Are you gearing up for an interview for a Paper Roller position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Paper Roller and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

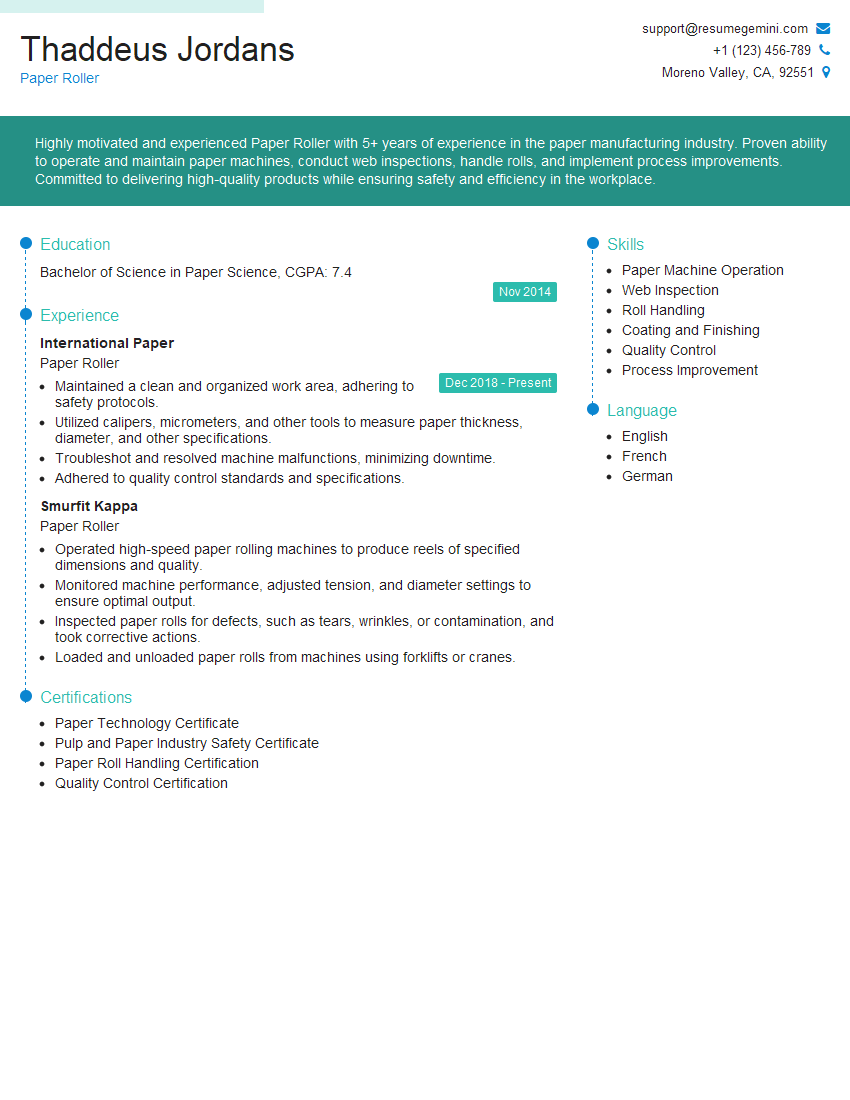

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Paper Roller

1. Can you describe the primary responsibilities of a Paper Roller?

As a Paper Roller, my key responsibilities include:

- Loading and feeding paper rolls into the printing press

- Adjusting paper tension and alignment to ensure accurate printing

- Monitoring paper levels and replenishing rolls as needed

- Maintaining and troubleshooting the paper handling system

- Inspecting paper quality and reporting any defects

2. What safety protocols must be followed while operating a paper rolling machine?

Understanding and adhering to safety regulations

- Wearing appropriate safety gear, including gloves and eye protection

- Following lockout/tagout procedures before performing maintenance

- Keeping work areas clean and free of tripping hazards

Emergency preparedness

- Knowing the location of emergency stop buttons and fire extinguishers

- Being aware of potential hazards, such as paper jams and electrical malfunctions

- Responding promptly to any safety issues

3. How do you ensure that the paper is loaded and tensioned correctly to avoid printing errors?

To ensure proper paper loading and tensioning, I follow these steps:

- Inspecting the roll for any visible damage or defects

- Loading the roll onto the machine and securing it with the appropriate clamps

- Adjusting the tension settings based on the paper type and printing requirements

- Running a test print to verify proper tension and alignment

- Making fine adjustments as needed to optimize print quality

4. What troubleshooting steps would you take if the paper roller is not feeding paper properly?

To troubleshoot paper feeding issues, I would follow a systematic approach:

- Checking the paper roll tension and adjusting it if necessary

- Inspecting the paper path for any obstructions or debris

- Verifying that the paper is loaded correctly and is aligned properly

- Checking the machine’s sensors and controls for any malfunctions

- Restarting the machine and running a test print to identify any persistent issues

5. How do you maintain the paper rolling machine to ensure its optimal performance?

Regular maintenance is essential to ensure the optimal performance of the paper rolling machine. I would follow a comprehensive maintenance schedule that includes:

- Cleaning the paper path and removing any dust or debris

- Inspecting and lubricating moving parts, such as gears and bearings

- Checking the tension settings and adjusting them as needed

- Calibrating the sensors and controls to ensure accuracy

- Performing regular maintenance checks to identify any potential issues

6. What do you do if you notice a drop in paper quality or consistency?

If I notice a drop in paper quality or consistency, I would take the following steps:

- Inspect the paper roll for any visible defects or damage

- Check the paper tension and adjust it if necessary

- Examine the printing press settings and ensure that they are optimized for the paper type

- Clean the paper path and remove any dust or debris

- Contact the supplier or manufacturer for further assistance if the issue persists

7. Describe your experience working with different types of paper materials and their properties

Throughout my career, I have worked with a wide range of paper materials, including:

- Offset paper: Understanding its absorbency, brightness, and smoothness

- Newsprint: Familiar with its low GSM and high opacity

- Coated paper: Managing its glossy finish and susceptibility to scratches

- Specialty paper: Handling its unique textures, weights, and applications

8. How do you ensure that the printing process is running smoothly and efficiently?

To ensure a smooth and efficient printing process, I prioritize the following:

- Maintaining optimal paper tension and alignment

- Monitoring print quality and making adjustments as needed

- Replenishing paper rolls promptly to avoid interruptions

- Communicating any potential issues to the press operator

- Following established production schedules

9. How do you handle situations when there is a high volume of printing orders?

When faced with a high volume of printing orders, I would:

- Prioritize orders based on deadlines and customer requirements

- Work efficiently and maintain a steady pace

- Collaborate with the press operator to optimize the printing process

- Stay organized and focused on completing orders accurately

- Manage time effectively to meet production targets

10. What are your strengths and weaknesses as a Paper Roller?

Strengths:

- Strong attention to detail and accuracy

- Excellent hand-eye coordination and dexterity

- Proficient in troubleshooting and resolving technical issues

- Ability to work independently and as part of a team

- Committed to safety and maintaining a clean and organized work area

Weaknesses:

- May require additional experience with specialized paper handling equipment

- Balancing multiple tasks and working under pressure can be challenging at times

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Paper Roller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Paper Roller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities:

A Paper Roller operates a machine in the paper, film or plastics industries that trims, cuts, or wraps paper rolls or sheets. They can work in diverse settings, including paper mills, paper goods production facilities, and warehouses.

1. Machine Operation

A Paper Roller is responsible for setting up, operating, and monitoring machines. They perform tasks such as:

- Loading and unloading paper rolls or sheets

- Adjusting machine speed and tension

- Inspecting paper quality and making adjustments as needed

2. Product Handling

Paper Rollers are also responsible for handling finished products. This includes:

- Trimming and cutting paper rolls or sheets

- Wrapping and packaging finished products

- Moving and stacking products

3. Maintenance and Repair

Paper Rollers are responsible for performing basic maintenance and repairs on the machines they operate. This includes:

- Cleaning and lubricating machines

- Fixing minor breakdowns

- Replacing parts

4. Quality Control

Paper Rollers are responsible for checking the quality of finished products and making adjustments as needed. This includes:

- Inspecting products for defects

- Measuring size and thickness

- Ensuring products meet specifications

Interview Tips:

To make a positive impact on hiring managers, candidates should approach the interview process strategically, with preparation and confidence. Here are crucial interview preparation tips:

1. Research the Company and Position

Investigate the company’s background, mission, values, and recent news, as well as the specific role you are applying for. This demonstrates your enthusiasm for the opportunity and sets you apart as a serious candidate.

2. Practice Common Interview Questions

Review common interview questions and formulate thoughtful responses that highlight your skills, experience, and fit for the position. Use the STAR method (Situation, Task, Action, Result) to provide structured and compelling answers.

3. Prepare Questions for the Interviewer

Asking well-thought-out questions about the company, the role, and the industry displays your engagement and interest in the opportunity. It also gives you a chance to clarify any aspects of the position that you may have.

4. Dress Professionally and Arrive Punctually

Dress appropriately for the interview and arrive on time. First impressions matter! Maintain a positive and professional demeanor throughout the meeting.

5. Follow Up

After the interview, promptly send a thank-you note to the interviewer(s) reiterating your interest in the position and thanking them for their time. This reinforces your professionalism and leaves a lasting positive impression.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Paper Roller interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.