finish to the paper.

- Compacting: Calendering reduces paper bulk and increases density, improving strength and printability.

- Modifying surface properties: Calendering can adjust the smoothness, friction, and ink absorbency of the paper.

6. How do you ensure the quality of paper during production?

- Raw material inspection: Checking pulp quality, additives, and chemicals.

- Process monitoring: Observing headbox consistency, press section dewatering, and drying section conditions.

- Inline testing: Using sensors to measure moisture content, basis weight, and ash content.

- Sampling and testing: Taking samples throughout the process to evaluate physical properties and compare against specifications.

- Machine adjustments: Making necessary adjustments to press roll pressure, drying temperatures, or chemical dosages.

7. What are the common safety hazards in a paper mill and how can they be mitigated?

Mechanical hazards:

- Moving machinery

- Roll handling

- Wet and slippery floors

Chemical hazards:

- Caustic chemicals

- Bleaching agents

- Dust and fumes

Mitigations:

- Machine guards and interlocks

- Proper training and PPE

- Ventilation and exhaust systems

- Spill response plans

- Regular safety inspections

8. Describe the maintenance procedures for a paper machine?

- Regular inspections: Checking rolls, bearings, belts, and other components for wear or damage.

- Cleaning and lubrication: Maintaining clean equipment to prevent buildup and ensure smooth operation.

- Roll grinding: Resurfacing rolls to restore their smoothness and performance.

- Planned shutdowns: Scheduling downtime for major repairs and overhauls.

- Predictive maintenance: Using sensors and data analysis to identify potential issues before they cause failures.

9. How do you handle high-speed paper defects such as wrinkles or uneven moisture?

- Inspect the paper web: Identify the location and nature of the defect.

- Adjust machine settings: Make corrections to headbox consistency, press section pressure, or drying conditions.

- Use defect removal equipment: Employ devices like air knives or vacuum suction to remove wrinkles or excess moisture.

- Monitor sensor data: Track moisture content and web tension to identify areas requiring adjustments.

- Consult with supervisors or maintenance personnel: Seek guidance and support for resolving complex issues.

10. What are the latest advancements in papermaking technology that you are aware of?

- Automation and control systems: Improved process control and optimization.

- Advanced drying technology: Energy-efficient and more precise drying methods.

- Coating and surface treatment: Enhancing paper properties and functionality.

- Lightweight and high-strength papers: Meeting the demands of modern packaging and printing industries.

- Sustainable papermaking: Focus on reducing environmental impact and conserving resources.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Paper Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Paper Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Paper Machine Operators are responsible for the operation and maintenance of paper manufacturing machines. They ensure that the machines are running smoothly and efficiently, and produce paper that meets the desired quality standards.

1. Operating and Monitoring Paper Machines

Paper Machine Operators are responsible for operating and monitoring paper machines. They must be able to understand the machine’s controls and make adjustments as needed to maintain production. They also need to be able to identify and troubleshoot problems with the machine.

- Operate paper machines to produce paper and paperboard products.

- Monitor machine performance and make adjustments to ensure that the machines are operating at the correct speed and temperature.

2. Maintaining Paper Machines

Paper Machine Operators are responsible for maintaining paper machines. They must be able to perform routine maintenance tasks, such as cleaning and lubrication, and be able to identify and troubleshoot problems with the machine. They also need to be able to replace worn parts and make repairs as needed.

- Maintain paper machines by performing routine maintenance, such as cleaning and lubrication.

- Troubleshoot and repair problems with paper machines.

3. Controlling Quality

Paper Machine Operators are responsible for controlling the quality of the paper produced by the machine. They must be able to take samples of the paper and test it to ensure that it meets the desired specifications. They also need to be able to make adjustments to the machine as needed to improve the quality of the paper.

- Monitor the quality of the paper produced by the machines and make adjustments as needed.

- Take samples of the paper and test it to ensure that it meets the desired specifications.

4. Safety and Environment

Paper Machine Operators must be able to work safely around the machine and follow all safety procedures. They must also be aware of the environmental regulations that apply to the operation of the machine and take steps to comply with those regulations.

- Follow all safety procedures and wear the required personal protective equipment.

- Be aware of the environmental regulations that apply to the operation of the machine and take steps to comply with those regulations.

Interview Tips

Preparing for a Paper Machine Operator interview can be daunting, but by following these tips, you can increase your chances of success.

1. Researching the Company and Position

Before you go to your interview, take some time to research the company and the position you’re applying for. This will help you understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, LinkedIn, and Glassdoor.

- Visit the company’s website to learn about their history, products, and services.

- Read industry news and articles to stay up-to-date on the latest trends.

- Network with people who work in the paper industry.

2. Practicing Your Answers

Once you have a good understanding of the company and the position, it’s time to practice your answers to common interview questions. This will help you feel more confident and prepared during your interview.

- Start by writing down a list of potential questions that you might be asked.

- Practice answering these questions out loud.

- Get feedback from a friend or family member on your answers.

3. Dressing Professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes and shoes. Avoid wearing anything too revealing or casual.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Avoid wearing anything too revealing or casual.

4. Being Punctual

Punctuality shows that you respect the interviewer’s time. Arrive for your interview on time, or even a few minutes early. If you’re running late, call or email the interviewer to let them know.

- Plan your route to the interview in advance.

- Give yourself plenty of time to get there.

- If you’re running late, call or email the interviewer to let them know.

5. Being Confident

Confidence is key in any interview. Believe in yourself and your abilities. Make eye contact with the interviewer and speak clearly and confidently. Don’t be afraid to ask questions or to share your thoughts and ideas.

- Practice your answers to common interview questions.

- Visualize yourself being successful in the interview.

- Dress professionally and arrive on time.

Next Step:

Now that you’re armed with the knowledge of Paper Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Paper Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini