Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Paper Tube Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Paper Tube Machine Operator so you can tailor your answers to impress potential employers.

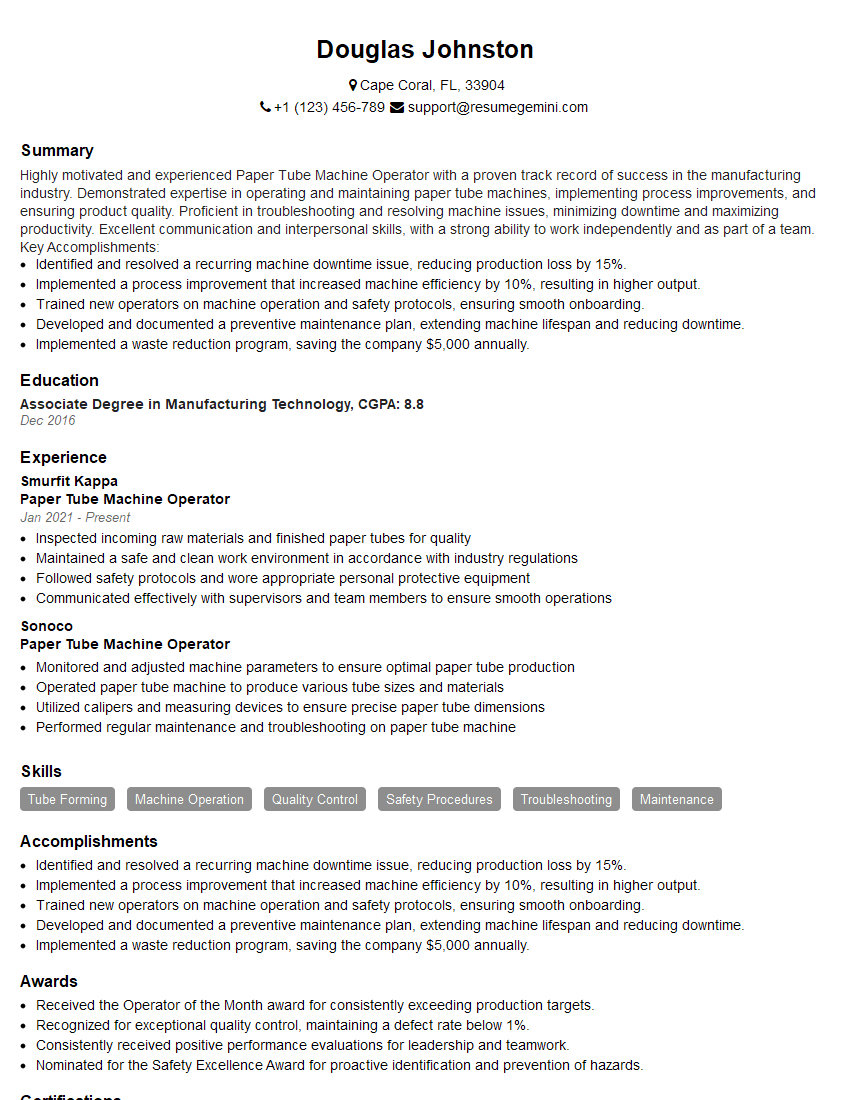

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Paper Tube Machine Operator

1. Describe the process of setting up a paper tube machine.

The process of setting up a paper tube machine involves the following steps:

- Mount the paper roll: Load the paper roll onto the unwind stand and secure it in place.

- Thread the paper web: Guide the paper web through the machine’s rollers and tensioning devices.

- Set the machine parameters: Enter the desired tube dimensions, winding speed, and other settings into the machine’s control system.

- Calibrate the machine: Run a short test to ensure the machine is producing tubes with the correct dimensions and quality.

2. What are the different types of paper that can be used on a paper tube machine?

- Kraft paper: A strong and durable paper made from virgin wood pulp, commonly used for structural applications.

- Recycled paper: Paper made from recycled materials, offering a more sustainable option but may have lower strength.

- Coated paper: Paper with a special surface coating, such as polyethylene or wax, providing resistance to moisture or chemicals.

- Specialty papers: Papers with specific properties, such as flame retardation, antimicrobial resistance, or high-temperature resistance, for specialized applications.

3. Explain the importance of tension control in paper tube production.

Tension control is crucial in paper tube production for several reasons:

- Tube quality: Proper tension ensures that the paper web is wound tightly and evenly, preventing wrinkles, tears, or distortions in the finished tube.

- Machine efficiency: Excessive tension can cause the machine to run slower or even break the paper web, reducing productivity.

- Safety: High tension can put excessive stress on the machine components, potentially leading to safety hazards.

4. Describe the maintenance procedures required for a paper tube machine.

- Regular cleaning: Remove paper dust, debris, and adhesives from the machine to prevent blockages and ensure smooth operation.

- Lubrication: Lubricate moving parts, such as bearings and gears, to reduce friction and prevent wear.

- Inspection: Regularly inspect the machine for signs of wear or damage, such as worn belts, loose screws, or damaged rollers.

- Calibration: Periodically calibrate the machine’s sensors and controls to ensure accuracy and consistent production.

