Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Paper Pattern Inspector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

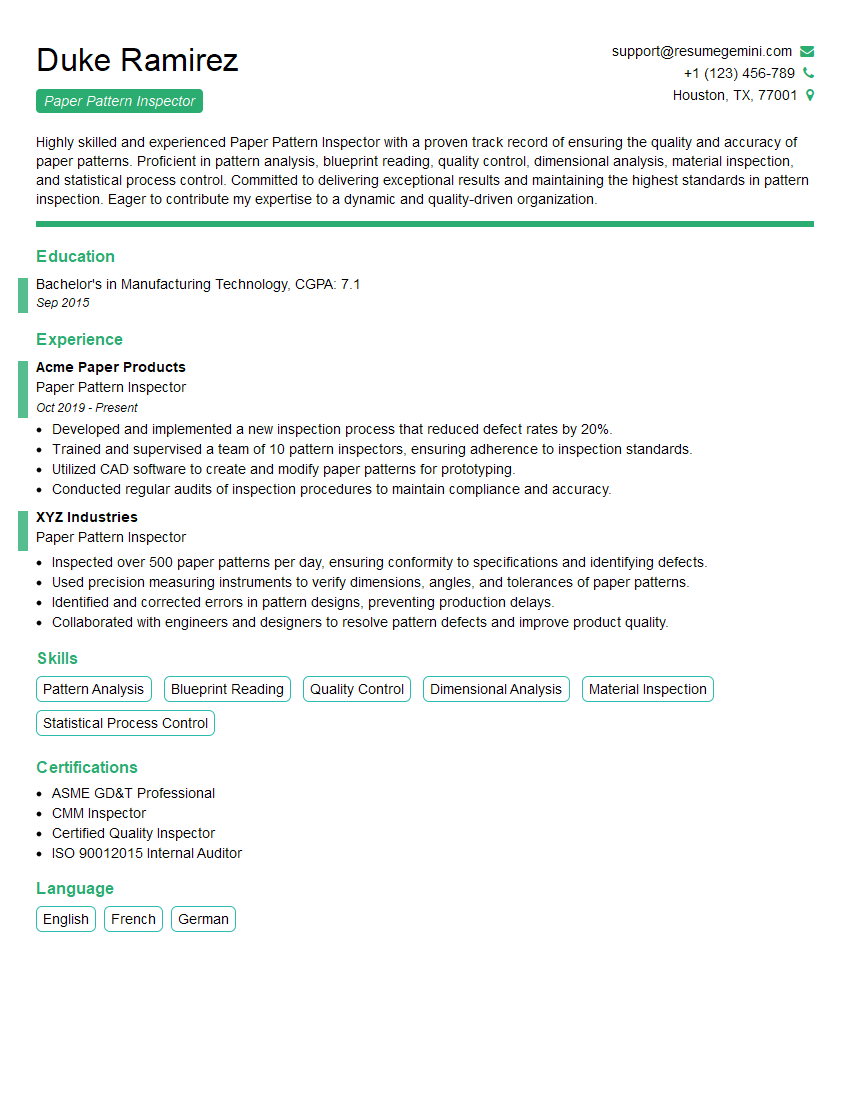

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Paper Pattern Inspector

1. Explain the importance of accurate paper pattern inspection in the garment manufacturing process?

Accurate paper pattern inspection is crucial in the garment manufacturing process for several reasons:

- Ensures Garment Quality: Paper patterns serve as the blueprint for garment construction. Errors in the pattern can lead to faulty garments, affecting the overall quality and aesthetics of the final product.

- Prevents Production Delays: Incorrect patterns can cause delays in production as adjustments need to be made. Timely pattern inspection helps identify errors early on, preventing costly production stoppages.

- Reduces Material Waste: Accurate patterns minimize fabric waste by ensuring efficient cutting and sewing. Inaccurate patterns can result in excess fabric usage and increased production costs.

2. Describe the key aspects of paper pattern inspection?

Visual Inspection:

- Checking line accuracy, pattern shape, and dimensions

- Inspecting for notches, symbols, and seam allowances

Dimensional Inspection:

- Measuring lengths, angles, and distances using rulers, calipers, or measuring machines

- Comparing measurements to specified tolerances

Functional Inspection:

- Assessing the pattern’s functionality by folding and assembling it

- Verifying fit, alignment, and ease of construction

3. What factors should be considered when inspecting paper patterns?

- Pattern Design: Complexity of the pattern, number of pieces, and fabric properties.

- Inspection Standards: Established guidelines and tolerances for pattern accuracy.

- Tools and Equipment: Availability and calibration of measuring instruments.

- Production Timeline: Time constraints and deadlines for pattern inspection.

4. Explain how you ensure consistent and accurate pattern inspection?

- Standardized Procedures: Establishing clear inspection criteria and following a systematic process.

- Trained Inspectors: Providing comprehensive training and ensuring inspectors are well-versed in pattern inspection techniques.

- Inspection Equipment Maintenance: Regularly calibrating and maintaining measuring tools for precision and accuracy.

- Quality Control System: Implementing a system for regular pattern inspections and monitoring inspection results.

- Continuous Improvement: Seeking opportunities to improve inspection methods and processes through feedback and analysis.

