Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Paper Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

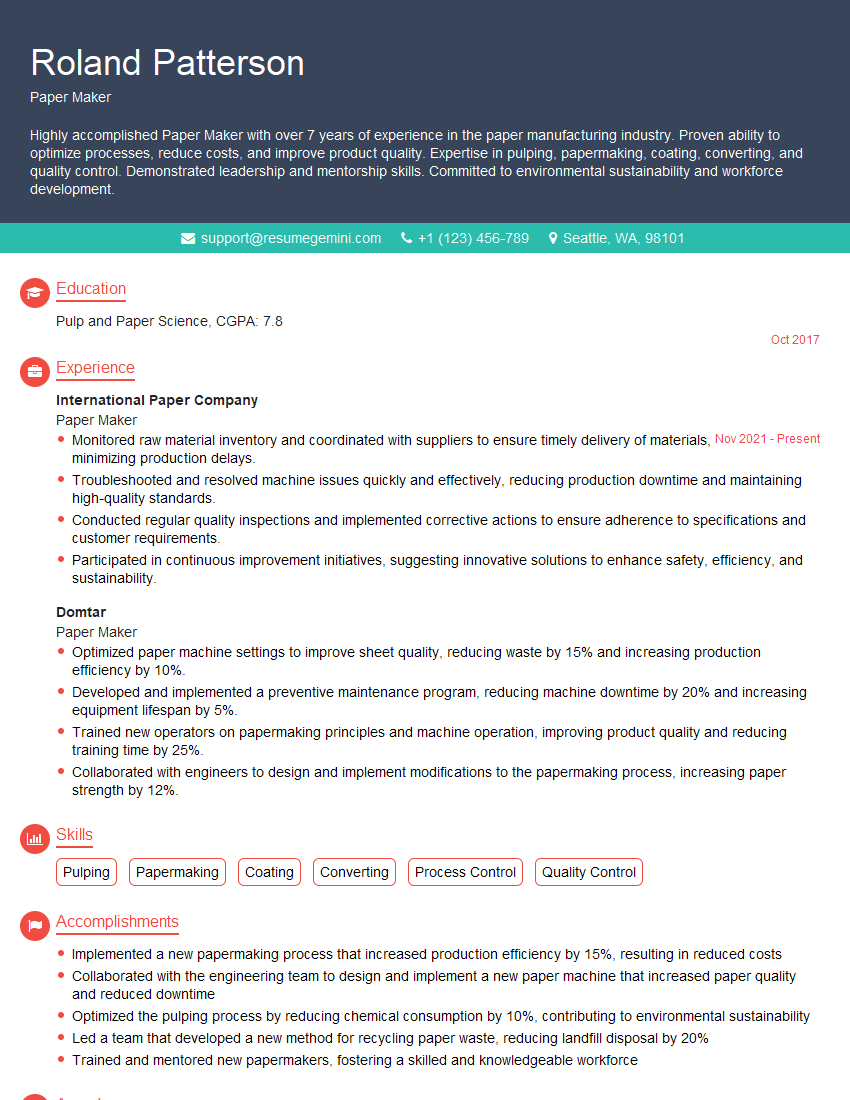

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Paper Maker

1. Explain the process of papermaking from raw materials to finished product?

The papermaking process involves several stages:

- Pulping: Raw materials (wood, recycled paper, etc.) are broken down into a slurry called pulp.

- Screening: The pulp is screened to remove impurities and ensure uniform consistency.

- Paper Machine: The pulp is fed into a paper machine, where it is spread out into a thin sheet.

- Pressing: The sheet is pressed to remove excess water and increase its density.

- Drying: The paper is heated to evaporate remaining moisture and stabilize its properties.

- Finishing: The paper is calendared (smoothed), coated, or treated as required to meet specific end-use requirements.

2. What are the key factors that determine paper quality?

Raw Materials

- Type and quality of wood or fibers used

- Pulp composition and purity

Manufacturing Process

- Machine design and efficiency

- Temperature and pressure during pressing and drying

- Additives and coatings applied

3. Describe the different types of papermaking machines?

- Fourdrinier Machine: Forms the paper sheet from a suspension of pulp in water.

- Cylinder Machine: Forms the sheet on a revolving cylinder covered with a wire mesh.

- Twin Wire Machine: Forms the sheet between two parallel wire meshes.

- Board Machine: Used to produce thicker paperboard products.

4. What are the common defects that occur in papermaking and how are they typically resolved?

- Broke: Paper web breaks during production, causing downtime and waste. Resolved by improving machine efficiency and raw material quality.

- Holes: Defects in the paper sheet caused by inconsistencies in the pulp mixture or foreign particles. Resolved by fine-tuning the screening process.

- Paper Curl: Paper sheet curls after drying due to uneven moisture distribution. Resolved by adjusting drying conditions.

- Roughness: Uneven surface of the paper. Resolved by optimizing calendering process.

5. How do you ensure the consistency and quality of paper products?

- Raw Material Inspection: Monitor and control the quality of wood and recycled materials used.

- Process Control: Use automated systems to maintain optimal temperature, pressure, and machine settings.

- Testing and Inspection: Regularly conduct physical and chemical tests on paper samples to verify specifications.