5. What are some common troubleshooting techniques for a paper tube machine?

- Paper jams: Check for wrinkles, tears, or obstructions in the paper web and adjust tension settings as needed.

- Tube distortion: Inspect the winding head for proper alignment and adjust tension or tracking settings.

- Poor tube quality: Ensure the correct paper type is used, adjust machine parameters, or inspect for worn or damaged components.

- Machine malfunctions: Follow the manufacturer’s troubleshooting guide, check for loose connections, or contact technical support.

6. Explain the safety protocols you follow when operating a paper tube machine.

I strictly adhere to the following safety protocols:

- Proper attire: Wear appropriate clothing, gloves, and safety glasses to prevent entanglement or injury.

- Machine guarding: Ensure that all machine guards and safety devices are in place and functional.

- Lockout/tagout procedures: Follow established procedures for isolating the machine during maintenance or repairs.

- Hazard identification: Be aware of potential hazards, such as moving parts, sharp edges, or hot surfaces, and take necessary precautions.

7. Describe the different types of adhesives used in paper tube production and their applications.

- Water-based adhesives: Environmentally friendly and cost-effective, suitable for general-purpose applications.

- Solvent-based adhesives: Offer high bonding strength and fast drying times, but require proper ventilation due to VOC emissions.

- Hot-melt adhesives: Provide strong and durable bonds, ideal for high-speed production lines, but require specialized equipment.

- Pressure-sensitive adhesives: Self-adhesive materials that form a bond upon application of pressure, suitable for labels and packaging.

8. Explain the factors that affect the diameter and wall thickness of a paper tube.

- Paper width: Wider paper rolls produce larger diameter tubes.

- Paper thickness: Thicker paper results in thicker tube walls.

- Tension settings: Higher tension wraps the paper more tightly, reducing tube diameter and increasing wall thickness.

- Winding speed: Slower winding speeds allow for more precise control of tube dimensions.

9. Describe the quality control procedures you implement to ensure the production of defect-free paper tubes.

- Raw material inspection: Check incoming paper rolls for defects, such as tears, wrinkles, or uneven thickness.

- In-process inspections: Monitor tube dimensions, wall thickness, and surface quality during production.

- Final inspection: Conduct a thorough inspection of finished tubes for any imperfections or deviations from specifications.

- Statistical process control: Use statistical tools to analyze production data and identify any areas for improvement.

10. Explain the role of automation in paper tube production and its benefits.

Automation plays a crucial role in paper tube production, offering several benefits:

- Increased efficiency: Automated machines can produce tubes faster and more consistently than manual processes.

- Improved accuracy: Automated controls ensure precise tube dimensions and winding parameters.

- Reduced labor costs: Automation reduces the need for manual labor, freeing up workers for other tasks.

- Enhanced safety: Automated machines minimize the risk of accidents or injuries by eliminating manual handling.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Paper Tube Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Paper Tube Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Paper Tube Machine Operators are responsible for operating and maintaining paper tube machines. They monitor the production process, make adjustments to the machine settings, and ensure that the finished product meets quality standards. Key job responsibilities include:

1. Machine Operation

intro paragraph

- Set up and operate paper tube machines

- Monitor the production process

- Make adjustments to machine settings

- Inspect finished products

2. Machine Maintenance

intro paragraph

- Perform routine maintenance on paper tube machines

- Troubleshoot and repair machine problems

- Keep machine logs

3. Quality Control

intro paragraph

- Inspect finished products for quality

- Maintain records of quality inspections

- Take corrective action to improve product quality

4. Safety

intro paragraph

- Follow safety procedures

- Wear personal protective equipment

- Report any safety hazards

Interview Tips

Preparing for an interview for a Paper Tube Machine Operator position requires proper understanding of the role and tailoring your answers to demonstrate relevant skills and experience. Here are some interview tips to help you ace the interview:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific Paper Tube Machine Operator position you are applying for. This will help you understand the company’s culture, values, and the specific requirements of the role. You can gather information from the company’s website, LinkedIn page, and any available job description.

2. Practice Answering Common Interview Questions

Prepare for common interview questions by practicing your answers beforehand. Some of the most common questions you may encounter include:

- Tell me about your experience operating paper tube machines.

- What are some of the challenges you have faced as a Paper Tube Machine Operator?

- How do you ensure the quality of the finished products?

- What are your strengths and weaknesses as a Paper Tube Machine Operator?

3. Emphasize Relevant Skills and Experience

Highlight your relevant skills and experience that match the requirements of the Paper Tube Machine Operator position. Quantify your accomplishments with specific examples and metrics whenever possible. For instance, you could mention the number of paper tubes you produced per hour or the percentage improvement you achieved in product quality.

4. Be Prepared to Discuss Safety Procedures

As safety is crucial in this role, be prepared to discuss your understanding and adherence to safety procedures. Explain the specific safety measures you have implemented in your previous job and how you ensured a safe work environment.

5. Show Enthusiasm and Interest

Throughout the interview, demonstrate your enthusiasm and genuine interest in the Paper Tube Machine Operator position. Ask thoughtful questions about the company and the role, and express your eagerness to contribute your skills and experience to the team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Paper Tube Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.