5. How do you communicate inspection findings to the pattern maker or design team?

- Written Reports: Providing detailed reports documenting inspection results, including any errors or deviations.

- Visual Aids: Using sketches, annotations, or photographs to illustrate errors or areas of concern.

- Meetings: Attending meetings to discuss inspection findings, suggest improvements, and collaborate on solutions.

6. Describe your experience in using pattern inspection software?

I have experience working with [Software Name] for pattern inspection. This software allows me to:

- Digital Pattern Manipulation: Load and manipulate digital patterns for inspection.

- Automated Measurements: Use software tools to measure lengths, angles, and distances accurately.

- Error Detection: Identify errors and deviations from specified tolerances using software algorithms.

- Reporting: Generate detailed inspection reports with visual aids and error logs.

7. How do you stay up-to-date with the latest inspection techniques and industry best practices?

- Industry Conferences: Attend industry conferences and seminars to learn about new inspection methods and technologies.

- Trade Publications: Read trade publications and industry magazines to stay informed about advancements in pattern inspection.

- Online Resources: Utilize online resources, forums, and webinars to access up-to-date information and best practices.

- Continuing Education: Pursue continuing education courses or certifications to enhance my knowledge and skills.

8. How do you handle discrepancies or errors identified during pattern inspection?

Upon identifying discrepancies or errors during pattern inspection, I follow these steps:

- Verification: Double-checking the error to ensure its accuracy.

- Documentation: Recording the error in detail and providing visual evidence.

- Communication: Reporting the error to the appropriate personnel (e.g., pattern maker, design team).

- Resolution: Collaborating with the relevant parties to identify the root cause and determine the necessary corrective actions.

- Follow-up: Monitoring the implementation of corrective actions and verifying that the error has been rectified.

9. What are the common challenges you encounter in paper pattern inspection?

- Complex Patterns: Handling intricate patterns with numerous pieces and tight tolerances.

- Fabric Variability: Accounting for variations in fabric properties that can affect pattern accuracy.

- Time Constraints: Meeting tight inspection deadlines while maintaining precision.

- Team Communication: Ensuring effective communication of inspection findings and collaborating with other team members.

- Continuous Improvement: Staying updated with evolving industry standards and best practices.

10. How do you maintain a high level of focus and accuracy over extended periods of inspection?

- Regular Breaks: Taking short breaks to prevent fatigue and maintain focus.

- Attention to Detail: Cultivating a keen eye for detail and paying attention to all aspects of the pattern.

- Systematic Approach: Following a standardized inspection process to ensure thoroughness.

- Physical Comfort: Ensuring a comfortable work environment with proper lighting and ergonomic equipment.

- Continuous Improvement: Regularly reviewing inspection methods and seeking ways to enhance accuracy.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Paper Pattern Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Paper Pattern Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Paper Pattern Inspector holds a crucial role in quality control by meticulously examining paper patterns against specifications. Here are some key job responsibilities that define their role:

1. Inspecting Patterns

Inspect paper patterns for dimensional accuracy, angles, stitching holes, and overall quality to ensure conformance to design standards.

- Use measuring tools such as rulers, calipers, and gauges to verify exact measurements.

- Identify and mark deviations from specifications for further correction.

2. Verifying Label Placement

Inspect and verify the placement of labels on the patterns, ensuring they align correctly and comply with industry standards.

- Check label orientation, size, and content for accuracy.

- Mark or flag any discrepancies or non-conformances.

3. Evaluating Pattern Grain

Examine and assess the grain of the paper pattern to ensure it meets specified requirements.

- Inspect the paper for consistency in grain direction and alignment with design specifications.

- Identify and mark any instances of incorrect grain orientation.

4. Maintaining Quality Standards

Uphold and enforce quality standards by adhering to established procedures and guidelines.

- Inspect patterns meticulously to ensure compliance with customer and industry standards.

- Document and report any deviations or defects promptly.

Interview Tips

To ace the interview for a Paper Pattern Inspector position, it is crucial to prepare thoroughly and showcase your relevant skills and experience. Here are some interview preparation tips:

1. Research the Company and Role

Understand the company’s background, industry, and specific requirements for the Paper Pattern Inspector role. Research the company’s website, LinkedIn page, and any relevant industry news.

- Highlight specific examples of your experience that align with the job responsibilities.

- Demonstrate your knowledge of the industry and quality control best practices.

2. Practice Answering Common Interview Questions

Prepare for common interview questions such as: “Describe your experience in inspecting paper patterns” or “How do you handle non-conforming patterns?.”

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Provide specific examples to illustrate your skills and accomplishments.

3. Emphasize Attention to Detail

Highlight your meticulous attention to detail and ability to identify and correct errors in patterns.

- Describe your process for verifying measurements and ensuring accuracy.

- Share examples of how you have identified and resolved pattern defects.

4. Showcase Quality Control Experience

Emphasize your experience in maintaining quality standards and implementing quality control procedures.

- Discuss your understanding of industry standards and regulations.

- Describe your role in developing and implementing quality control measures.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement.

- Inquire about the company’s commitment to quality and its expectations for pattern accuracy.

- Ask about the team culture and opportunities for professional development.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Paper Pattern Inspector, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Paper Pattern Inspector positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.