- Data Analysis: Track and analyze production data to identify areas for improvement and maintain consistency.

6. What are the environmental considerations in modern papermaking?

- Sustainable Timber Sourcing: Use of certified wood from well-managed forests.

- Wastewater Treatment: Treatment and disposal of wastewater from the papermaking process.

- Energy Efficiency: Optimization of energy usage in machines and processes.

- Recycled Content: Use of recycled paper to reduce landfill waste.

7. Describe the role of additives in papermaking and provide examples.

- Fillers: Add bulk to the paper and improve its opacity (e.g., calcium carbonate).

- Pigments: Provide color or whiteness to the paper (e.g., titanium dioxide).

- Wet-Strength Agents: Increase the strength of the paper when wet (e.g., rosin).

- Sizing Agents: Reduce the absorption of liquids into the paper (e.g., starch).

8. What are the different coating methods used in papermaking and their applications?

- Blade Coating: A blade spreads a coating mixture onto the paper surface for high-gloss finishes.

- Air Knife Coating: An air knife removes excess coating mixture for more uniform and matte finishes.

- Size Press Coating: A roller applies a coating mixture in the size press section, resulting in improved ink receptivity.

- Cast Coating: A high-speed process that produces a very smooth and glossy surface.

9. Explain the concept of paper grammage and its significance in paper selection.

Paper grammage refers to the weight of one square meter of paper. It influences the thickness, strength, and opacity of the paper.

- Higher Grammage: Thicker, stronger, and more opaque paper, suitable for covers, business cards, and premium printing.

- Lower Grammage: Thinner, lighter, and less opaque paper, suitable for newsprint, writing paper, and envelopes.

10. What are the different types of specialty papers and their applications?

- Security Papers: Used in passports, certificates, and currency due to their tamper-resistant features.

- Filter Papers: Used in scientific and industrial applications to filter liquids and solids.

- Dielectric Papers: Used in capacitors due to their high insulation strength.

- Tissue Papers: Soft and absorbent, used in hygiene products, packaging, and wiping.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Paper Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Paper Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Paper Makers are responsible for operating and maintaining paper-making machines. They ensure that the machines run smoothly and efficiently, and that the paper produced meets the required specifications. Key job responsibilities include operating paper machines, controlling the flow of raw materials, adjusting machine settings, performing maintenance and repairs, monitoring paper quality, and ensuring safety in the workplace.

1. Machine Operation

Paper Makers are responsible for operating paper machines. They start and stop the machines, adjust the speed and tension of the paper web, and make other adjustments to ensure that the paper is produced to the desired specifications.

- Start and stop paper machines

- Adjust the speed and tension of the paper web

- Make other adjustments to ensure that the paper is produced to the desired specifications

2. Raw Material Control

Paper Makers are responsible for controlling the flow of raw materials into the paper machine. They monitor the levels of pulp, water, and other chemicals in the machine, and make adjustments as needed to ensure that the paper is produced to the desired specifications.

- Monitor the levels of pulp, water, and other chemicals in the machine

- Make adjustments as needed to ensure that the paper is produced to the desired specifications

3. Machine Maintenance and Repairs

Paper Makers are responsible for performing maintenance and repairs on the paper machine. They identify and troubleshoot problems, and make repairs as needed to keep the machine running smoothly.

- Identify and troubleshoot problems

- Make repairs as needed to keep the machine running smoothly

4. Paper Quality Monitoring

Paper Makers are responsible for monitoring the quality of the paper produced by the machine. They inspect the paper for defects, and make adjustments to the machine as needed to ensure that the paper meets the required specifications.

- Inspect the paper for defects

- Make adjustments to the machine as needed to ensure that the paper meets the required specifications

5. Safety Assurance

Paper Makers are responsible for ensuring safety in the workplace. They follow all safety procedures, and wear appropriate safety gear.

- Follow all safety procedures

- Wear appropriate safety gear

Interview Tips

To prepare for a Paper Maker interview, it is important to research the company and the position. You should also practice answering common interview questions. Here are some tips to help you ace your interview.

1. Do your research

Before your interview, take some time to research the company and the position. This will help you understand the company’s culture, values, and goals. You should also learn as much as you can about the position, including the key job responsibilities and the qualifications required.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people in your network who work for the company

2. Practice answering common interview questions

There are a number of common interview questions that you can expect to be asked. It is important to practice answering these questions in advance so that you can deliver your answers confidently and concisely. Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with paper making?

- What are your salary expectations?

3. Be prepared to talk about your experience

In your interview, you will be asked about your experience with paper making. Be prepared to talk about your skills and knowledge in detail. You should also be able to provide examples of your work that demonstrate your abilities.

- Highlight your experience with operating paper machines

- Discuss your knowledge of paper making processes

- Provide examples of your work that demonstrate your skills and abilities

4. Be professional and enthusiastic

First impressions matter, so it is important to be professional and enthusiastic in your interview. Dress appropriately, arrive on time, and be polite and respectful to everyone you meet. You should also be prepared to answer questions about your qualifications and experience, and to ask questions about the company and the position.

- Dress appropriately

- Arrive on time

- Be polite and respectful

- Be prepared to answer questions about your qualifications and experience

- Ask questions about the company and the position

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Paper Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!